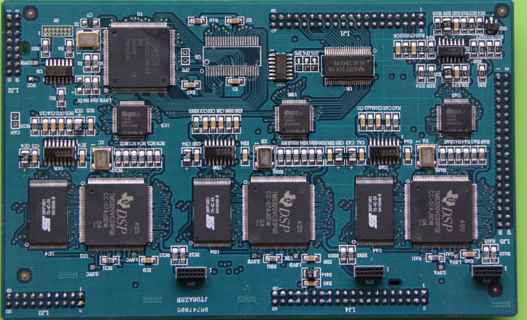

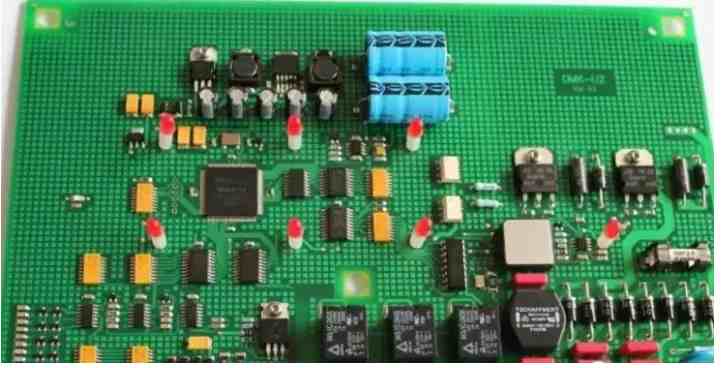

SMT patch proofing is a very important processing link in the process of electronic processing, the precision of SMT patch proofing processing is also very high, and many bad phenomena of electronic processing are some problems in the process of SMT processing production. Printing failure is a common processing phenomenon in the process of patch processing, so most electronics processing plants will strive to improve the quality of patch printing, to solve and avoid printing failures.

The steel mesh is originally made of wire mesh, so it is called the mesh board. At first it was nylon (polyester) mesh, and later due to durability, barbed wire appeared. Copper wire mesh, and finally stainless steel mesh. But no matter what the material of the wire mesh, there are poor forming wire mesh. Disadvantages of low precision. SMT with the development of the board and the requirements of the board. Affected by the cost of materials and the difficulty of production procedures, the original steel mesh was made of iron/copper plates, but due to easy corrosion, stainless steel mesh replaced them, that is, the current steel mesh.

The printing method with no gap between the steel mesh and the circuit board is called touch printing. It requires the stability of all structures and is suitable for printing high-precision solder paste. The contact between the steel mesh and the circuit board is very flat, and it is separated from the circuit board after printing. Therefore, the method has a high printing accuracy, especially suitable for thin spacing and ultra-fine spacing solder paste printing.

Solder paste printing principle: solder paste through the steel plate hole release contact solder paste, printed on the substrate tin pad (PCB plate solder pad).

1.Scraper type: plastic scraper and steel scraper, the spacing does not exceed 0.5mm IC, steel scraper for printing, easy to print solder paste molding.

2. Adjusting the running view point of the scraper to 45° in the printing direction can significantly improve the imbalance of different steel mesh opening directions of the solder paste and damage the fine-spaced steel mesh opening; The scraper pressure is usually 30N/mm².

3. Printing method: The most common printing method in SMT processing is divided into "touch printing" and "non-touch printing". The printing method with a gap between the steel mesh and the circuit board is "non-touch printing". Usually the gap value is 0.5~1.0mm, which is suitable for solder paste with different viscosity.

4. Printing speed: Under the push of the scraper, the solder paste will roll on the steel net. The SMT patch proofing printing speed is fast, which is conducive to the rebound of the steel mesh, but it will also hinder the solder paste printing; If the speed is too slow, the solder paste will not roll on the steel mesh, resulting in poor solder paste resolution printed on the pad. The printing speed of the fine interval is usually 10~20mm/s.

kinhford one-stop PCBA OEM processing factory, R & D template/small batch, SMT patch,PCB proofing, DIP welding processing,PCB board, electronic components full set of purchasing, some purchasing one-stop PCBA manufacturing services.