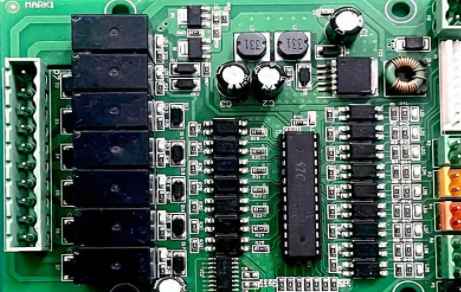

Circuit board is a very common and important part of us, it almost exists in every kind of electronic equipment around us, it is installed above a variety of components, through the wire and pad and metal holes for electrical line connection, in order to facilitate everyone to identify, pcba manufacturers also printed screen drawings on the above, so that it is easier to identify all kinds of components.

How to identify pcba OEM components

The components on PCB mainly fall into two categories, one is the through hole type, which is relatively large, and the board must be drilled to insert, the other is the surface patch type, this component does not need to drill, it is the use of steel die to put the semi-molten solder paste on the circuit board, and then paste the SMD components on it. It is welded to the circuit board by reflow soldering.

2. Understand the wires, holes and pads on the pcba patch board

The wire on the board made by pcba manufacturers is called copper film wire, which is used to connect the circuit board. Usually, the printed wire is the connection between two pads or through holes, and many pads are pins on the components. When two pads cannot be connected, they will be connected through jumper or through holes, also known as metallization holes. It is used to connect wires between different layers.

3. In the production of batch circuit boards, a layer of solder resistance will be laid on the board. The color of the solder resistance is usually green or brown, so the PCB processed by pcba is usually green or brown, which is actually the color of the solder resistance above it.

Usually in addition to the other places to be welded on the line, the solder resistance diagram is to add a layer of flux, so that it can be quickly welded, but also to prevent the overflow of solder caused by short circuit, for the welding pad to be coated with flux so as to facilitate welding.

2. What are the classifications of flexible printed boards

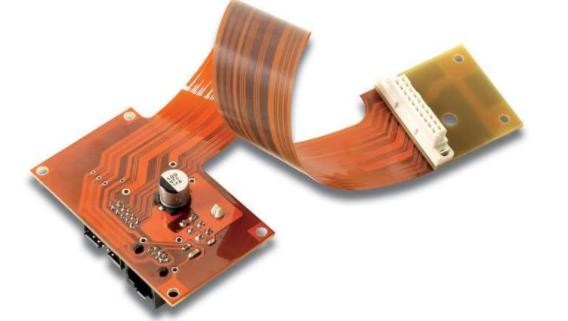

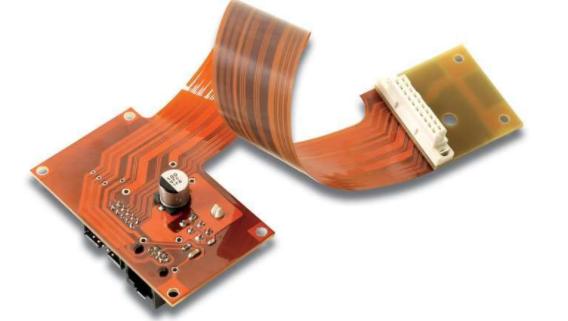

pcba manufacturers produce a variety of circuit boards have different roles, so what is the flexible circuit board in the manufacturing of pcba, flexible printed board commonly known as soft printed board (also known as flexible board), is in thin polymer substrate material etched out of copper circuit, or printed polymer thick film circuit. Flexible printed boards can also be strengthened locally through the use of reinforcing materials or lining for additional mechanical stability and increased support strength for component installation.

1. By structure and mechanical strength

Classification of flexible printed board according to its structure and mechanical strength, can be divided into flexible plate and rigid flexible combination of two categories, pcba processing flexible plate only flexible part; The rigid flexible joint plate consists of a rigid part and a flexible part. The surface of the flexible plate may have or may not have a covering layer.

2. According to the classification of conductive layers according to the number of conductive layers of the printed board can be divided into: single-sided flexible board with only one conductive layer, double-sided flexible board with conductive layer on both sides of the insulating substrate and multi-layer flexible board with three or more conductive layers.

3. pcba OEM is usually classified by the name of the film material in the substrate, such as polyester substrate type, Polyimide type, epoxy glass fiber sheet type, polyester epoxy glass fiber mixture type, polytetrafluoroethylene film type and aromatic polyamide type. pcba processing can also be divided into bonded and non-bonded forms according to the structure of the substrate. The adhesive form refers to the plate with adhesive adhesive as bonding laminate between copper foil and insulating substrate or covering layer; The non-bonding dosage form is a non-bonding agent between copper foil and insulating substrate, and directly laminated with insulating substrate board (also known as the two-layer substrate). Non-bonded flexible plate has good flexural performance and more dynamic bending times.

4. The common characteristics of flexible plates for IC device packaging are good heat resistance and high glass transition temperature of substrate. According to the installation form and structural characteristics of its devices, pcba patches include automatic installation of on-load chip (TAB) for coil flexible board, printed board for mounting chip on flexible film (COF), and printed board for chip level package (CSP) and multi-chip module (MCM). This kind of board is mostly made of modified epoxy glass fiber sheet as the base material.

In addition, pcba OEM manufacturersare classified according to whether the flexible plate part has reinforced layer or the wiring density and the purpose of use, no longer introduced one by one. No matter what kind of flexible plate, its common characteristic is the thin thickness of the printed board, with bending and bending properties.