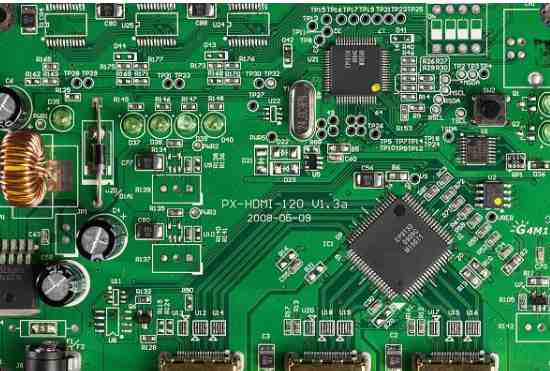

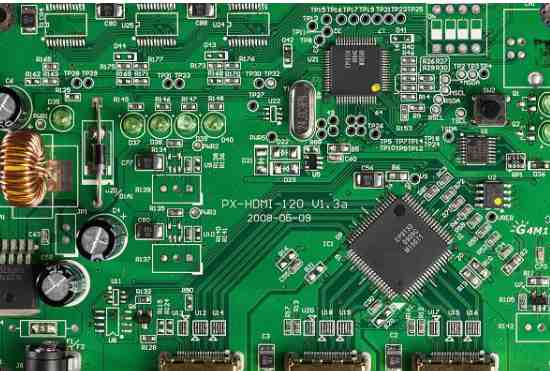

PCBA OEM is a Printed Circuit Board (PCB) processing service, is a printed circuit board assembly service. It can help customers achieve faster, more efficient product manufacturing, saving customers time and money. This paper will introduce the function, process, and related matters for attention of PCBA OEM.

I. Function

PCBA OEM has three main functions:

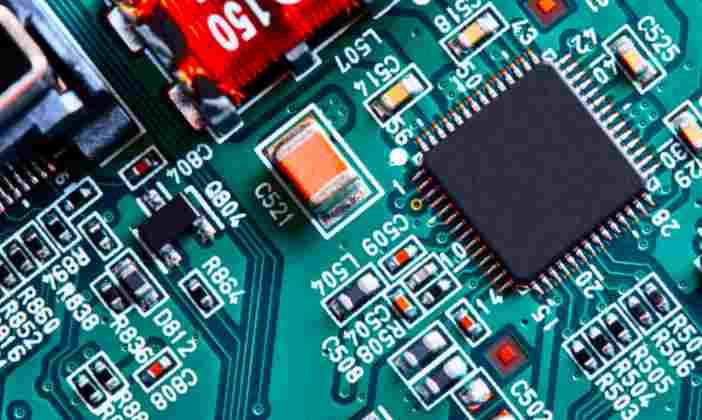

1. Assemble chips: PCBA foundry installs computer chips or components on the printed board to complete the assembly of the printed board.

2. Processing: PCBA OEM can also be used for the processing of printed boards, including polishing, metal etching, heat treatment, etc.

3. Testing: PCBA OEM can also be used for PCB board testing, to ensure that the assembled chips and components can work normally.

Ii. Process

The process of PCBA OEM can be divided into several steps:

1. Design: The first step of PCBA OEM is design, including the design of PCB board, chip, component and other related parts.

2. Plate making: In this step, PCBA works on behalf of manufacturing and materials to make the designed parts into printed boards.

3. Assembly: Assembly is the most important step in PCBA manufacturing and material assembly. It installs chips and components on the printed board to complete the assembly of the PCB.

4. Testing: The final step is testing. PCBA OEM will test the assembled printed board to ensure that it works properly.

Three, precautions

PCBA's OEM service also has certain precautions:

1. Time: PCBA's OEM service requires customers to provide accurate schedule to ensure that the service can be completed on time.

2. Quotation: When choosing PCBA OEM service, the customer should inquire the quotation of the service provider to ensure that the quotation provided by the service provider is reasonable.

3. Quality: The quality of PCBA OEM service determines the performance of products, so the customer should ensure that the service quality provided by the service provider is qualified.

In short, PCBA OEM is an indispensable part of the PCB printed board processing process, it can help customers to achieve faster, more efficient product manufacturing. In order to obtain better service, customers must understand the role, process and precautions of PCBA OEM, and ensure that the quotation provided by the service provider is reasonable and the service quality is qualified.

2. What is the PCBA OEM expect? Introduction to the advantages of PCBA OEM

PCBA OEM has been the talk of the electronics industry, today we will talk about the PCBA OEM expected at the end of what is.

I. Definition of PCBA OEM

PCBA OEM refers to the assembly service of raw materials to meet the specific requirements of customers through assembly, welding and other technical means, including: PCB board manufacturing, SMT patches, DIP automatic welding, assembly, testing and a series of assembly services.

Ii. Definition of PCBA substitute

PCBA OEM refers to all kinds of electronic components used in PCBA OEM, such as chips, resistors, capacitors, inductors, memory, touch screen, interface modules, displays, etc., they are all raw materials required by PCBA OEM.

3. Advantages of PCBA OEM

(1) PCBA OEM can meet customers' diversified product needs. PCB board can be customized according to customers' specific requirements to make products more in line with customers' needs.

(2) PCBA OEM adopts advanced automation technology, which reduces the space of manual operation, greatly improves the production efficiency and reduces the cost.

(3) The products produced by PCBA OEM have good reliability, more stable and durable, which is conducive to the long-term use of customers.

To sum up, PCBA OEM refers to a variety of raw materials used in PCBA OEM, and it can customize PCB boardto meet the diversified product needs of customers, the use of advanced automation technology, improve production efficiency, and the product has good reliability. Therefore, PCBA OEM by many electronic industry attention and welcome.