Four types of SMT machine structure

In the selection of SMT mounters, we first need to start from the point of view of speed and accuracy, and then to study it and other conditions, such as structural type, product brand, product information (such as origin), they can help us. In order to choose the most suitable machine, today we describe all four structural types of SMT mountings. https://www.kingfordpcb.com/yuan.php

https://www.kingfordpcb.com/yuan.php

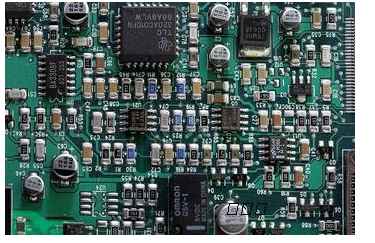

The arch arch frame is the most traditional SMT mounting machine, with good flexibility and accuracy, suitable for most parts. High-precision machines are usually of this type, but their speed is not comparable to that of composite, turret, and large parallel systems. However, component layouts are increasingly focused on active components, such as QFP and wired BGA, where installation accuracy plays an important role in high performance. Composite systems, turntable systems and large parallel systems are generally not suitable for such component installation. Bow machine is divided into single arm machine and dobby machine. The single-arm machine was one of the first multifunctional SMT patch machines developed and isstill in use today. On the basis of the development of single-arm dobby, doubling the SMT placement machine can improve work efficiency. Most SMT chip suppliers will introduce the construction of high-precision SMT mounters and SMT mounters at a medium speed. 2. The concept of the tower is to use a set of mobile paper feeders from which the tower extracts elements and then pastes them onto a circuit board on the mobile table. The installation speed is greatly improved because the turret is picked up and installed at the same time. After more than ten years of development in China, this high-speed assembly machine structure is not only very fast, but also very mature. However, due to the limitations of the mechanical structure, the mounting speed of this mounting machine has reached the limit value and cannot be greatly increased. The disadvantage of this machine is that only strips of material can be used.

Turtle type assembly machine is mainly used for mass production of computer boards, mobile phones, household appliances and other products, because the resistance and capacitance components in these products, high assembly density, very suitable for this kind of production. 3. Compound

The SMT composite laying machine is developed on the basis of the arch surface laying machine, and the SMT machine has both tower and surface characteristics. Strictly speaking, the composite machine still belongs to the structure of the pen. Because the composite machine can increase the number of arms to increase the speed, it has great flexibility, so its development prospects are broad.

4. Parallel system

Large parallel systems use a series of small independent mounting units. Each unit has its own screw positioning system and is equipped with a camera and mounting head. Each mounting head can absorb a limited ribbon feeder to mount a portion of the printed circuit board that moves gradually at fixed intervals on the SMT mounter. Each unit runs slowly separately.