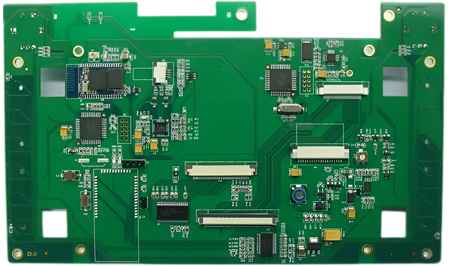

Select the aspects to be investigated in PCBA factory

When we select PCBA factories, it is unreasonable to judge the capacity of these factories only from the size of the factories. Let kinhford Electronic Technology Co., Ltd. introduce the aspects to be investigated in selecting PCBA factories:

1. Check whether the environmental impact assessment is qualified

Plants that do not meet environmental impact assessment requirements may be subject to random inspection, closure and rectification at any time.

2. View the quality management system certificate

ISO9001:2015 Quality Management system certificate, ISO13485 medical equipment component quality certificate, IATF16949 automotive electronic management certificate and so on.

3. Refer to raw material channel certificate

Ensure that all raw materials are sourced from official authentic sources to avoid mixing second-hand and defective materials into product production, which would bring great risk to end use.

4. Check the incoming inspection of IQC

Avoid batch composition errors, deviations, deformation or unqualified materials attached to the PCBA, which cannot be fully detected and covered in the test phase, bringing potential hidden dangers to the product, affecting stability, short service life and high after-effect sales pressure.

5. Look at ingredient storage

Effectively manage material storage to avoid transferring expired and invalid materials to the production line, which may lead to potential defects and risks in the product manufacturing process.

6. Esd prevention

Static electricity may penetrate the components on the PCBA at any time, resulting in a large number of repairs, rapid shortening of product life and other potential defects; All electronic component racks and PCBA product racks must be connected using separate static wires; All employees must wear rope static ring and static alarm; Daily electrostatic spot check records must be maintained.

7. See independent three anti paint treatment https://www.kingfordpcb.com/yuan.php

https://www.kingfordpcb.com/yuan.php

The external processing of three anti-paint is bound to cause the continuous transfer of PCBA, which is easy to cause collision, ESD electrostatic breakdown and other potential defects. PCBA factories need to be equipped with three anti-paint spraying production lines.

8. Look at engineering skills

The PCBA factory must have the ability to analyze and resolve defective PCBA boards, ensuring that root causes are found, fast shipments are made and customer engineers are freed up, rather than leaving all problems to the customer engineers.

9. Look at the level of site management

The operation site can reflect the overall execution capacity and level of the plant.

The above is about the "selection of PCBA factory need to investigate" introduction, hope to have some help to you, more PCBA information please pay attention to the content of the site update! kinhford Electronic Technology Co., Ltd. is a professional PCBA processing enterprise, with fully automatic SMT production line and wave soldering, for you to open the whole production and quality testing process, find us, you belong to have your own electronic processing plant!