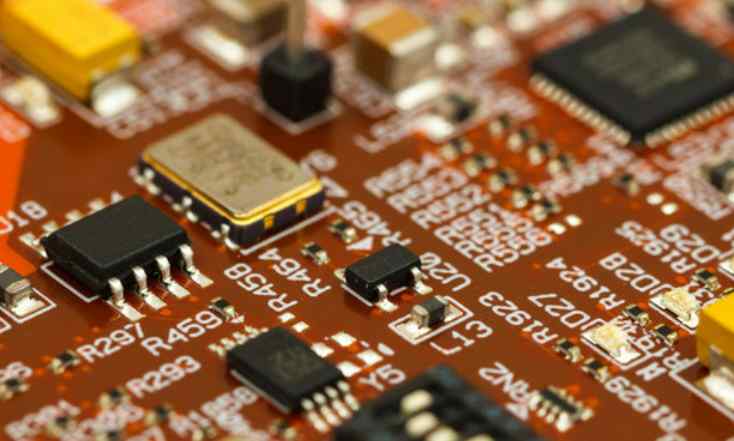

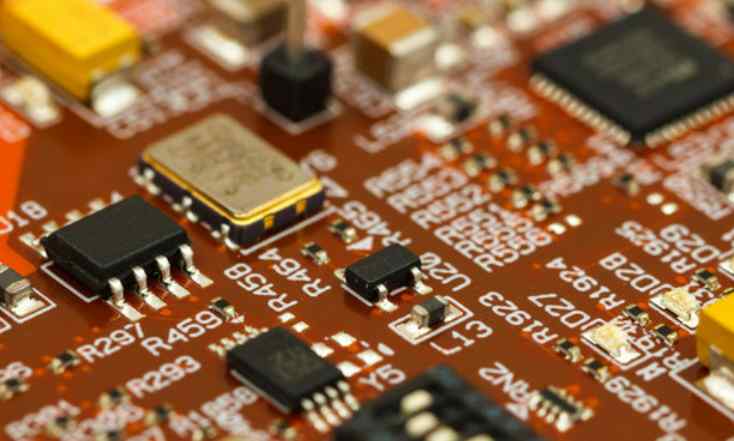

To understand the PCB board machine to establish the relevant application software, using the idea of virtual instrument, that is, through the software to achieve a variety of functions of traditional instruments, including oscilloscope, signal generator, and a variety of mathematical processing of data acquisition. During the test, the digital signal is given through the test software.

PCB board test system will have a new design idea, the use of automatic test system based on USB bus and virtual instrument design idea, give full play to the role of the computer, as far as possible by the computer to replace the idea of traditional instruments, thus reducing the volume of the instrument itself, reduce the development cost, so as to improve the efficiency of development.

Keyou Circuit 13 years professional production of PCB single-sided double-sided multilayer circuit board manufacturers, sample/batch, thermoelectric separation copper substrate,LED aluminum substrate, power circuit board, industrial circuit board, foldable metal substrate, composite bus copper substrate, etc.

After D/A conversion, the simulated excitation signal required by the test is applied to the test system, and then the test circuit is sent to the switch matrix through the test bus. When the switch matrix is connected with it, it is controlled by the microprocessor. The PCB board under test is fixed on the needle bed, and the excitation signal is applied to the corresponding position of the printed circuit board, and its response is measured by the test circuit. The analog quantity collected is sent into the core control, and the corresponding digital quantity is obtained after A/D conversion. The software on PCB is fed back and processed by PCB to determine whether the PCB board is qualified.

The online testing technology has broken through the previous method of using human eyes to detect the circuit board. The online testing technology has high efficiency, low detection rate, and realized the automation of the detection field. The detection system adopts the idea of combining with virtual instrument, reducing the hardware design and reducing the cost of the whole system.

The basic method of PCB board analog components online test and diode, triode test method, this test system is suitable for the application of small and medium enterprises. It reduces the number of unqualified products entering the next process, thus reducing the amount of rework of products, improving production efficiency, reducing the total cost of manufacturing, and improving the profits of enterprises. It is a detection technology widely used at present, and it is an efficient, high-speed and high-precision detection method.

At present, PCB board is widely used in the field of automatic testing of printed circuit board, including the testing of uninstalled components and installed components. Currently, the commonly used test methods are: on-off testing, in-circuit testing, functional testing, edge testing, optical testing and X-ray testing. Online testing is based on the specific characteristics of PCB board, select the appropriate detection method to combine one or more processes together, learn from each other, comprehensive application.

Battery circuit board: What is the battery of new energy vehicle?

Almost every once in a while, there has been a flurry of news about high-tech battery-electric circuit boards since the Tesla hype. Toyota's hydrogen electric car, aluminum battery electric car that can run 1600 kilometers, flow battery car that can run 600 kilometers on a single charge, graphene battery, aluminum ion battery... It may seem like we're stupid to be using lithium-ion batteries now, and that a new energy revolution is long overdue, but is it really as good as the news makes it sound? Let's look at the truth.

The core technology of electric vehicles is the battery, the motor, the electric control, and then the chassis technology in traditional cars and so on. Among them, motor technology is now relatively mature, electric control is also progressing with Moore's law, automotive chassis technology has been developed for so many years, not to say bottleneck.

The core problem with electric cars is the battery. The ideal battery for an electric vehicle would have the following characteristics

First, there should be enough energy density, and enough capacity per unit volume per unit weight, so as to run longer distances.

Two, there is enough power density, unit volume unit weight can produce enough power, so that the car can accelerate fast, in order to climb.

Third, the speed of energy replenishment should be fast, charging or changing the electricity should be fast, or it can only be limited to the mode of commuting in the city, running during the day and charging at night.

Four, the average cost of use should be cheap, life and price should be competitive.

Now the electric car has been on the market, there are mainly two kinds of batteries, a high-speed electric car lithium ion battery, including lithium manganese acid, lithium three yuan battery and so on. Another is lead-acid batteries for low-speed electric vehicles.