First, SMT technical advantages

1, cost saving: SMT patch technology can greatly save costs, its circuit board patch technology than the traditional welding technology has a higher cost saving rate, can greatly reduce the cost;

2, improve efficiency: SMT technology can effectively improve the efficiency of production, its high degree of automation, can greatly improve the production efficiency and quality;

3, improve reliability: SMT technology has higher reliability than traditional welding technology, can provide higher quality electronic components, so as to improve the reliability of products.

Second, the application of SMT patch technology

1. Chip patch: SMT patch technology can greatly improve the packaging efficiency of chips, thus improving the overall performance and reliability of electronic products;

2, film patch: SMT patch technology can realize the film patch, so as to improve the overall assembly quality of electronic products;

3, IC patch: SMT patch technology can realize the IC patch, so as to make the structure of electronic products more compact, reduce costs, improve reliability.

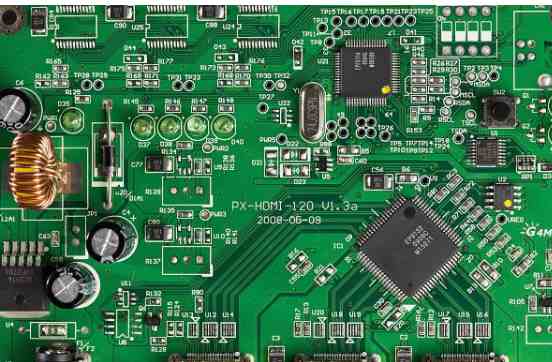

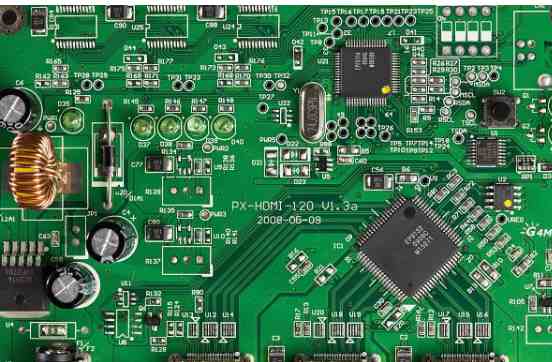

SMT patch

Iii. Operation process of SMT patch technology

1. Preparatory work: Before SMT technical operation, all tools and materials, including chip, PCB board, SMT machine, fixture, etc., shall be prepared;

2. Chip patch: Put the prepared chip into the patch fixture, and then use the chip patch machine to patch the chip onto the PCB board;

3. Completion of welding: After the chip is placed on the PCB board, the welding machine is used to complete the welding of the chip, so as to complete the operation of the entire SMT patch technology.

Four, SMT technology classification

1. Disposable patch: Disposable patch technology is a fast SMT patch technology, which can effectively improve the packaging efficiency of the chip;

2, multiple patch: Multiple patch technology is a more complex SMT technology, can meet the packaging needs of more complex electronic products;

3. Hybrid patch: Hybrid patch technology is a combination of disposable patch and multiple patch technology, which can effectively meet the packaging requirements of complex electronic products.

V. Points for attention of SMT patch technology

1. Operation process: When using SMT technology for packaging operation, the operation process must be followed to ensure the accuracy of the operation;

2. SMT fixture: When packaging with SMT technology, correct fixture must be used to ensure the accuracy of chip placement;

3. Welding quality: Correct welding machine must be used to ensure the quality of welding when using SMT technology for packaging operation.

Vi. Development of SMT patch technology

1. Chip development: With the continuous development of chip technology, SMT technology is constantly updated, so as to provide more updated technology for chip packaging;

2. Automation level: With the continuous improvement of automation level, SMT technology is also continuously improved, so as to realize efficient packaging of electronic components;

3. SMT equipment: With the continuous update of new SMT equipment, SMT technology is also constantly updated, so as to realize more efficient packaging of electronic components.

2. What kinds of products does the patch factory have? What equipment does the patch factory make?

1. Product categories

The product categories of the patch factory are diverse, the common product categories are IC chip packaging, capacitance packaging, resistance packaging, magnetic bead packaging, inductance packaging, crystal packaging and so on. Each product category has different packaging forms, for example, IC chip packaging has DIP, SOIC, SSOP, QFP and other packaging forms, capacitor packaging has SMD capacitor, crystal capacitor, capacitor block and other packaging forms, inductance packaging has SMD inductance, inductance block and other packaging forms, magnetic bead packaging has SMD magnetic bead, magnetic bead block and other packaging forms, Crystal packaging has SMD crystal, crystal block and other packaging forms.

2. Production equipment

The production equipment of the patch plant mainly includes the patch machine, testing equipment, testing equipment, cleaning equipment and so on. SMT machine is mainly used for patch processing, such as the higher the accuracy of the patch machine, the higher the efficiency of the patch, testing equipment for testing the quality of the patch, such as X-ray detector, temperature detector, testing equipment for testing the performance of the product, such as radio frequency tester, electrical tester, cleaning equipment for cleaning products, such as ultrasonic cleaning machine.

3. Production process

The production process of the patch plant mainly includes raw material preparation, patch processing, detection, testing, cleaning, packaging and other steps. Preparation of raw materials: prepare IC chip, capacitor, inductor, magnetic bead and other components, and prepare PCB board; Patch processing: patch the components to the PCB board in accordance with the designed package form; Detection: Use X-ray detector to detect whether the patch has defects; Test: Use radio frequency tester to test the performance of the product; Cleaning: Use ultrasonic cleaning machine to clean products; Packaging: The product will be packaged as required.

Fourth, product quality

The quality of products is the key to the production of the SMT plant. The quality of products directly affects the evaluation of customers on the plant. Therefore, the plant should pay attention to the management of product quality. The method of quality management can be ISO9000 system, regular testing of products, to ensure the quality of products; At the same time, quality assurance measures should be adopted, such as procurement quality management, production process management, testing and measurement management, quality improvement management, etc., to ensure product quality.

5. Production management

The production management of the patch plant mainly includes plan management, schedule management, report management, procurement management, inventory management, etc. Plan management: make production plan and ensure the production progress according to the plan; Schedule management: control the production schedule, timely control the production situation; Report management: statistical production data, generate production reports; Purchasing management: make purchasing plan to ensure the continuous supply of raw materials; Inventory management: monitor product inventory and replenish raw materials in time.

Vi. Customer Service

Customer service is the key to keep long-term cooperative relationship with customers and improve customer satisfaction. The patch factory shall establish a perfect customer service system and provide one-stop service, including pre-sale service, in-sale service and after-sale service. Pre-sale service: provide product consultation, quotation and other services; In-sale service: provide production schedule update, quality control and other services; After-sales service: Provide after-sales support, after-sales service and other services.