This section describes common PCBA test fixtures

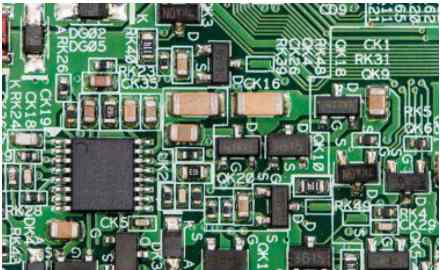

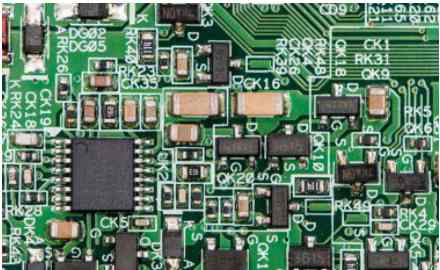

PCBA test is a very important link in the whole electronic manufacturing service, which can strictly control the delivery quality at the last stage, timely discover problems so as to adjust the early process such as SMT and DIP, optimize the process flow, and realize the quality control layer by layer with a test chain. Good PCBA test fixture can make the whole PCBA processing process twice the result with half the effort.

1. ICT test fixture

ICT test mainly includes circuit on-off, voltage and current values, wave curve, amplitude, noise, etc.

2. FCT test fixture https://www.kingfordpcb.com/yuan.php

https://www.kingfordpcb.com/yuan.php

FCT test requi This section describes common PCBA test fixtures

PCBA test is a very important link in the whole electronic manufacturing service, which can strictly control the delivery quality at the last stage, timely discover problems so as to adjust the early process such as SMT and DIP, optimize the process flow, and realize the quality control layer by layer with a test chain. Good PCBA test fixture can make the whole PCBA processing process twice the result with half the effort.

1. ICT test fixture

ICT test mainly includes circuit on-off, voltage and current values, wave curve, amplitude, noise, etc.

res IC program firing, simulation test of the function of the entire PCBA board, finding the problems in the hardware and software, and equipped with the necessary production fixture and test rack.

3. Fatigue test fixture

Fatigue test is mainly to sample PCBA board, and carry out high-frequency and long-term operation of functions to observe whether failure occurs and judge the probability of failure in test, so as to feedback the working performance of PCBA board in electronic products.

4. Environment test equipment

Testing in harsh environment mainly involves exposing PCBA board to the temperature, humidity, drop, splash and vibration of the limit value to obtain the test results of random samples, so as to infer the reliability of the whole batch of products of PCBA board.

5. Age the test device

The aging test is mainly to power on PCBA board and electronic products for a long time, keep them working and observe whether there is any failure. After aging test, electronic products can be batch.

1. Strength guaranteeSMT machines

▪SMT workshop: We have imported and several sets of optical inspection equipment, with a daily output of 4 million. Each process is equipped with QC personnel, who can keep an eye on product quality.

▪DIP production line: We have two wave-soldering machines, among which there are more than 10 old employees who have worked for more than three years. The skilled workers can weld all kinds of plug-in materials.

2. Quality assurance, cost-effective

▪ High-end equipment can stick precision shaped parts, BGA, QFN, 0201 materials. Can also template patch, loose material hand.

3. Rich experience in SMT and welding of electronic products, stable delivery

▪ Accumulated SMT SMT processing services for thousands of electronic enterprises, involving many kinds of automotive equipment and industrial control motherboard. The products are often exported to Europe and the United States, and the quality can be affirmed by new and old customers.

▪ On time delivery, normal 3-5 days after complete materials, small batch can also be expedited on the same day shipment.

4. Strong maintenance ability and perfect after-sales service

▪ Experienced maintenance engineers can repair all kinds of patch welding caused by bad products, to ensure the connection rate of each piece of circuit board.

PCBA test is a very important link in the whole electronic manufacturing service, which can strictly control the delivery quality at the last stage, timely discover problems so as to adjust the early process such as SMT and DIP, optimize the process flow, and realize the quality control layer by layer with a test chain. Good PCBA test fixture can make the whole PCBA processing process twice the result with half the effort.

1. ICT test fixture

ICT test mainly includes circuit on-off, voltage and current values, wave curve, amplitude, noise, etc.

2. FCT test fixture

FCT test requires IC program firing, simulation test of the function of the entire PCBA board, finding the problems in the hardware and software, and equipped with the necessary production fixture and test rack.

3. Fatigue test fixture

Fatigue test is mainly to sample PCBA board, and carry out high-frequency and long-term operation of functions to observe whether failure occurs and judge the probability of failure in test, so as to feedback the working performance of PCBA board in electronic products.

4. Environment test equipment

Testing in harsh environment mainly involves exposing PCBA board to the temperature, humidity, drop, splash and vibration of the limit value to obtain the test results of random samples, so as to infer the reliability of the whole batch of products of PCBA board.

5. Age the test device

The aging test is mainly to power on the PCBA board and electronic products for a long time, keep them working and observe whether any failure occurs. After aging test, electronic products can be sold in batches.

▪SMT workshop: We have imported SMT machines and several sets of optical inspection equipment, with a daily output of 4 million. Each process is equipped with QC personnel, who can keep an eye on product quality.

▪DIP production line: We have two wave-soldering machines, among which there are more than 10 old employees who have worked for more than three years. The skilled workers can weld all kinds of plug-in materials.

2. Quality assurance, cost-effective

▪ High-end equipment can stick precision shaped parts, BGA, QFN, 0201 materials. Can also template patch, loose material hand.

▪ Sample and size batch can be produced, proofing from 800 yuan, batch 0.008 yuan/point, no start-up fee.

3. Rich experience in SMT and welding of electronic products, stable delivery

▪ Accumulated SMT SMT processing services for thousands of electronic enterprises, involving many kinds of automotive equipment and industrial control motherboard. The products are often exported to Europe and the United States, and the quality can be affirmed by new and old customers.

Strong maintenance ability, perfect after-sales service

▪ Experienced maintenance engineers can repair all kinds of patch welding caused by bad products, to ensure the connection rate of each piece of circuit board.