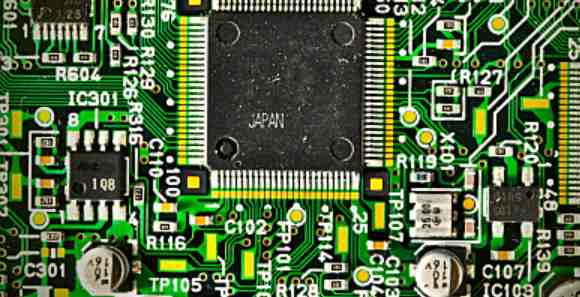

Electrolytic capacitor is a kind of capacitor, the metal foil is positive electrode (aluminum or tantalum), and the positive electrode close to the metal oxide film (alumina or tantalum pentoxide) is the dielectric, the cathode is composed of conductive materials, electrolytes (electrolytes can be liquid or solid) and other materials (PCB circuit board,FPC circuit board), because electrolyte is the main part of the cathode, Hence the name electrolytic capacitor. At the same time, the positive and negative electrolytic capacitors can not be connected wrong. Aluminum electrolytic capacitors can be divided into four categories: linear aluminum electrolytic capacitors; Horn type aluminum electrolytic capacitor; Bolt-type aluminum electrolytic capacitor; Solid state aluminum electrolytic capacitor.

Electrolytic capacitance action

1. Filtering effect: in the power supply circuit, the rectifier circuit will change AC into pulsating DC, and after the rectifier circuit is connected to a large capacity electrolytic capacitor, using its charge-discharge characteristics (energy storage), the pulsating DC voltage after rectification into a relatively stable DC voltage. In practice, in order to prevent the supply voltage of each part of the PCB manufacturing circuit from changing due to the load, the output end of the power supply and the input end of the load are generally connected with dozens to hundreds of micromethod electrolytic capacitors. Because large capacity electrolytic capacitors generally have a certain inductance, high frequency and pulse interference signals can not effectively filter, so in parallel at both ends of a capacity of 0.001--0.lpF capacitor, in order to filter high frequency and pulse interference.

2, coupling effect: in the transmission and amplification of low-frequency signals, in order to prevent the static operating points of the circuit before and after the influence of each other, capacitor coupling is often used. In order to prevent the signal rhyme low frequency component loss is too large, generally the total use of large capacity electrolytic capacitors.

Precautions for using electrolytic capacitors

1, electrolytic capacitor because of positive and negative polarity, so in the circuit can not be used in reverse connection. In the power supply circuit, the positive electrode of the electrolytic capacitor is connected to the output terminal of the power supply when the positive voltage is output, and the negative electrode is grounded. When the output voltage is negative, the negative terminal is connected to the output terminal and the positive terminal is grounded.

When the polarity of the filter capacitor in the power supply circuit is reversed, the filter effect of the capacitor is greatly reduced. On the one hand, the output voltage of the power supply fluctuates, and on the other hand, the electrolytic capacitor, which is equivalent to a resistance, heats up because of the reverse current. When the reverse voltage exceeds a certain value (metal core board), the reverse leakage resistance of the capacitor will become very small, so that the power working soon, the capacitor can be caused by overheating and cracking damage.

2. The voltage added to both ends of the electrolytic capacitor cannot exceed its allowable working voltage. In the design of the actual circuit, a certain margin should be left according to the specific situation. At this time, the selection of electrolytic capacitor with voltage resistance of 25V can generally meet the requirements. However, if the AC power supply voltage fluctuation is large and may rise to more than 250V, it is best to choose the electrolytic capacitor with a voltage of more than 30V.

3, the electrolytic capacitor in the circuit should not be close to the high-power heating element, in order to prevent due to heat and accelerate the electrolyte dry.

4. For the filtering of positive and negative polarity signals, two electrolytic capacitors can be adopted in series with the same polarity as a non-polar capacitor.

5, capacitor housing, auxiliary leading terminal and positive, negative and circuit board must be completely isolated.

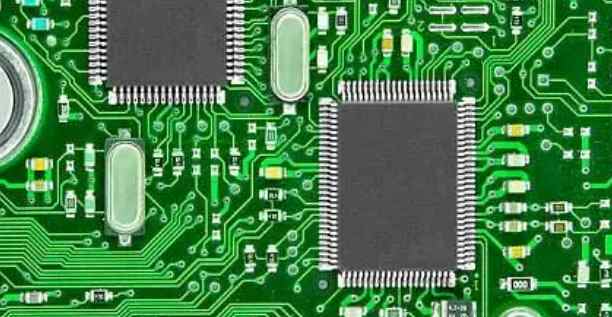

PCB copy board (circuit board copy board) copy board analysis panoramic camera parking technology

As cameras based on a 360-degree panoramic system are increasingly an optional feature of cars, the technology will do as much as it can for self-parking vehicles that solve the hassle of finding a spot or plugging in.

The system uses the rear view camera of the 360-degree panoramic system to prevent collisions during reversing. "Fisheye cameras with 360-degree panoramic systems are ideal for autonomous parking because they are able to 'see' the full picture around the car," he said. "For example, their wide aperture angles even allow viewing of parking Spaces with corners. In addition, the camera can detect the white parking space boundary line, which is not possible with traditional ultrasonic sensors."

The 360-degree panoramic system has the potential to expand

The driver can change the recommended parking position by moving the outline of the car in any direction on the touch screen. This option allows the driver to respond to specific situations that are difficult to interpret even with high-performance object-recognition systems (such as delivery vehicles parked in front or behind the vehicle and requiring more maneuvering space than a car).

In the future, autonomous parking based on 360-degree cameras will also allow drivers to park from outside the vehicle, or remotely initiate parking operations. "In Remote Parking, the driver uses a touch screen to select the parking space and activate Remote mode, then leaves the car and uses the smartphone app to initiate and observe the automatic parking operation."

As the system is further refined, the current progress will evolve into a scalable, mass-production-capable system that can provide one or more ancillary functions to the overall on-board network. These features, based on a 360-degree panoramic system, will include intersection assist and reverse assist with automatic braking.