As 2022 is approaching, we are pessimistic that smt processing costs may rise in the first half of next year. Specific has the following points are our basis. There are few industries in the world that are unaffected by the severe situation of "missing core" phenomenon, rising transportation costs and high supply chain costs that have spread throughout the pcba manufacturing industry. This is why we expect smt patch processing costs to rise. Here are some possible reasons for the potential growth.

1. Shortage of raw materials

Previously, we analyzed how the global "chip" shortage affects printed circuit boards. Raw materials of various commodities also directly affect the manufacturing cost, including printed circuit boards. The price of copper, in particular, is increasing significantly. Therefore, it is important to spend time researching alternative materials when manufacturing PCB light panels. There may be a choice of newer, more readily available materials that can be used in the production process. Because demand is not going to decrease any time soon, it is important to plan months or years ahead, especially when supplies are already limited. With Christmas abroad and Chinese New Year approaching, factories will stop production for the holidays and the market supply situation will not improve in the short term.

Second, labor remains a challenge

Labor costs and expenses vary by geography, not industry. The PCBA processing industry is facing labor shortages, which could be another factor affecting future costs. The shortage of front-line workers, such as welders and DIP plugins, is particularly acute. Quality is Paramount in this industry, so finding cheap labor substitutes is not always a viable option. Hiring inexperienced, short-term labor can make PCBA boards more prone to defects and can lead to problems in the production process that can lead to delays, outages, or worse. As labor continues to be needed to maintain quality at necessary levels, the result may be increased costs.

3. Market demand continues to soar

As more and more products require PCbas, demand will continue to rise. Due to the shortage of raw materials and labor, the supply capacity of products will be in short supply and may cause the increase of end-user costs. It's just a matter of supply versus demand.

But with the development and promotion of new containment measures, a global unlockout is something to look forward to, and we expect a correction in the middle of 2022.

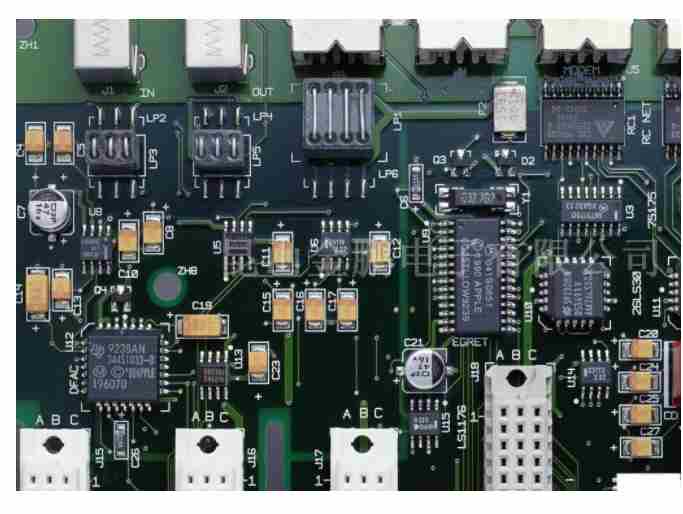

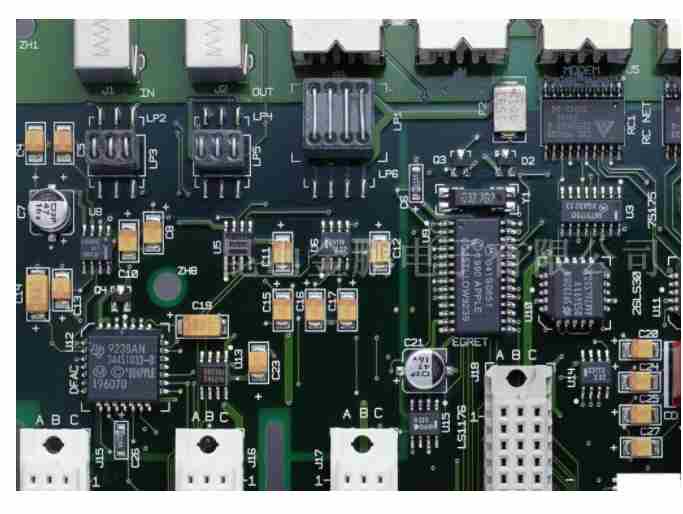

Most electronic engineering project teams will prepare quotation materials before looking for pcba processing plants. In the process of serving various customers, we also found that some customers missed some minor details. These details are also important for calculating total cost and time estimates and should be submitted at the time of the Request for Quotation (RFQ). Common omissions are as follows:

First, PCB solder resistance details

In addition to clicking Yes for the solder mask, there are some basic details that need to be shared with the account manager. These details include:

1. Welding resistance surface (top, bottom or top and bottom);

2. Type of welding resistance layer (LPI - liquid optical imaging);

3, welding resistance layer color (green, blue, black, red, white or transparent);

4, welding resistance finish paint (semi-light or matte);

5. Panels coated with solder resistance layer;

6. Panels coated with solder resistance layer;

2, surface treatment

The surface finish of pcb will affect the printing quality of solder paste in smt processing. Common surface treatments include hot air solder smoothing (HASL), electroless nickel plating (ENIG), electroless nickel palladium plating (ENEPIG), etc. Therefore, if not specified correctly, the wrong type of surface treatment will have a negative impact on the overall PCBA manufacturing efficiency. This is an important detail that is often missed when asking for a quote.

3, screen printing

Another detail that is often overlooked is screen printing. As with the solder choke layer, it's not enough to click "yes" in the silkscreen options. You should also answer questions about whether you want double sides and what colors you want.

Four, impedance details: the controlled impedance requirements of the circuit board determines the selection of various parameters. Therefore, if it is not provided, the quotation will be delayed, because the quotation engineer needs to judge by guessing or multiple evidences.

Five, layer details: layer number, layer sequence, thickness of each layer, the total thickness of the layer, etc., are about the details of the layer, not to be missed.

Six, open hole: any opening on the plate that is not mechanically drilled is called open hole. The size and location of the cut is also part of the information provided when requesting a quote.

As a smt patch factory, we would like to tell all customers that any business communication should be based on equal communication and good coordination between both sides. Both sides have the responsibility and obligation to support each other's orderly work and ensure the formal and lawful rights and interests of both sides.