Due to the rapid development of electronic products in the industry of SMT chip processing, SMT manufacturers have more and more requirements for quality, especially the quality of chip processing. Strictly in accordance with the requirements of electronic processing for production and processing is bound to improve the quality of processing, then what should be done specifically? Next, SMT manufacturer - Electronics introduces the preservation method of SMT chip processing temperature and humidity sensitive components.

First,Environment

The operating environment of the sensitive parts has certain temperature requirements, which must be between 18 degrees and 28 degrees, and the humidity should be between 40 and 60 percent. The humidity during storage should be appropriately lowered, and the temperature is the same.

Second, the process

1. When disassembling components on the SMT patch production line, the processing and production operators must wear anti-static wristbands, gloves and wrist straps to open the vacuum packaging on the basis of good electrostatic protection.

2, if received in bulk humidity components, these components should be inspected according to the "humidity sensitive components Control label" to see if qualified, if qualified, priority use, if not, according to the normal process.

3. After unpacking, before backwelding, the exposure time must not be too long.

4, for unqualified components, direct return to the warehouse can not be used in SMT OEM.

Third. Management and Control

1, feeding: moisture-proof bag must have a desiccant bag, the corresponding humidity card, moisture-proof bag also has relevant labels, including bad packaging, need to be confirmed by relevant personnel.

2, storage: If the SMT temperature and humidity sensor is not opened, store according to the instructions, if it is opened, it should be returned to the warehouse, after baking and bagging, vacuuming can be used in the SMT. If the opening material is not used for the time being, it must be stored in a low temperature oven and cannot be placed at will. Operation: During the operation, the processing and production personnel strictly check the quality of the device and fill in the humidity indicator card, and the information should be filled in when refuelling, and the return situation should also be packaged and stored according to the regulations.

4. Dehumidification: Set baking time and conditions according to SMT processing grade, different environment, humidity, opening time, etc.

1. Strength guarantee

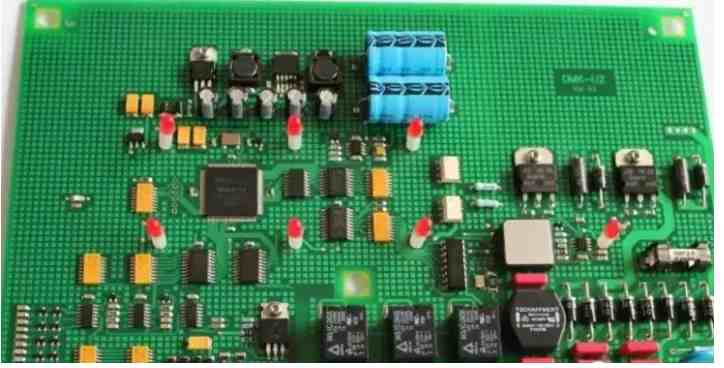

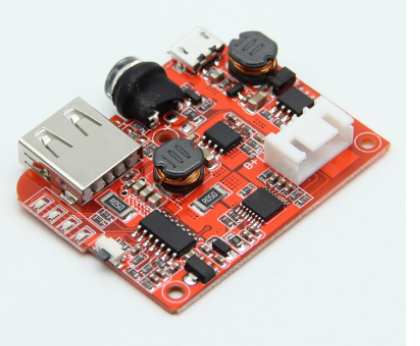

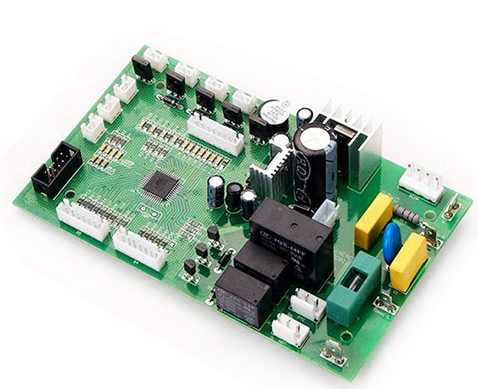

▪SMT workshop: With imported SMT machines, optical inspection equipment, can produce 4 million points per day. Each process is equipped with QC personnel, who can keep an eye on product quality.

▪DIP production line: there are two wave soldering, of which there are more than 10 old employees who have worked for more than three years. The workers have high proficiency and can weld all kinds of plug-in materials.

2. Quality assurance, cost-effective

▪ High-end equipment can be attached to precision shaped parts, BGA, QFN, 0201 materials. Also can be template patch, loose material hand. Sample and size batch can be produced, proofing from 800 yuan, batch 0.008 yuan/point, no start-up fee.

3. Rich experience in SMT and welding of electronic products, stable delivery

▪ Accumulated service for thousands of electronic enterprises, involving many types of automotive equipment and industrial control motherboard SMT processing services, products are often exported to Europe and the United States, quality can be affirmed by new and old customers. Delivery on time, normal 3-5 days after complete materials, small batches can also be expedited on the same day.

4. Strong maintenance ability, perfect after-sales service

▪ Experienced maintenance engineers can repair all kinds of patch welding caused by bad products, to ensure the connectivity of each circuit board. 24-hour customer service staff is ready to respond, the fastest to solve your order problems.