Electronic products pursue miniaturization, the past use of perforated plug-in components can not be reduced. Electronic technology products are more functional, using integrated system circuits (ics) without perforated components, especially for large-scale, highly integrated ics, have to choose to use different surface patch components. smt plant mass production, production automation, factory with low cost high yield, high quality products can meet the needs of enterprise customers, improve the competitiveness of the Chinese market economy, the development of electronic components, integrated circuit (ic) development, multi-semiconductor material applications.

For the fine processing industry, kingford believes that in the production process, there must be a lot of attention to detail and some small skills in the processing of knowledge.

1. In the preheating zone and cooling zone of smt processing, due to improper setting of reflux section, micro-cracks occur in parts;

Two, chip repair tools: electric soldering iron, hot air workbench, tin gun, tweezers;

Three, high speed SMT machine can be installed resistor, capacitor, integrated circuit and transistor;

Four, the cycle time of high-speed SMT machine and ordinary SMT machine should be balanced as far as possible;

Five, the definition of quality is the first time to do well;

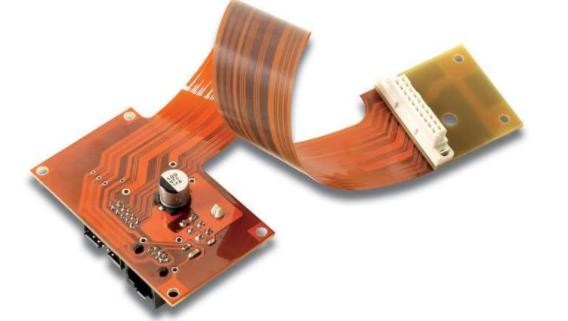

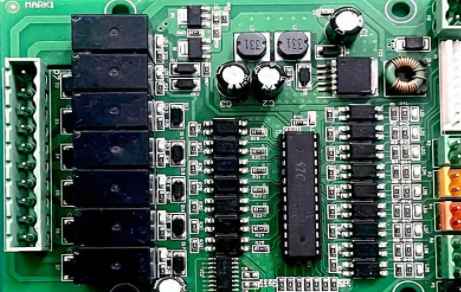

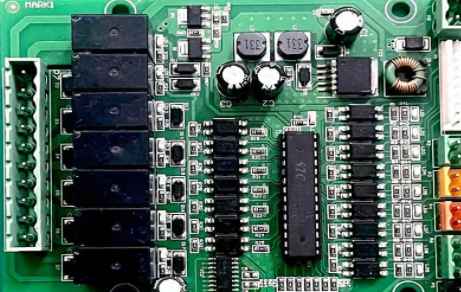

2. The difference between PCB and PCBA

kingford has been developing in the SMT field for more than 20 years as a SMT patch factory. Now I will explain to you what PCB is. What is PCBA?

What is a PCB?

Pcb = printed circuit board, also known as printed circuit board, is an important electronic component, is the basis of supporting electronic components.

The carrier on which electrical equipment is connected. It's made by electronic printing, so it's called a "printed" circuit board.

What is PCBA?

Pcba = PCB assembly. The development of various technology enterprises electronic devices can be assembled on the circuit board through the analysis of the surface packaging process. Next comes the box assembly, which assembles the pcb with the case.

And then we put it together and we make a finished product. That is to say, the printed circuit board after the blank patch, and then immersed in the plug-in the whole design process, referred to as pcba. This is a common writing method in China, while in Europe and the United States is the standard writing method, is PCBA, is added oblique point. PCBA, which is the PCB we put on ourselves.

Pcb refers to the circuit board, and pcba refers to the plug-in assembly of the circuit board, smt process. There's a finished board and there's a bare board.

The printed circuit board is made of epoxy glass resin composite material, the number of signal network layers can be divided into 4, 6 and 8 boards, the most common is 4.6 boards. The chip or other patch element is attached to the PCB.

Perhaps we can understand that PCBA is a finished product of an enterprise to manufacture circuit boards, which can only be counted as PCBA after all the processes of controlling circuit boards have been completed.

Printed Circuit Board.

That is to say, the printed circuit board after the blank patch, and then immersed in the plug-in the whole design process, referred to as pcba.

PCB (Printed Circuit Board, printed electronic circuit board) PCB is referred to as the Chinese printed design circuit board, known as the conductive pattern of the printed circuit is usually designed according to the insulation material by the printed line, printed components or a combination of the two. And on the insulating substrate to provide such a component between the development of the enterprise can be connected by electrical engineering equipment conductive graphics, known as the printed line.

3. Main cause of solder paste shortage in smt patch processing

1. Welding paste is not added in time when the printing press is working.

2. There is a problem with the quality of solder paste, which is mixed with foreign bodies.

3. Previously unused solder paste has expired and been reused.

4. The circuit board has management problems, and there are coverings on the pad, such as green oil (solder resistance) printed on the pad.

5. Clamp and fasten the circuit board in the printer.

6, the thickness of the net plate is not uniform.

7. There are pollutants on the screen or circuit board of the welding paste (such as pcb packaging, wiping paper, foreign bodies floating in the ambient air).

8, solder paste scraper is damaged, the screen is damaged.

9. Improper setting of pressure, Angle, speed and release speed of solder paste scraper.

10. Solder paste was accidentally knocked off because of human influence factors.