What are the reasons for FPC hot press degumming?

FPC hot press is the primary equipment to produce plywood, and production technology will directly affect the quality of plywood. But in the process of hot press operation, it is inevitable that there will be some questions, such as low bonding strength or degumming appearance. So today we will analyze the reasons for this question and how to deal with it.

Reason: 1. Maybe the quality of the glue is too poor. 2. It may be that the amount of glue is not enough or the glue is not uniform. 3. The pressure given by the hot press may not be too low temperature, or the hot pressing time is too short. 4. The burr grooves of the veneer are too deep, perhaps because the water content is too high. 5. Aging time is too long, resulting in dry glue. Perhaps aging time is too short, so that it does not form a continuous film.

FPC hot press degumming method

Treatment methods: carefully check the quality of glue liquid, purchase excellent glue liquid; Pay attention to the time of glue evenly moderate; Appropriate forward temperature and hot press pressure to extend hot pressing time; Carefully control the aging time; The spinning quality of the forward veneer; Maintain boards to ensure that the water content of boards is within the specified plan. Secondly, is the surface of the indentation. The reason for this appearance may indicate that the surface of the pad is uneven, and the hot press pad should be replaced in time; There may also be rubber blocks or debris on the surface of the pad, just clean it up. When the hot press is operating, any doubt will affect the quality of plywood, so when there is doubt, it is necessary to make timely differentiation and accurate processing.

FPC hot press mainly welding electronic products such as products, but the specific also ask professional manufacturers, we Yalan electronic main production of hot press, pulse hot press, constant temperature hot press, as long as you need, we can customize.

First, the internal parts of the mobile phone, mobile phone must be no stranger to us, mobile phone is now a basic necessity, even some people more than one mobile phone. We use mobile phones every day, must not know that mobile phones will also use pulse hot pressing welding machine this thing, because pulse hot pressing welding machine sounds like a big machine, feel the working policy is also some very endless parts, but small mobile phones often use pulse hot pressing welding machine. Mobile phone to use pulse hot press welding machine is usually for mobile phone screen or camera FPC welding to PCB.

2. Production side of the rear end of the touch screen. Now there are many touch screen products, touch screen mobile phones, touch screen computers and so on, and some resistance touch screen and capacitive touch screen binding technology is usually widely used in pulse hot pressing welding machine.

Three, all kinds of electronic goods. From the above two applications we can also make a brief summary, usually flash goods will be used in the pulse hot pressing welding machine. With the increasing size of various flash electronic goods, we can also further infer that the use of pulse hot pressing welding machine will be more and more extensive. So we can guess that the market of pulse hot pressing welding machine will be more and more broad. So suppose you want to purchase pulse hot pressing welding machine, in order not to dizzying on the vast market, we should know how to distinguish the quality of pulse hot pressing welding machine, so talent to buy good goods.

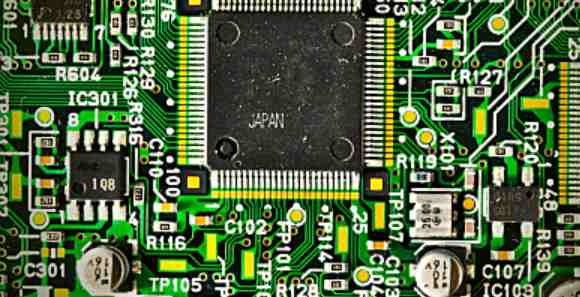

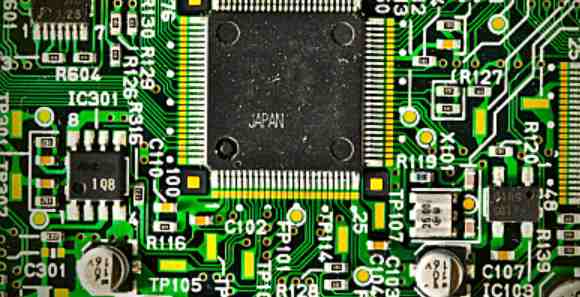

Impedance circuit board Analysis of PCB circuit board impedance reasons

pcb circuit board impedance refers to the resistance and reactance of the parameter, the alternating current plays an obstruction role. Impedance processing is essential in pcb circuit board production. So do you know why PCB circuit boards do impedance?

1, PCB circuit board bottom to consider plug installation of electronic components, plug into the electrical performance and signal transmission performance and other issues, so it will require impedance as low as possible, resistivity below 1×10-6 per square centimeter.

2, PCB circuit board in the production process to experience copper sinking, electroplating tin (or electroless plating, or hot spray tin), solder joints and other processes, and the materials used in these links must ensure the resistivity bottom, in order to ensure that the overall impedance of the circuit board is low to meet the product quality requirements, can operate normally.

3, the tin plating of PCB circuit board is the most prone to problems in the production of the whole circuit board, is the key link affecting the impedance. The biggest defect of electroless tin layer is easy to change color (easy oxidation or delixing), poor brazing, which will lead to the welding of the circuit board, high impedance leading to poor conductivity or instability of the whole board performance.

4, PCB circuit board in the conductor will have a variety of signal transmission, when to improve its transmission rate and must improve its frequency, the line itself if the etching, laminated thickness, wire width and other factors are different, will cause impedance value change, so that the signal distortion, resulting in circuit board performance decline, so it is necessary to control the impedance value in a certain range.