PCB circuit board reserved process edge benefits

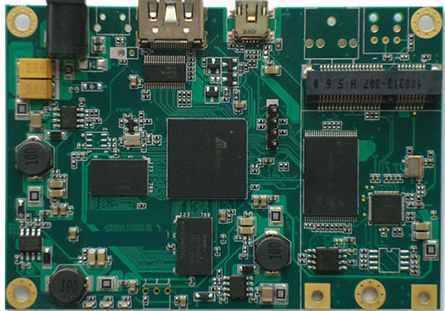

The main reason for the reserved process edge in PCB production is that the track of SMT mounter is used to clamp the circuit board and flow through the mounter. Therefore, when components too close to the track edge are absorbed by the mouthpiece of SMT mounter and pasted onto the circuit board, collision occurs and the production cannot be completed. Therefore, in the process of PCB assembling, in order to consider the subsequent patches and plug-ins, Usually you add a craft edge

The reserved process edge is the part added on both sides or four sides of PCB board to assist the patch plug-in to weld the missing board, which is mainly to assist production and does not belong to the PCB board. It can be removed after the PCBA manufacturing and production is completed.

PCB produPCB processction reserved process edge will consume more boards, increase the cost of PCB production, so in the design of edge, need to balance economy and manufacturability. For some special circuit boards, PCB boards with 2 or 4 process edges can be greatly simplified by means of PCB splicing. SMT processing in the design of the whole way, fully considering the track width, SMT placement machine for more than the width of 350 mm makeup need communication with SMT process engineer of supplier. 1. Customers place orders https://www.kingfordpcb.com/yuan.php?time=1685787379

https://www.kingfordpcb.com/yuan.php?time=1685787379

Customers place orders to PCBA processing plants according to their actual needs and put forward specific requirements. The processing plant will evaluate its capacity to see if it can fulfill the order. If the manufacturer is sure that they can complete the order within the expected time, then the two parties will negotiate to determine the production details.

2. Production materials provided by customers

After the customer decides to place an order, he provides a series of documents and lists to the PCBA processing plant, such as PCB electronic files, coordinate files and BOM lists required for production. 3. Purchase raw materials

PCBA processing plant purchases relevant raw materials from designated suppliers according to the documents provided by customers.

4. Incoming material inspection

Before PCBA processing, strict quality inspection is carried out for all raw materials to be used to ensure that they are qualified before being put into production. 5. PCBA production

In the process of PCBA processing, in order to ensure the quality of production, whether it is patch or welding production, the manufacturer needs to strictly control the furnace temperature. 6. PCBA test

PCBA processing plants deliver PCB boards to customers through rigorous testing. 7. Packaging after sale

After the PCBA processing is completed, the products are packaged and then handed over to the customer to complete the whole PCBA processing.

The above is about the "small fan PCBA processing process" introduction, I hope to have some help to you, more PCBA information please pay attention to the content of the site update! With fully automatic SMT production line and wave soldering, for you to open the whole production and quality testing process, find us, you belong to have your own electronic processing plant!

PCB production process edge flatness is also an important part of printed circuit board production. When removing PCB production process edges, it is necessary to ensure smooth process edges, especially for circuit boards with high assembly accuracy requirements. Any uneven rough edges will lead to offset installation holes and bring great trouble to subsequent PCBA assembly.