PCBA electronic product processing means that electronic product manufacturers need competent PCBA processing plants to help them complete the production of products because they do not have PCBA processing capacity or lack of processing capacity. It is a kind of PCBA outsourcing processing. Shenzhen kingford is a professional pcba OEM manufacturer with more than many years of experience in PCBA electronic products processing. Our services cover PCB design, PCB revision, component procurement, PCB manufacturing, SMT patch processing, DIP plug-in, PCBA testing (ICT line testing or FCT functional testing), finished product assembly (Box Build), warehousing logistics and other one-stop services.

pcba electronic product processing process

I. Customer data file

Customers deliver Gerber files, PCB files, coordinate diagrams, BOM list, PCBA Test Plan and other matters needing attention generated by electronic product design to us.

2. Document review

Convert the contents of data files into internal production standard documents, such as engineering documents, set sheets, etc. It is important to timely discover important issues that have not been clearly marked by customers, such as component direction, PCB process and delivery time of raw materials, and communicate with customers in advance to avoid affecting production and delivery.

Iii. Technical preparation

According to the PCBA precision, complexity and quality requirements of customers, the PCBA team studied the production plan, the issuing requirements of laser steel mesh, QA inspection standards, with the corresponding vehicle, fixture and other specific content, in order to achieve the PCBA electronic products processing straight through rate.

Iv. Material purchase and arrival

Based on customer BOM list, calculate spare parts and wastage quantity, and purchase corresponding components from original factory or large agent.

V. Material inspection and machine loading

The components will be strictly subjected to IQC (incoming material inspection), and sampled for appearance screen printing, electrical performance and mechanical performance to ensure the production quality of PCBA.

6. Start production

Submit the arrived PCB circuit boards and components to SMT and DIP production lines for pasting and welding production, strictly follow the production process method formulated by PE engineers, and pass IPQC and OQA factory inspection to ensure that the pasting and assembly requirements are met.

Vii. Testing and delivery

According to the PCBA Test scheme provided by customers, strict PCBA test was carried out, including line on-off, current/voltage value, signal noise, temperature and humidity, etc., and when necessary, help customers to carry out FCT function test and subsequent Burn In Test for the firing process. Ensure that PCBA electronic product processing quality requirements are met and delivered.

PCBA electronic product processing cycle and price

PCBA electronic products will be processed before the proofing process, the proofing process is the same as that in mass production, but because the quantity is very small, between 5-10 pieces, so the proofing price is generally more expensive than mass production. Of course, it is up to the manufacturers to decide whether to close. PCBA proofing depends on the complexity of PCB board and solder joints, the number of materials to calculate the price, generally about 500 yuan. PCBA electronic product processing price is calculated by point, different PCB board price is different. The proofing cycle of PCBA electronic products is generally about 5 days, and the production and processing cycle is generally about 20 days.

2. Price analysis of PCB board

PCB is an important electronic component, which is the carrier of electrical interconnection of electronic components. Many people are very confused about how the PCB board price is calculated. Next, Shenzhen PCB Board factory -kingford will analyze the factors affecting PCB price for you.

Factors affecting PCB price:

1. PCB circuit board materials are different

Take the common double-sided circuit board as an example. Sheet materials typically include FR-4, CIM-3, etc., from 0.6 mm to 3.0 mm thick, and copper from ½ oz to 3 oz thick. Inks for welding masks, and certain price differences between ordinary thermosetting oil and photosensitive green oil.

2. Printed circuit boards use different production processes

Different production processes lead to different costs. For example, gold plated circuit boards and tin-sprayed gongs (milled) and (stamped), and the use of printed circuits and dry film circuits all have different costs.

3. PCB circuit boards vary in difficulty

Even if the materials are the same and the process is the same, the difficulty of the PCB itself will result in different costs. If there are 1000 holes on the two boards, the hole diameter of one board is greater than 0.6 mm and the hole diameter of the other board is less than 0.6 mm, this will result in different drilling costs. For example, two types of circuit boards are the same, but the line width and line spacing are different, one type is greater than 0.2 mm, one type is less than 0.2 mm, it will also lead to different production costs, because the difficult board scrap rate is high, the cost will inevitably increase.

4. Different customer needs will lead to different prices

The level of customer demand will directly affect the output of the factory. For example, a factory requires a 98% pass rate per ipc-a-600 e, but may only have a 90% pass rate per class3 requirement.

5. PCB circuit board manufacturers vary

Even though the same product is made by different manufacturers with different process equipment and technology levels, different costs result. Nowadays, many manufacturers produce gold-plated plates because of the simple process and low cost. However, when some manufacturers produce gold-plated plates, the resulting costs will increase when scrapped. So they prefer to produce tin-sprayed panels, so their quote tin-sprayed panels is lower than gold plated panels.

6. Different payment methods

Currently, PCB board manufacturers usually adjust PCB prices according to different payment methods, ranging from 5% to 10%.

7. Different regions

At present, in the geographical location of China, the price increases from south to north, there are some price differences in different regions.

Why do you choose us to process PCBA electronic products?

1. Strength guarantee

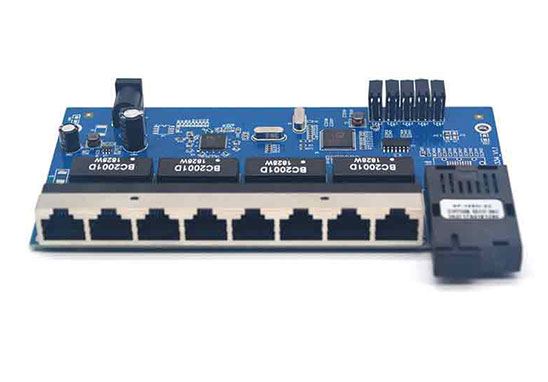

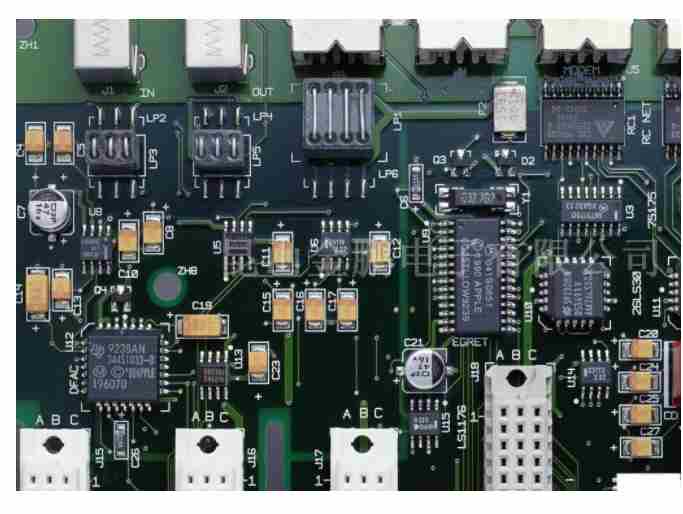

▪SMT workshop: We have imported SMT machines and several sets of optical inspection equipment, with a daily output of 4 million. Each process is equipped with QC personnel, who can keep an eye on product quality.

▪DIP production line: We have two wave-soldering machines, among which there are more than 10 old employees who have worked for more than three years. The skilled workers can weld all kinds of plug-in materials.

2. Quality assurance, cost-effective

▪ High-end equipment can stick precision shaped parts, BGA, QFN, 0201 materials. Can also template patch, loose material hand.

▪ Sample and size batch can be produced, proofing from 800 yuan, batch 0.008 yuan/point, no start-up fee.

3. Rich experience in SMT and welding of electronic products, stable delivery

▪ Accumulated SMT SMT processing services for thousands of electronic enterprises, involving many kinds of automotive equipment and industrial control motherboard. The products are often exported to Europe and the United States, and the quality can be affirmed by new and old customers.

▪ On time delivery, normal 3-5 days after complete materials, small batch can also be expedited on the same day shipment.

4. Strong maintenance ability and perfect after-sales service

▪ Experienced maintenance engineers can repair all kinds of patch welding caused by bad products, to ensure the connection rate of each piece of circuit board.

▪ 24-hour customer service staff at any time response, the fastest speed to solve your order problems.