Now there are many companies or individuals that recycle electronic materials. They use various ways or other information channels to recycle these electronic materials in the market. Although the recycling of electronic materials is a good way to save social resources, many companies and individuals are flocking to the hidden windfall profits.

First of all, let's understand the acquisition of electronic materials divided into what?

1, large enterprises stock electronic components and materials. Many of the electronic materials stored by large enterprises are new materials available to other small and medium-sized manufacturing industries. However, large enterprises may no longer need them, or other irresistible factors may cause them not to use them. These materials will be given to companies that recycle electronic materials at a low price to reduce risks. With little packaging, these electronic materials can be sold at slightly below market prices and make a lot of money from them, because they are commonly used materials and there are no shortage of buyers.

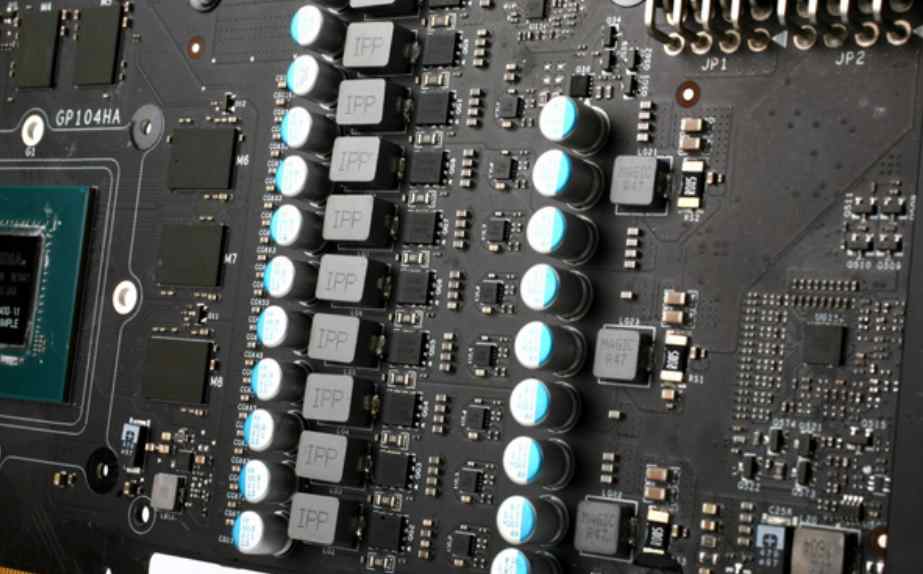

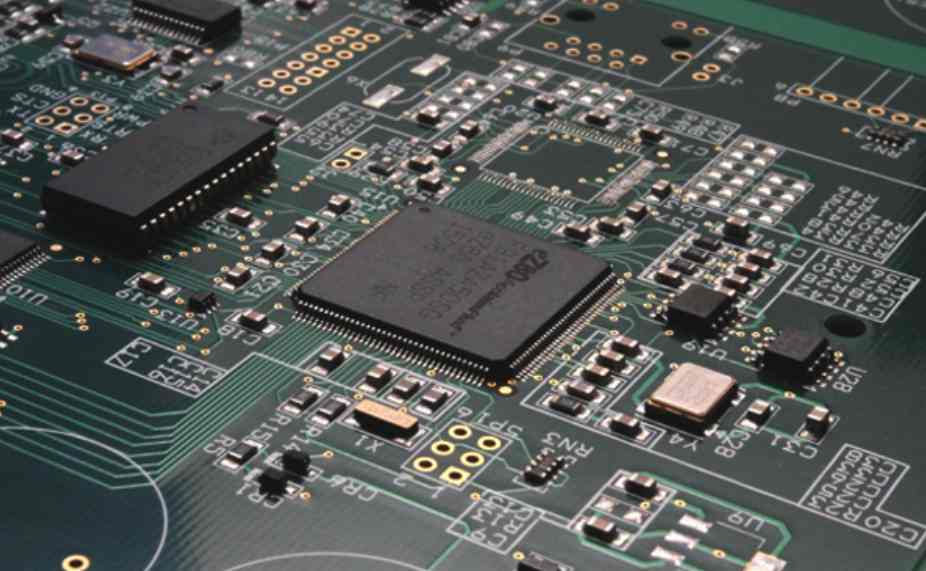

2. Scrap PCB circuit board semi-finished products recovered. These recycled semi-finished PCB products actually have many uses, such as PCB board refining metal copper, precious IC can be refined into gold, if not damaged, relatively valuable IC may be taken down, refurbished for secondary sale.

3, long-term dull materials, these materials long-term dull useless, after recycling for refurbishment, packaging, laser to erase the original screen printing, new screen printing, fill new low sales, there is a complete industry chain.

Of course there are recycled electronic materials, but there are also distributors or companies that go out and buy these materials, looking for bargains, with a gamble mentality to buy and sell these used materials or refurbished materials. If the customer uses the broken, or complaints to replace, the replacement loss is far less than the profit. Some second-hand IC refurbishment, or inventory IC refurbishment, may be used for a year and a half will not have a problem, such as the original genuine products, available to 3-5 years, these refurbished may only use 1-2 years will be aging, because the use of materials is also a life cycle. There are these sellers, there are buyers with the same idea, cheap, high profit, gambling mentality, made of finished products to the customer can realize the function at the beginning, as for the follow-up problems, follow-up. If there is any problem with these materials, there is no after-sales guarantee or technical support from the original factory, which will cause a lot of unnecessary troubles for both sides.

In the early stage of sample verification, many PCB engineers will go to some informal channels websites or dealers to purchase materials for sample verification in consideration of cost. If the subsequent products are mass-produced, they still continue to purchase electronic materials from these informal channels, which will lead to poor product consistency and stability, and it will be troublesome to track down problems. More losses are likely. Moreover, some materials are expensive to import, long production cycle, can not get the original price or suppliers can not give a good price, they will go to find other materials to buy, the purpose is to win customer orders, but this approach is not a long-term solution, there is a big problem may lead to the closure of small and medium-sized enterprises.