Affected by the rising demand of high-end equipment market, labor cost and national policy support, the development prospect of the domestic industrial control equipment industry is good, and the upstream printed circuit board industry forms a stable market demand. According to Prismark statistics and forecasts, the global industrial control industry demand for PCB board scale is about $2.64 billion in 2016, and is expected to reach $3.2 billion in 2021, with a compound annual growth rate of about 4.3% in the next five years. Modern medical device products gradually show the characteristics of digitalization and computerization. Medical electronics are widely used in medical device products, such as electronic sphygmomanometer, electronic thermometer, blood glucose meter, diabetes treatment instrument, etc., as well as medical device products commonly used in hospitals, such as ultrasonic instrument (color ultrasound, B ultrasound, etc.), CT, X-ray machine, electrocardiogram machine, etc.

Automotive electronics is the general term of car body automotive electronics and automotive electronic control device, is composed of sensors, microprocessors, actuators, electronic components and other electronic control system. With the increasing demand for overall safety, comfort and entertainment of automobiles, electronization, informatization, networking and intelligentization have become the development direction of automobile technology.

At the same time, the rapid development of new energy vehicles, safe driving assistance and driverless technology has enabled more high-end electronic communication technologies to be applied in automobiles, and the proportion of automotive electronic system in the vehicle cost has been increasing. The trend of automobile electronization is confirmed, and the trillion-level market promotes the stable growth of automobile PCB. China will gradually become a major market for automobile electronization.

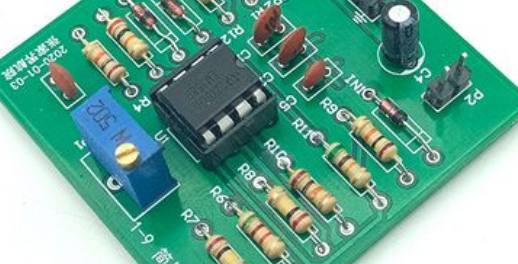

With the rapid development of automotive electronics, the high reliability requirements of automotive PCB products are becoming stricter. Automotive PCB requirements working temperature must meet -40℃~85℃, PCB generally choose FR4 (fire resistant material grade, mainly for glass cloth substrate), thickness in 1.0~1.6mm. According to the China Industry Development Research Network, the cost of automotive electronics accounts for 28 percent of mid-to-high-end cars, 47 percent of hybrid cars and 65 percent of pure electric cars. The proportion of automotive electronics in the overall manufacturing cost is increasing, driving the demand area of automotive PCB will increase at the same time. Because the working environment of automobile is very complex, the reliability of PCB is very high. Comparatively speaking, automotive PCB needs to go through a series of tests, the entry threshold is high, and it needs to go through a long period of certification. In order to save costs, manufacturers generally do not easily change the certified supplier. In addition, due to the unique recall system of the automobile industry, smaller manufacturers are excluded, so automotive PCB is mostly provided by large-scale manufacturers, and the order is relatively stable.

Domestic PCB development trend outlook: Increasing industry concentration

In terms of product type, due to the overall development of PCB industry to high density, high precision, high performance direction, products continue to reduce the size, light weight and performance upgrade, in order to adapt to the needs of different downstream application fields, more precise HDI board and IC packaging board investment will continue to increase. At present, the state attaches more and more importance to environmental protection. Since 2018, the central government has implemented the Environmental Protection Tax Law of the People's Republic of China, which forces the transformation and upgrading of enterprises with high pollution and high energy consumption through the tax mechanism, and restricts the investment in low-end PCB products with less than 4 layers, making the low-end PCB products with low cost and low investment, such as single and dual panels, gradually withdraw from the market. In addition, with the promotion of 5G and new energy vehicles, the application of multilayer panels in high-speed, high-frequency and high-heat fields will also continue to expand. PCB products in quality and quantity, continue to tilt to the high-tech field, enterprises in technology research and development investment will continue to increase.

In terms of industry scale and concentration, PCB industry scale will continue to expand, more and more enterprises try to raise funds to expand production through market means, forming scale advantage. Some small and medium-sized enterprises that lag behind will gradually withdraw from the market, and the advantage of production capacity will be concentrated in leading enterprises.

In terms of industrial layout, PCB enterprises are mainly distributed in the Pearl River Delta, Yangtze River Delta and Bohai Rim region. In the early stage, PCB production capacity was concentrated in Bohai Bay area, Taiwan enterprises concentrated in Yangtze River Delta, and a large number of local excellent electronic enterprises and medium and high-end PCB enterprises concentrated in Pearl River Delta. The output value of PCB in the Yangtze River Delta and Pearl River Delta accounts for about 90% of the total output value in mainland China. In recent years, due to the rising labor cost, some PCB enterprises have moved their production capacity from the Pearl River Delta and Yangtze River Delta to the Midwest cities with better basic conditions. The Pearl River Delta and the Yangtze River Delta, by taking advantage of their advantages in talent, economy and industrial chain, continue to develop towards high-end products and high value-added products.