Introduction to Consumer Electronics PCBA

After the PCBA board completes the front-end welding process, it is still impossible to ensure that the PCBA board is intact. In order to ensure that the products shipped to customers are intact and improve customer satisfaction, it i

necessary to conduct necessary tests on the PCBA.

PCBA testing equipment mainly includes: solder paste thickness gauge, AOI optical detector, X-ray detector, ICT, FCT, aging test stand, etc.

1. Solder paste thickness gauge

The solder paste thickness gauge uses a laser to perform three-dimensional scanning to measure the thickness, area, and volume distribution of the solder paste on the circuit board, which can effectively control the quality of solder paste printing.

2. AOI Optical Detector

AOI automatically scans the PCB through the camera, collects images, and compares the tested solder joints with the qualified parameters in the database. After image processing, it can detect defects such as excess tin, less tin, continuous tin, warping, few pieces, and orientation.

3. X-ray detector

The X-ray detector uses low-energy X-rays to quickly detect the inspected object without damaging the inspected object. Usually used to check boards with BGA chips.

4. ICT

ICT is an automatic online tester, which has a wide range of applications and is easy to operate. The ICT automatic online detector is mainly for production process control, and can measure resistance, capacitance, inductance, and integrated circuits. It is especially effective for detecting open circuit, short circuit, component damage, etc., with accurate fault location and convenient maintenance.

5. FCT

The FCT function test is to point to the PCBA board to provide a simulated operating environment such as excitation and load, and can obtain various state parameters of the board to check whether the performance parameters of the board meet the designer's requirements.

6. Aging test frame

Aging test refers to the process of simulating various factors involved in the actual use conditions of the product to carry out corresponding condition strengthening experiments on the aging of the product. According to the PCBA board of electronic products, a long-term power-on test can be carried out to simulate customer use and conduct input/output tests to ensure that its performance meets market demand.

The above are important testing equipment in the PCBA processing process, and are necessary equipment to improve the quality of PCBA boards.

PCBA and PCB look very close, and they are often confused by laymen. In fact, the biggest difference between them is as follows:

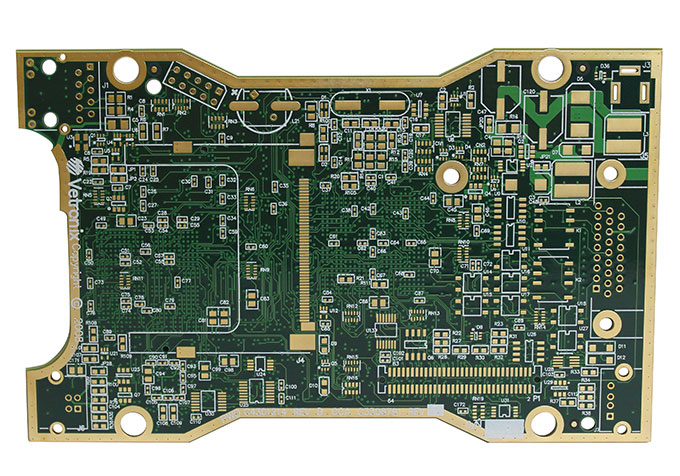

PCB

PCBAs

The first board with no components on it is the PCB, commonly known as an optical circuit board! The second board that has been processed and installed with components is called PCBA, commonly known as a circuit board. Our most common motherboards and sound cards are commonly known as PCBA in the industry. However, PCBA generally refers to the name used as an accessory during the production process.

[Function] The core part of all electronic products is composed of PCBA; the realization of all functions is inseparable from PCBA. Taking a desktop computer as an example, the units inside the chassis do not contain PCBA except for the heat dissipation part, and all the remaining functional units have PCBA. There are PCBA in the hard disk and power supply. There are display driver boards (PCBA) and LCD screens in the monitor other than the host computer, and there are also PCBA in the LCD screen. There is also a small PCBA inside the mouse, keyboard, and even the Bluetooth receiver of the wireless keyboard and mouse. Therefore, PCBA is the basic unit of all functions in the electronics industry.

【status】

PCBA is the most important part of all electronic product components, similar to the neural network of the human body. The brain of electronic products: the CPU is installed on the PCBA. The life, running speed, reliability and stability of general consumer electronics products have the most direct relationship with PCBA. Therefore, the quality of PCBA is also the most direct determiner of the overall quality of electronic products. Give you the best quality SMT, chip processing, embedded systems, electronic processing, embedded motherboards, PCBA labor and material services. PCBAWhat is PCBA? What is the function and status of PCBA?

What are PCBAs? This problem has always troubled newcomers in the production industry, and even many people can't tell the difference between PCBA and PCB. Today, Pater Technology will explain to you what PCBA is, including the difference between PCBA and PCB, as well as the function and status of PCBA.

【Glossary】

PCBA is the abbreviation of Printed Circuit Board + Assembly in English, that is to say, the empty PCB board passes through the SMT upper part, and then goes through the whole process of DIP plug-in, referred to as PCBA. This is a common way of writing in China, while the standard way of writing in Europe and America is PCBA 'A, with a slanted point. This is called the official idiom. When we communicate or promote with foreign customers, they often ask what PCBA means. However, more and more foreign friends have followed us to call it that.

【Exterior】

PCBA and PCB look very close, and they are often confused by laymen. In fact, the biggest difference between them is as follows:

PCB

PCBAs

The first board with no components on it is the PCB, commonly known as an optical circuit board! The second board that has been processed and installed with components is called PCBA, commonly known as a circuit board. Our most common motherboards and sound cards are commonly known as PCBA in the industry. However, PCBA generally refers to the name used as an accessory during the production process.

【Function】

The core part of all electronic products is composed of PCBA; the realization of all functions is inseparable from PCBA. Taking a desktop computer as an example, the units inside the chassis do not contain PCBA except for the heat dissipation part, and all the remaining functional units have PCBA. There are PCBA in the hard disk and power supply. There are display driver boards (PCBA) and LCD screens in the monitor other than the host computer, and there are also PCBA in the LCD screen. There is also a small PCBA inside the mouse, keyboard, and even the Bluetooth receiver of the wireless keyboard and mouse. Therefore, PCBA is the basic unit of all functions in the electronics industry.

【status】

PCBA is the most important part of all electronic product components, similar to the neural network of the human body. The brain of electronic products: the CPU is installed on the PCBA. The life, running speed, reliability and stability of general consumer electronics products have the most direct relationship with PCBA. Therefore, the quality of PCBA is also the most direct determiner of the overall quality of electronic products.