What information should be provided for PCBA processing production and quotation respectively?

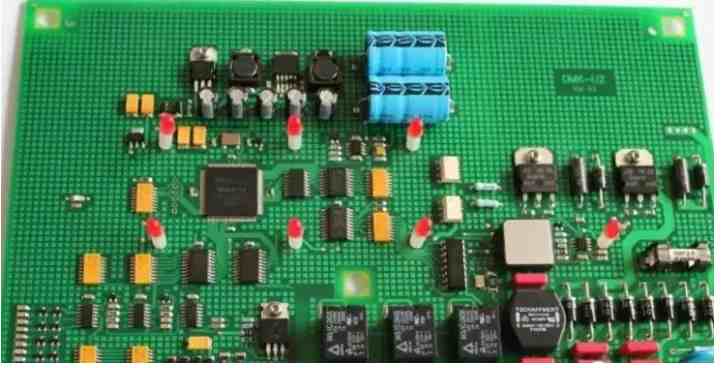

PCBA machining is a manufacturing process where electronic components are welded to a printed circuit board (PCB). It is an important link in the manufacturing process of electronic equipment. So, what information do PCBA processing production and quotation need to provide?

First of all, for the PCBA processing and production of the necessary application inf PCB processing ormation, here are some details you need to provide.

Circuit diagram design: Circuit diagram design is one of the core files ofand production, and it is the basis of PCB drawing. The design drawing should contain the circuit name, legend, circuit diagram, component list and indicator material, specification and other necessary content.

PCB engineering drawing: Secondly, PCB engineering drawing is also the core file of PCB processing. In the PCB engineering drawing, the details of the PCB board need to be displayed in detail, such as the location of the hole, material type and size.

PCB component list: The PCB component list lists all the component information used to build the circuit board, including the component name, component code, and component number, specifications, etc. It is one of the important documents in the production process of PCBA.

BOM table: BOM (Bill Of Materials) form is a complete list of parts, lists the name of each component, supplier, quantity, specifications and model information, is one of the core data of the entire PCBA processing and production process.

Component samples: In the PCBA production process, when we design a new circuit, we usually need to test with several samples. These samples help to check the quality and other performance parameters of the PCB, so their application is very important. https://www.kingfordpcb.com/yuan.php?time=1685694568

https://www.kingfordpcb.com/yuan.php?time=1685694568

The above information must be provided together with your PCBA processing order. No matter what kind of PCB you want, it is essential to provide complete and detailed information.

So, what other information do you need to provide for the PCBA quotation? Let's take a look at the following points:a

Circuit diagram design: As mentioned earlier, circuit diagram design is the key to electronic machining and has a great impact on PCBA quotation.

Component list: Similarly, the component information in the list is required for the accuracy of the PCBA quotation. The price of the component will affect the cost of production, so the component information in the quotation must be accurate.

Service requirements: You need to tell the PCBA processor which services you need. Include deadlines and delivery requirements.

Quantity and delivery Date: When you submit a quote to the PCBA processor, you need to inform the expected production quantity and delivery date. This information provides PCBA processors with the workload and time frame for production.

Contract Application: After you negotiate with the PCBA processor, the manufacturer will provide you with a contract application. Contract application includes production details, quotation, production quantity, delivery, maintenance and quality assurance.

To sum up, accurate and complete data is an indispensable element in the PCBA processing process. Especially in the quotation process, it is necessary to accurately understand the requirements of the required services and board design. Only in this way can we ensure the high quality and timeliness of production.