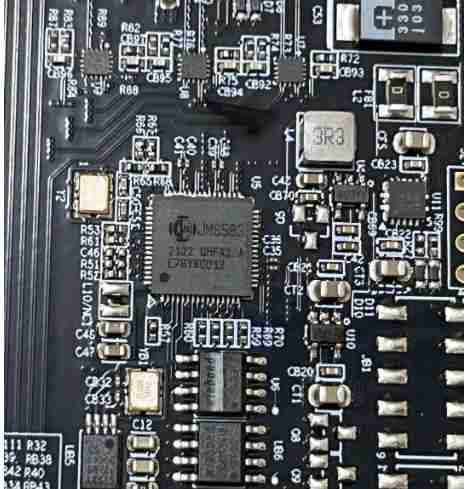

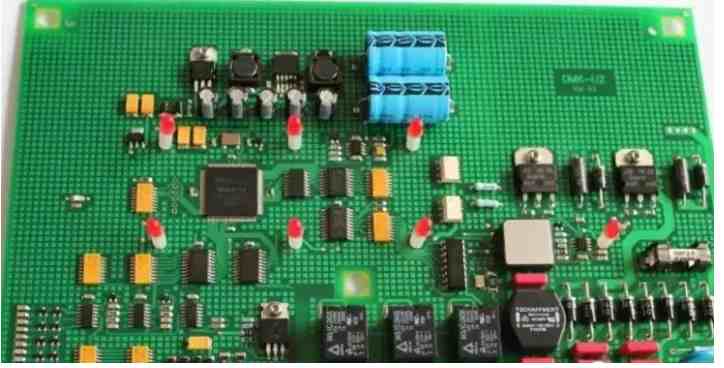

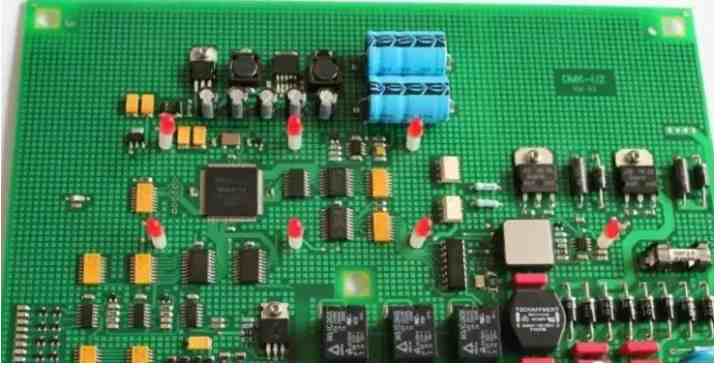

SMT patch processing is an efficient electronic manufacturing technology that can quickly attach electronic components (such as chips, capacitors, resistors, etc.) to the PCB surface. In this process, a large amount of solder paste is used to ensure a reliable connection between the components and the PCB surface. However, due to some reasons in the manufacturing process (such as improper operation, material quality, etc.), there will be excess solder paste and tin slag. Excess solder paste and tin slag will not only affect the mounting quality and reliability of electronic components, but also cause damage to the PCB surface. Therefore, the removal of excess tin slag is a very important step in SMT chip processing. Below, we will introduce some common methods of removing excess tin residue.

1. Manual cleaning method

Manual cleaning method is one of the simplest and most primitive methods to remove excess tin residue. It is mainly manually operated, using hand tools (such as scissors, scrapers, spray guns, etc.) to clean up excess tin residue. The advantage of this method is that it is simple and easy, does not require any equipment and materials, and only requires operators with certain skills and experience. In addition, the manual cleaning method can be personalized for different PCB boards and tin slag, with high flexibility and plasticity. However, the manual cleaning method also has many shortcomings, such as low efficiency, easy to make mistakes, high work intensity and low precision. Moreover, if the cleaning is not thorough, some small tin slag and stains may be left, affecting the quality and reliability of the PCB surface.

2. Solvent cleaning

Solvent cleaning is a commonly used method to remove excess tin residue. It is mainly through chemical reaction, the use of solvents to dissolve or separate the excess tin residue. In general, commonly used solvents include acids, bases, organic solvents and so on. The advantages of this method are high cleaning efficiency, the cleaning process will not cause damage to the PCB surface, and it is suitable for various PCB boards and tin slag. Moreover, the solvent cleaning method can also add some surfactants or emulsifiers to improve the cleaning effect and stability. However, the solvent cleaning method also has some shortcomings, such as low safety, complex operation and high cost. In addition, due to the uncertainty of the chemical reaction, the cleaning effect is also different.

3. Sticky tape cleaning method

Viscous tape cleaning is a commonly used method to automatically remove excess tin residue. It mainly sticks the adhesive tape to the PCB surface, sticks the excess tin slag to the tape, and realizes the purpose of automatic cleaning. The advantages of this method are high cleaning efficiency, high cleaning accuracy, and suitable for various PCB boards and tin slag. Moreover, the viscous coil cleaning method can achieve continuous automatic cleaning, improve production efficiency and quality stability. However, the adhesive tape cleaning method also has some disadvantages, such as higher cost, requiring more equipment and maintenance costs. In addition, for some relatively small tin slag or hard-to-reach locations on the PCB surface, the adhesive tape cleaning method may not be suitable.

4. Aerosol cleaning method

Aerosol cleaning is a commonly used method to remove excess tin residue. It is mainly by spraying a chemical cleaning agent on the PCB surface, and then rinsing excess tin slag from the surface through compressed air. The advantages of this method are high cleaning efficiency, high cleaning accuracy, and suitable for various PCB boards and tin slag. Moreover, the aerosol cleaning method will not cause damage to the PCB surface, and the solubility and fluidity of the cleaning agent can also be effectively controlled. However, the aerosol cleaning method also has some disadvantages, such as high equipment cost, complex operation, and environmental and health effects.

5. Paint cleaning method

Paint cleaning method is a novel method to remove excess tin residue. It mainly achieves the purpose of cleaning by coating a layer of paint on the PCB surface, and then after the paint dries, the excess tin slag and paint are stripped together. The advantages of this method are high cleaning efficiency, high cleaning accuracy, and less impact on the PCB surface and the environment. Moreover, the coating cleaning method can be customized according to different PCB boards and tin slag, improving the cleaning effect and stability. However, the paint cleaning method also has some shortcomings, such as complex operation, the need for certain technology and experience, and the high cost of paint.

The above are several common methods to remove excess tin slag, according to the actual situation and requirements of production, you can choose different methods for cleaning. At the same time, no matter what method is used, attention should be paid to safety and environmental protection and other issues.