Aluminum substrate and FR4 board are common circuit board boards, so what is the difference between aluminum substrate and FR4 board?

The comparison of wire (copper wire) and fuse current on different substrate materials, from the comparison of aluminum substrate and FR-4 plate, due to the high heat dissipation of the metal substrate, the conduction is significantly improved, which explains the high heat dissipation characteristics of the aluminum substrate from another Angle. The heat dissipation of aluminum substrate is related to its insulating layer thickness and thermal conductivity. The thinner the insulation layer, the higher the thermal conductivity of the aluminum substrate (but the lower the pressure resistance).

2. Different machinability

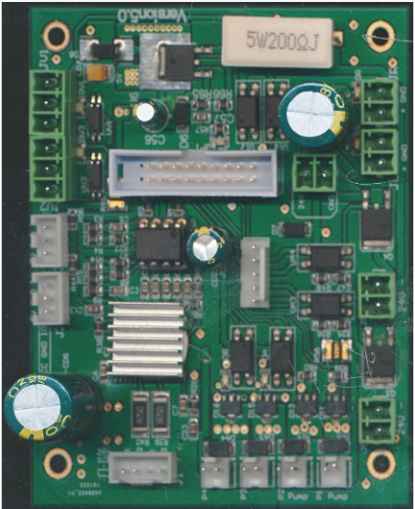

Aluminum substrate has higher mechanical strength and toughness than FR-4 plate. For this purpose, a large-area printed board can be made on an aluminum substrate, on which large components can be installed

3. Electromagnetic shielding performance is different

In order to ensure the performance of the circuit, some components in the electronic product need to prevent the radiation and interference of electromagnetic waves. The aluminum substrate can be used as a shielding plate to shield electromagnetic waves.

4. Different coefficient of thermal expansion

Due to the thermal expansion of FR-4 in general and the thickness of the plate in particular, the quality of the metallized holes and lines is affected. The main reason is that the thermal expansion coefficient of the thickness of the copper in the raw material is 17 * 106cm/cm-C, and the FR-4 plate is 110 * 106cm/cm-C, and the difference is large, which is easy to produce heated substrate expansion and the change of the copper wire and the damage of the metal hole rupture on the reliability of the product. The thermal expansion coefficient of aluminum substrate is 50×106cm/cm-C, which is smaller than that of ordinary FR-4 plate and close to that of copper foil. This is conducive to ensuring the quality and reliability of the printed circuit board.

5. Different application fields

FR-4 board is suitable for general circuit design and ordinary electronic products, aluminum substrate is often used for high heat dissipation requirements of electronic products, such as LED lamp board.

Energy production from 2 layers to 14 layers, 14-22 layers can be proofing production.

Minimum line width/spacing: 3mil/3milBGA Spacing :0.20MM Minimum aperture: 0.1mm Size :610mmX1200mm Ink: Japan Tamura, Taiyo, Fudoken;

FR4: Shengyi, Kingboard, Haigang, Hongren, Guoji, Hezheng, Nanya, (Shengyi S1130/S1141/S1170),Tg130℃/ Tg170℃ T g180℃ and other high TG plates)

High frequency board: Rogers, Taconic, ARLLON; Surface process: spray tin, lead-free spray tin, sinking gold, full plate gold plating, plug gold plating, full plate thick gold, chemical sinking tin (silver), anti-oxidation (OSP) blue glue, carbon oil

1. Strength guarantee

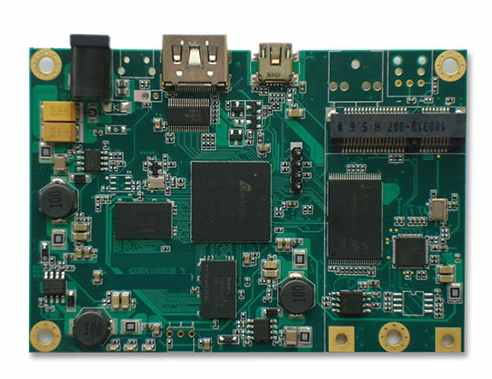

▪ SMT workshop: With imported SMT machines and a variety of optical inspection equipment, it can produce 4 million points per day. Each process is equipped with QC personnel who can keep a close eye on product quality. ▪ DIP production line: There are two wave soldering machines. Among them, there are more than 10 old employees who have worked for more than three years. Skilled workers can weld all kinds of plug-in materials.

2. Quality assurance, high cost performance

▪ High-end equipment can mount precision parts, BGA, QFN, 0201 materials. Proof can be machine paste, also can hand swing.

▪ Samples and large and small batches can be produced. Proofing starting price 800 yuan, batch starting price 0.008 yuan/point, no start-up fee.

3. Rich experience in SMT and welding of electronic products, stable delivery time ▪ Accumulated service for thousands of home appliance subsidiaries, involving various types of automotive equipment and industrial control motherboard SMT processing services. Products are often exported to Europe and the United States, and the quality is affirmed by new and old customers. ▪ On-time delivery, generally delivered within 3-5 days after the board is assembled, small batch expedited can also be shipped on the same day.

4. Strong maintenance ability, perfect after-sales service

▪ Experienced maintenance engineers can repair bad products caused by various welding problems, and can ensure the connectivity of each circuit board. ▪ 24-hour customer service staff will be ready to respond and resolve your order as soon as possible.