PCB circuit board processing belongs to OEM customers OEM products, different customer customized products are not the same, few shared products, on the other hand, for quality consideration, some customers may also specify the use of a manufacturer's substrate, or ink, in order to achieve its quality and cost control requirements, so there is a variable price PCB processing.

PCB price is composed of the following factors:

First, PCB materials used in the diversity of prices.

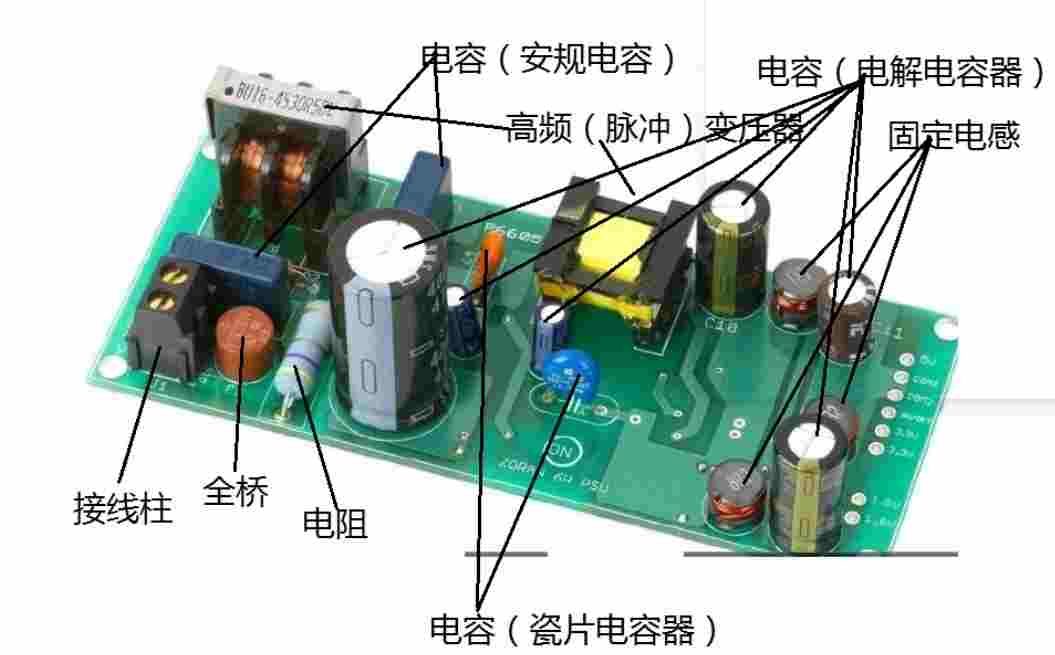

Take the common double panel as an example, the board generally has FR-4, aluminum substrate, copper substrate, etc., the board thickness from 0.6mm to 3.0mm, copper thickness from 1Oz to 3Oz different, all these in the board one item caused a huge price difference; In the welding ink, there is a certain price difference between ordinary thermosetting oil and photosensitive green oil, so the different materials cause the diversity of prices. Keyou is a professional fast production of high precision double-sided/multi-layer circuit board (1-26 layers),LED aluminum substrate, thermoelectric separation single-side/double-sided copper substrate, foldable metal substrate, special circuit board, industrial circuit board, power pcb board, medical circuit board, security PCB board, communication PCB board, automotive circuit board, instrument circuit board, military circuit board.

Second, the different production processes used by PCB result in the diversity of prices.

Different production processes result in different costs. Such as gold-plated plate and spray tin plate, the production of shape gong (milling) plate and beer (punching) plate, the use of silk screen line and dry film line will form different costs, leading to the diversity of prices.

3. Price diversity caused by different difficulty of PCB itself.

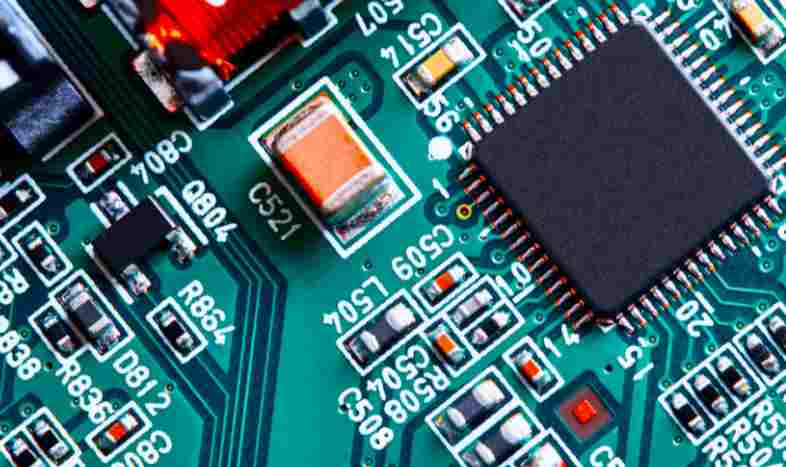

Even if the material is the same, the process is the same, but the difficulty of the PCB board itself will cause different costs. If there are 1000 holes on both types of circuit boards, the hole diameter of one board is greater than 0.6mm and that of the other board is less than 0.6mm, different drilling costs will be formed; If the other two kinds of circuit boards are the same, but the line width and line distance are different, one is greater than 0.2mm, one is less than 0.2mm, it will also cause different production costs, because the difficult board scrap rate is higher, the cost will increase, and then cause the diversity of price.

4, different customer requirements will also cause different prices.

The level of customer requirements will directly affect the finished product rate of the board factory, for example, a board according to IPC-A-600E, 98% qualified rate, but according to the class3 requirements may only 90% qualified rate, resulting in different costs of the board factory, and finally lead to the variable product price.

5. Price diversity caused by different PCB manufacturers.

Even if the same product, but because different manufacturers process equipment, technical level is different, will form different costs, many manufacturers like to produce gold plate, because the process is simple, low cost, but also some manufacturers produce gold plate, scrap that rise, resulting in higher costs, so they would rather produce tin spray plate, Thus their spray tin plate price is lower than the gold plate.

6. Price differences caused by different payment methods.

At present, PCB board manufacturers generally adjust PCB prices according to different payment methods, ranging from 5%-10%, which also causes the difference in price.

7. Regional differences lead to price diversity

At present, from the geographical position of the domestic, from the north to the south, the price is increasing, different regional prices have a certain difference, so regional different also caused the diversity of the price how to calculate PCB quotation!

1. Sheet cost (Different sheet cost is different)

2. Drilling costs (The number and size of holes affect drilling costs)

3. Process cost (different process requirements of boards lead to different process difficulties and even different prices)

4. Artificial water, electricity and management costs (this cost depends on the cost control of various factories, relatively speaking, Taiwan-funded factories on the low multinational) the basic composition of these, as for the price of raw materials, now basically stable, the possibility of price increases is unlikely.

8, as far as the plate is concerned: the price is mainly affected by the following points:

1. Plate material: FR-4, CIM-3, which is our common double-sided and multi-layer plate, its price is also related to the thickness of the plate and the thickness of copper platinum in the middle of the plate, and FR-I, CIM-1 these are our common single and plate material, and the price of this material is also much different than the above double-sided, multi-layer board.

2 is the thickness of the plate, its thickness is our common is: 0.8-1.6, and the thickness of our conventional plate price difference is not very big.

3 is the thickness of copper platinum will affect the price, copper platinum thickness is generally divided into: 18 (2/1oz), 35 (1oz) 70 (2oz), etc.

4. The suppliers of raw materials are Shengyi/Kingboard/International and so on

9, PCB circuit board production of other factors

1. If you need to look at the circuit on PCB, the price will be calculated separately if the line width and line distance (in 4/4mm) are below

2. There is BGA on the board, so the cost will rise relatively. In some places, how much is another BGA?

3 To see what is the surface treatment process, we commonly have: lead tin, lead-free spray tin, OSP, gold and so on, of course, the surface process is different, the price will be different.

Every PCB sold in the PCB industry is customized by customers. Therefore, the quotation of PCB board requires cost accounting first. At the same time, it also needs to refer to the PCB computer automatic plate calculation to make a comprehensive quotation on the utilization rate of the materials typeset on the copper clad plate of standard size.

The cost calculation of PCB industry is the most special and complex in all industries. From opening, platen, forming, to FQC, packaging, completion and warehousing, it is necessary to calculate the cost of materials, labor costs and manufacturing costs of each process input step by step, and then accumulate the cost in batches according to the product number of the order. And different types of products, the process of the standard rate will be different. For some products such as blind hole plate, gold plate, copper plate, because of its process or the particularity of all materials, it must adopt some special calculation methods. Similarly, the size of drill nozzle used in the drilling process will also affect the cost of the product, which directly affects the calculation and evaluation of WIP cost and scrap cost.