Analysis of PCBA parts packaging technology

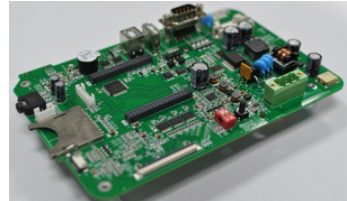

kinhford Electronic Technology Co., Ltd. today to introduce two PCBA packaging technology, respectively plug-in packaging technology and surface adhesive packaging technology.

1. Plug-in packaging technology

The technique of placing the parts on one side of the board and welding the pins on the other side is called plug-in packaging. Such parts take up a lot of space and require a hole to be drilled for each pin. So their joints actually take up space on both sides, and the solder joints are larger. Interfaces like wire sockets and things like that have to be pressure resistant, so they're usually THT packages. https://www.kingfordpcb.com/yuan.php?time=1685377305

https://www.kingfordpcb.com/yuan.php?time=1685377305

2. Surface adhesive packaging technology

Parts that use surface adhesive packaging are welded to the same side as the part. This technique does not weld holes in the PCB for each pin. SMT also has smaller parts than THT, and PCB boards using SMT technology are much more densely packed than PCB boards using THT parts. SMT packaging parts are also cheaper than THT's. So most of today's PCB is SMT, naturally not surprising.

Because the solder joints and parts are very small, it is very difficult to use manual welding. However, if you consider the current PCBA assembly is fully automatic, this problem will only occur when repairing parts.

The above is about the "PCBA parts packaging technology analysis" introduction, hope to have some help to you, more PCBA information please pay attention to the content of the site update! kinhford Electronic Technology Co., Ltd. is a professional PCBA processing enterprise, with fully automatic SMT production line and wave soldering, for you to open the whole production and quality testing process, find us, you belong to have your own electronic processing plant!