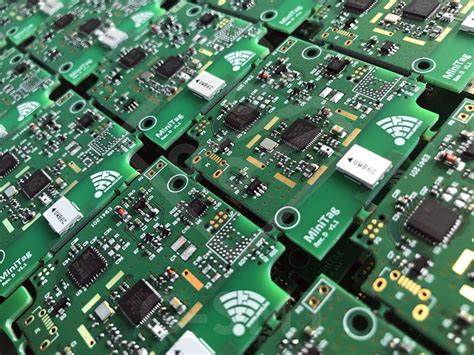

How to deal with this counterfeit SMT patch element type case?

According to an article published in Le Monde in 2016, the loss caused by counterfeiting of electronic components amounted to 7 order of the industry's total turnover of 30.9 billion euros in 2015, which is equivalent to 10 percent between 21 billion euros and 30 billion euros. From destroying computers to compromising the integrity of complex systems, which cost millions of euros, these illegal copies pose a significant risk to the entire industry. https://www.kingfordpcb.com/yuan.php

https://www.kingfordpcb.com/yuan.php

To combat this growing phenomenon, researchers and manufacturers must compete with traffickers to be creative and find new strategies to fight.The market for illegal copying is booming

At least one in two semiconductor firms has had to deal with counterfeits of its technology, and the number of copies in circulation is said to have quadrupled since 2009. The aircraft manufacturer has determined that counterfeit electronic circuits in its supply that appear to be real are in fact empty. In 2010, the U.S. military was the first to condemn the wave of illegal ingredients. Damaged components destroy infrared vision systems in helicopters, deicing systems in patrol aircraft or in-flight displays in transport aircraft.

Computer USB keys are something to talk about in 2016. The device is equipped with a DC-DC converter and capacitors responsible for connecting to send waste to the landfill, thus breaking the PC components. A Hong Kong company has copied the key and sold IT officially for use by IT security consultants.

Faulty electronic components are problematic for several obvious reasons:

Risk of injury and death in certain sectors (medical, military, automotive) Risk of fire in case of short circuitProperties of modified products

Huge costs and lost revenue to the industry

To replicate components, counterfeiters use a variety of techniques. They can try various kinds of espionage or reverse engineering to obtain blueprints of electronic components to discover their secrets.

Counterfeiting in the luxury industry is often talked about in the media, but all industries are affected by scale to a greater or lesser extent, and security risks fluctuate from product to product. Unlike the luxury industry, there is no right to fault in the military, aviation, automotive or medical industries.

There are many reasons for developing stolen electronic components: globalization has greatly reduced the cost of acquiring technology

The outsourcing of Asian production has facilitated technology transfer

Interoperability of operating systems in IT has enabled information to spread on a large scale

Freight giants have adapted their products to make shipping small packages affordable

Counterfeiting also comes from the production of electronic waste sent from developed countries to developing countries. Counterfeiters use this waste as raw material to obtain illegal copies of components.

Techniques used by illegal manufacturers: non-functional equipment, sandblasting and observation, blackening, replacing equipment, using scrap, forging labels, etc.

The first thing to do is to perform a series of tests and controls on the electronic components to ensure their integrity (AOI testing, electrical, impedance, metallographic cutting or X-ray).

The X-ray machine provides accurate, non-invasive inspection of molds, welds and layers. Then, you simply compare the manufacturer's specifications to verify the component's authenticity. By the same logic, the electrical tests performed on the suspect components provided tolerances sufficient to be compared with the manufacturer's data. If the gap is too large, further investigation should be conducted.

If the height, length, and width are measured and compared to the manufacturer's specifications, the height, length, and width can also be inferred or not inferred if the components are relative. A method often used by forgers to cover up black spots is to hide the original serial number and reprint another mark at the top to mislead buyers. Undetectable to the naked eye, but a skilled eye can detect fraud under a microscope. Acetone can also be used to remove the wrong mark.

Ultimately, removing the component is invasive and therefore destructive. However, this process is still the ultimate solution for seeing what you have when all other tests fail to ensure compliance. Use a powerful microscope to check the authenticity of manufacturer's trademarks, defective parts, typography and serial numbers. Prevention of counterfeiting

Buy directly from the manufacturer

Direct supply to manufacturers seems to be a reliable solution that minimizes risk, and the addition of middlemen reduces transparency and increases risk.

Know your provider

The U.S. Government Information Sharing Program is a database that lists components of North American industry suspects that are fake. To ensure the integrity of your suppliers, there are other places to check:

Does your supplier want to make the supplier list as public as possible?

Does it comply with the international standard AS6081 on fraud and counterfeiting of electronic parts?

Does your supplier ensure that the minimum testing required by international standard AS553A is performed?