Friends from the industry, good morning, I am a small editor of kingford PCBA processing factory. Today Xiaobian is here to share with friends in the industry is as PCBA processing manufacturers, when receiving customer enquiries need the relevant production materials. I believe that many friends who do PCBA processing will encounter this situation, some of them are not very professional purchasing send a picture of PCBA board or send a BOM and ask our manufacturer to quote. So next, Xiaobian is here and friends in the industry to talk about, PCBA processing generally need what rigid information.

In fact, for the network promotion of PCBA processing plant, it is the most critical to find customers matching our PCBA factory. There are several customer enquiries every day, but we should determine whether they are our potential high-quality customers according to the types of customers and the characteristics of products, combined with the company's own strength and the established policy of the annual business meeting.

Since its establishment in 2010, Dongguan Xinyi Electronics Co., Ltd. has 4 N+1 patch production lines, 3 automatic insert machines, 4 DIP plug-in post welding production lines, 6 ASM530/520 bonding machines and 3 ASS finished product assembly lines. In June 2021, it opened a branch factory in Shiyan, Shenzhen. Add 2 N+1 Yamaha patch production lines and 2 plug-in post welding production lines. Adopt ISO9001, IATF16949 and ISO13485 quality system, lead-free environmental protection process, although not the leader in the industry, but compared with the general factory is a small scale, the system is relatively perfect, to deal with the customer certification is completely no problem, just because our patch production line uses N+1 equipment online, Therefore, the low output value brought by small-batch customers cannot be matched. Therefore, as the front end of marketing, it is very important to find the right customers.

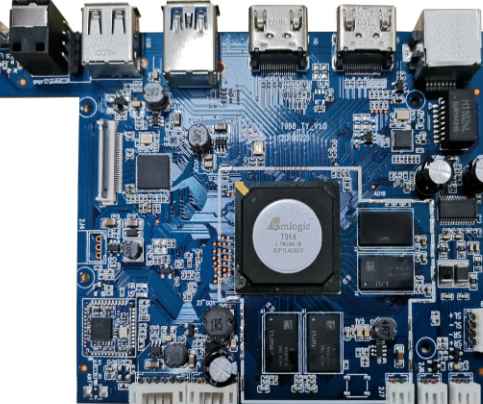

When customers are looking for PCBA processing suppliers, they will get to know each other in the early stage. Our business will visit them to know whether their products are cutting-edge products and the comprehensive strength of their customers. After the first conversation, we will confirm that they meet our target customers. Confirm the cooperation intention of both parties, the customer will leave the physical sample, provide BOM list, GEB file and test file, and our company's marketing engineering will evaluate the quotation according to MOQ. In the quotation, besides referring to the number of electronic materials in BOM list and the physical sample, there are also shaping of electronic components, steel mesh, through oven fixture, fixture and test fixture. Labor costs such as testing, burning, quality inspection, packaging and shipping. The absence of a certain information will increase the communication cost and delay the delivery date, which will have a great impact on the timely launch of the product.

Gerber file includes (Pad layer, solder resistance layer, screen printing layer, steel mesh layer), which is highly authoritative data in the patch processing, because the subsequent PCBA quotation and processing fee quotation need Gerber data for reference. Patch processing must use the steel mesh, open the steel mesh also need to know the information of the steel mesh layer.

BOM list is also called component list. Simply speaking, it refers to the materials contained on PCBA board. The corresponding materials are different in price due to their different brands, models and specifications.

Coordinate file, generally can be exported from the Gerber file, it is mainly the coordinates of the components for positioning, when the project to do the program needs to use this file.

The physical sample is mainly to check whether there is a process of shaping electronic components before the patch and plug-in, as well as the process and quality requirements of the product stealth, so as to provide accurate quotation and ensure quality.

Process guidance documents, as the designer's control of the process in the process of solution processing, generally exist as some guidance documents for manufacturers. Include special requirements and special design points.

The test document, also known as the test specification, has the items and categories of the test, including the parameters and technical indicators of the test, and the on-site handling methods of the exceptions.

2. What is the PCBA OEM expect? Introduction to the advantages of PCBA OEM

Today we are going to talk about what the PCBA foundry is like.

I. Definition of PCBA OEM

PCBA OEM refers to the assembly service of raw materials to meet the specific requirements of customers through assembly, welding and other technical means, including: PCB board manufacturing, SMT patches, DIP automatic welding, assembly, testing and a series of assembly services.

Ii. Definition of PCBA substitute

PCBA OEM refers to all kinds of electronic components used in PCBA OEM, such as chips, resistors, capacitors, inductors, memory, touch screen, interface modules, displays, etc., they are all raw materials required by PCBA OEM.

3. Advantages of PCBA OEM

(1) PCBA OEM can meet customers' diversified product needs. PCB board can be customized according to customers' specific requirements to make products more in line with customers' needs.

(2) PCBA OEM adopts advanced automation technology, which reduces the space of manual operation, greatly improves the production efficiency and reduces the cost.

(3) The products produced by PCBA OEM have good reliability, more stable and durable, which is conducive to the long-term use of customers

To sum up, PCBA OEM refers to a variety of raw materials used in PCBA OEM, and it can customize PCB board to meet the diversified product needs of customers, the use of advanced automation technology, improve production efficiency, and the product has good reliability. Therefore, PCBA OEM by many electronic industry attention and welcome.