LED aluminum substrate package is mainly to provide a platform for LED chips, so that LED chips have better light, electricity, thermal performance, good packaging can make LED have better luminous efficiency and good heat dissipation environment, good heat dissipation environment and then improve the service life of LED. LED packaging technology is mainly built on five main considerations, namely optical takeout efficiency, thermal resistance, power dissipation, reliability and cost performance (Lm/$).

Each of the above factors is a very important link in the package, for example, the light takeout efficiency is related to the cost performance; Thermal resistance is related to reliability and product life. Power dissipation is relevant to customer applications. Overall, the best packaging technology is to take into account every point, but the most important thing is to stand in the customer position to think, to meet and exceed customer needs, is a good package.

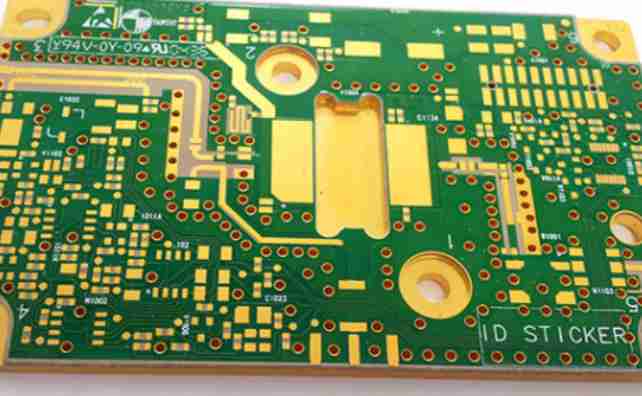

A single or double layer aluminum substrate is usually used as a heat sink, and a single chip or multiple chips are directly fixed on the aluminum substrate (or copper substrate) with solid crystal adhesive, and the p and n electrodes of the LED aluminum substrate chip are bonded on the thin copper plate on the surface of the aluminum substrate. According to the size of the required power to determine the number of led chips arranged on the base, can be combined into 1W, 2W, 3W and other high-brightness high-power LED. Finally, the integrated LED is packaged in an optically designed shape using a material with a high refractive index.

Talk about the six unique advantages of aluminum substrate

1, meet the needs of RoHs;

2, more suitable for SMT technology;

3, in the circuit design scheme for thermal diffusion is very useful treatment, and then reduce the module operating temperature, extend the service life

4, life, improve power density and reliability;

5, reduce the installation of heat sinks and other hardware (including thermal interface data), reduce the volume of goods, reduce hardware and installation costs; Optimal combination of power circuit and control circuit;

6, replace fragile ceramic substrate, obtain very good mechanical durability.

Aluminum substrate (metal-based cooling plate (including aluminum substrate, copper substrate, iron substrate)) is a low alloying Al-Mg-Si series of high plastic alloy plate (see the structure below), it has excellent thermal conductivity, electrical insulation function and machining function, aluminum substrate and traditional FR-4 compared, the same thickness, the same line width, the same thickness, the same line width, the same thickness, the same line width. Aluminum substrate can carry higher current, aluminum substrate can withstand pressure up to 4500V, thermal conductivity greater than 2.0, in the industry to aluminum substrate based.

Use surface mount technology (SMT); Street lamp aluminum substrate

It is very useful to deal with thermal diffusion in circuit design.

Reduce the operating temperature of the commodity, improve the power density and reliability of the commodity, and extend the service life of the commodity;

Reduce the volume of goods, reduce hardware and installation costs;

It replaces the fragile ceramic substrate and achieves very good mechanical durability.

Innovation, development, transformation and upgrading of enterprises

In the face of the new era pattern of China's industry 2025 and Industry 4.0, many large and small PCB enterprises are eager to actively respond to the requirements of the new era and develop in the big pattern. Chen Tao, vice chairman of CPCA and chairman of the listed company Shenghong Technology, proposed that enterprises can only move towards the future through innovation and development. When it comes to how to innovate, he believes that while enterprises achieve concept innovation, research and development innovation, and accelerate transformation and upgrading, they should also actively build green brands and promote fine management in order to obtain a place in the tide of enterprise development.

Finally, CPCA, by the chairman of the board, expressed his views on the current situation of the PCB industry. He believes that China's PCB industry is in the stage of adjustment and reshuffle period and development opportunity period, in the process of pursuing manufacturing and information technology in the manufacturing industry, the development of PCB industry should be in the search for selling points and characteristics of brand development, intelligent development. At the same time, relevant associations should also actively lead, assist the government to seek more development space for the PCB industry, but also actively call on the awareness of energy conservation and environmental protection of enterprises, carry out more business model learning and discussion, and actively build a platform for the formation of a good PCB industry chain.