I. Positioning of PCBA assembly plant

1. The assembly plant is positioned to provide the best products and services based on customer requirements.

2. The assembly plant shall accurately position, analyze the needs of customers, and provide the best quality products and services to meet the needs of customers.

3. Assembly plants should grasp customer needs, determine the target market, carry out targeted marketing, and constantly improve customer satisfaction.

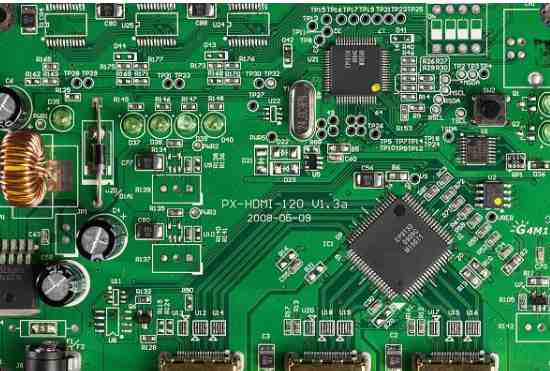

PCBA assembly plant

Ii. Operation of PCBA assembly plant

1. The assembly plant shall establish an effective management system to ensure the quality of production and operation and improve the economic benefits of the assembly plant.

2. The assembly plant shall establish an effective technical system to ensure the assembly quality, and constantly improve and update the technology to meet the requirements of customers.

3. The assembly plant shall establish an effective organizational structure, refine the organizational management, and improve the operation efficiency of the assembly plant.

3. Quality control of PCBA assembly plant

1. The assembly plant shall establish strict quality inspection standards to ensure that the quality of products meets customer requirements, so as to ensure customer satisfaction.

2. The assembly plant shall establish an effective quality assurance system and conduct regular product quality inspection to ensure the quality stability of each product and fundamentally improve customer satisfaction.

3. The assembly plant shall ensure the reliability of the supply chain to ensure the quality of every detail, such as the quality of materials used, the process flow and the precision of testing equipment.

4. Assembly plants should pay attention to customer feedback, track product quality in time, discover and solve problems in time, so as to ensure customer satisfaction.

5. The assembly plant needs to establish perfect quality files and quality records, so as to discover and solve problems timely and ensure the stability of product quality.

6. The assembly plant shall establish an effective quality assurance mechanism to ensure that the product quality meets the expected requirements, so as to improve customer satisfaction.

2. These designs are prepared to ensure the quality of PCBA proofing

PCBA proofing is a proofing technique carried out after PCB board design, which usually requires a certain design preparation, including material selection, PCB design, PCB size, PCB thickness, PCB layers, PCB board materials, PCB surface treatment, etc. These design preparations need to take into account the functional requirements of the PCB board, as well as the reliability requirements of the PCB board, to ensure the quality of the proofing.

PCBA proofing

welding

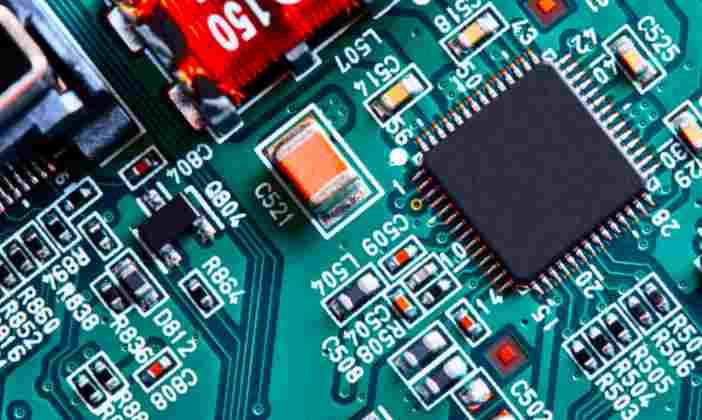

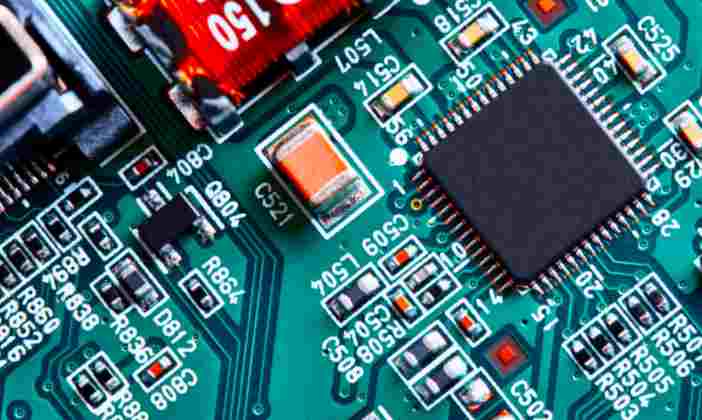

In the process of PCBA proofing, it is necessary to go through the PCBA welding process. Generally, automatic welding machine is used for welding. In this process, the shape of the pad on the PCB board, the size of the pad and the treatment of solder joints should be taken into account to ensure the quality of PCBA welding.

detection

In the process of PCBA proofing, it is necessary to test the PCBA circuit board to ensure the connection performance of the PCB board and the functional performance of the circuit. Generally, X-Ray detector and circuit detector are used for testing.

encapsulation

In the process of PCBA proofing, PCBA packaging is required. Generally, plastic packaging, metal packaging and thermal packaging are used for packaging. In this process, the selection of PCB board packaging materials, PCB board packaging size and PCB board packaging thickness should be taken into account to ensure the quality of packaging.

test

In the process of PCBA proofing, it is necessary to test the PCBA circuit board to ensure the functional reliability of the PCBA circuit board. Generally, tools such as tester and test program are used for testing to ensure the quality of PCBA proofing.

packing

In the process of PCBA proofing, PCBA packaging is required. Generally, plastic bags, cartons, cartons and other materials are used for packaging. In this process, packaging materials, packaging size and packaging thickness should be taken into account to ensure the quality of PCBA packaging.