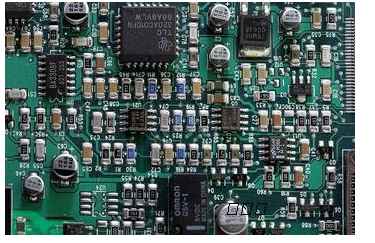

PCB printed circuit board of different methods

Different methods of assembling printed circuit boards

As with many processes in the electronics industry, PCB panels have countless possibilities and variations. Since each manufacturer has its own approach, you as a designer must choose from time to time to adjust your design accordingly or find other production partners. Here are three of the most common methods:

V-slot paneling: In this method, individual boards are separated from each other by milled V-shaped grooves that are one-third the height of the panel. The subsequent separation is carried out by a machine that is more suitable for straight cutting, so the method is especially recommended for PCBS that meet the following three requirements: no protruding components, no rounded corners, and sufficient distance between the component boundary and the PCB edge.

Panelization via strip wiring: Here, the board moves along its contours - while maintaining a small bridge of material that holds the board firmly in place during panel manufacturing and assembly. This type of paneling is not suitable for printed circuit boards with large transformers and other heavier parts that can make separation more complicated. At the same time, it should be noted that this method reduces the load on the printed circuit board, thus reducing the risk of fragmentation.

https://www.kingfordpcb.com/yuan.php.

https://www.kingfordpcb.com/yuan.php.

Disadvantages of PCB board

PCB panels are one way to protect your integrity. In addition, panelization allows Chinese PCB manufacturers to assemble multiple boards at the same time, which reduces costs and shortens production time. The panels must be manufactured correctly to prevent damage to the printed circuit board or damage during separation.

Challenges:

The panel presents many challenges in the following areas: 1

Paneling - Some disadvantages of de-paneling methods:

If a router is used, additional cleaning may be required prior to shipment. This method creates a lot of dust that must be removed.

2. Replace the pre-wired parts to avoid interfering with the splitter: prominent

Parts may fall into adjacent parts.

3. Incomplete data files -PCB manufacturers sometimes provide incomplete files, which can increase costs in a number of ways:

"Holes" or "mouse pits" - these holes allow small boards to be used in the array.

Cumulative and logarithmic tolerances - If there are no strict tolerances in the data file, the cumulative effect of small deviations can lead to errors. If there are multiple tables in the array, the record will no longer be centered. DFM and PCB panels

When companies develop printed circuit boards in large numbers, they look for ways to reduce manufacturing costs. If production details are discussed in detail early in the design process and considered in the development of the printed circuit board, this will require relatively little work. (Highly recommended). This early optimization of a design as opposed to a planned manufacturing process is often referred to as "production-oriented design" or "manufacturing design" (DFM for short).

There are several DFM methods that can enable you to save a lot of money in the long run. My preferred strategy is to simply connect with manufacturing companies early on and learn about their specific skills, challenges, and business models. In this way, I can learn which aspects of my design can be implemented easily (and therefore at lower cost) and which elements require extra effort (and correspondingly higher cost).

I benefited a lot from this a few years ago, for example, when I was designing amplifiers for speakers, I initially preferred a round PCB because it could be installed in an aesthetically pleasing way directly behind the round base of the speaker. However, when I discussed my idea with the manufacturer, it quickly became apparent that round (supposedly simple) PCBS were so expensive to manufacture that they greatly reduced the economic viability of the design.

So in the end, I decided to go with the standard rectangular design, which is much cheaper to manufacture. By adjusting the design accordingly, I can improve the profit margin of the final product and successfully complete the project.PCB board reduces costs

A low-level and widely used approach to DFM is called panelization. Using this method, various board designs can be applied to larger substrates or panels and then assembled in this way. The expected savings come from the ability to manufacture multiple PCBS simultaneously.

After completing the manufacturing and assembly process, the panels are divided into individual printed circuit boards. That way, you get a bunch of finished and (hopefully) fully functional PCBS all at once, waiting to be installed and sold. It sounds easy, doesn't it? But not so fast: In order to make the mass production of PCBS run as smoothly as possible and provide the required savings, there are some important details to consider when manufacturing panels.

Factors that affect the cost of PCB panels

Of course, most designers are less interested in the technical details of various processes than in the associated costs and challenges, and the basic rule of thumb here is that cost and effort depend on the complexity of the design to be made and to evolve with it. It should also be noted that panel-based manufacturing presents the following challenges, which also have an impact on costs:

Separation: If a fully assembled PCB is separated using a router, the chip and other debris will remain on the surface of the PCB and then have to be removed in another step at a later date, which involves work and additional costs. If you are going to use a saw instead of a router planer, when designing the board profile, keep in mind that only straight cuts can be made here. The third option is to use a modern laser, however, this laser can only be used for PCB thicknesses of 1mm or less, so in this case you cannot create multi-layer PCB designs of any thickness.

Fracture: Most separation processes leave a rough fracture on the side of the workpiece. - Especially in the case of paneling via flange wiring with perforated material Bridges (see above). In order to safely handle individual PCBS, they must be grounded at the relevant location, which in turn means additional work.

Hanging components: As mentioned earlier, protruding components can greatly limit the number of paneling methods available for your design. In this case, the separation of the finished PCB can also be problematic, as the milling head can collide with the protruding component, damaging the entire panel. Needless to say, such breakdowns involve unforeseen costs and delays.

The possibility of early detection and preventive action to address potential problems.

Experienced PCB designers rely on a variety of reliable methods to detect and correct potential problems early.

As mentioned earlier, a design based on the principles of DFM can effectively ensure that panels and production are as profitable as possible. For PCB panels, among other things, it is necessary to know the correct manufacturing company and its manufacturing process in the initial stages of the design project. This way, you can optimise your design for production from the start.

In addition, many of the challenges associated with automated PCB manufacturing will be easier to master if you use best-in-class design software. For example, AltiumDesigner® offers a wide range of capabilities for PCB panelization through the "Embedded Board Matrix" feature. This allows you to easily assemble panels with several identical or different PCB layouts. And, because the original design is not simply copied to the panel but linked to it, changes to the original design are immediately obvious in the panel design.

Of course, there are many other ways to save on manufacturing costs besides panels. However, this one deserves special attention, because mistakes here can quickly lead to unexpected additional costs or even a completely unsuitable PCB.

Therefore, you should definitely pay attention to the DFM tips and principles found here and in many other articles, and pay attention to production-oriented design throughout the design process. This not only saves you time, but also reduces manufacturing costs and the risk of late correction.

If you want to learn more about how Altium can help you overcome your dashboard challenges, talk to our experts today.

GERBER extends RS274-X-PCB data

- If your design system allows, use the RS 274-X extension device to export data. The main advantage is that all the information about the shape and size of the panel is included in the title. Importing data is easier, minimizing the risk of improper panel preparation, and also greatly reduces data processing time, which also reduces data preparation costs.