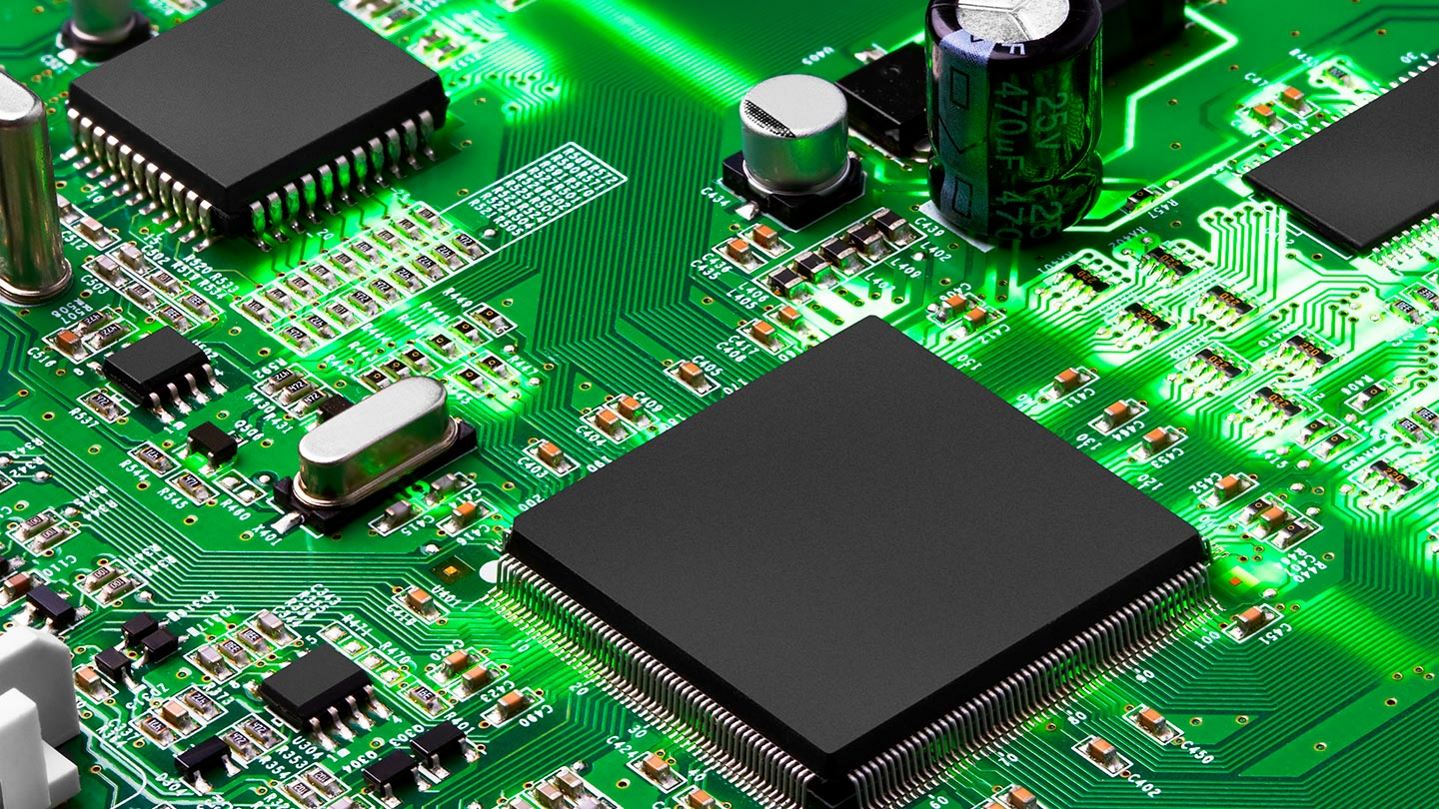

1, using surface mount technology (SMT).

2, in the circuit design scheme for thermal diffusion is extremely effective treatment.

3, reduce the operating temperature of the product, improve the power density and reliability of the product, extend the service life of the product.

4, reduce product volume, reduce hardware and assembly costs.

5. Replace the fragile ceramic substrate to obtain better mechanical durability. Here to share an article "Detailed concept of Aluminum substrate"

Aluminum substrate also has the following unique advantages:

Meet RoHs requirements.

More suitable for SMT process.

Optimal combination of power circuit and control circuit.

Reduce the assembly of heat sinks and other hardware (including thermal interface materials), reduce product size, and reduce hardware and assembly costs;

Replace fragile ceramic substrate for better mechanical durability;

Thermal diffusion is treated very effectively in the circuit design scheme, thus reducing the module operating temperature, extending the service life, and improving the power density and reliability.

For the above about the characteristics and advantages of LED aluminum substrate better let us know what kind of benefits it has.

FPC cable design skills

1. the line into the arc mode

2. in the shape of the bend, the edge of the inner diameter should be added protection strip

3. try not to use solid copper, the use of grid copper can improve the number of FPC bending

4. wiring and through the hole connection, in order to strengthen the mechanical reliability, increase the teardrop processing

5. the hole should not be played in a straight row, the need to stagger the placement, to prevent affecting the bending of the board, and even cause the board to break

2015 global FPC (flexible circuit board) industry market size analysis forecast

1. Industry development history

FPC manufacturing industry appeared in the 1960s, the United States and other countries with advanced electronic technology were the first to apply FPC to aerospace and military and other sophisticated electronic products. After the end of the Cold War, FPC began to be used in civilian products. At the beginning of the 21st century, the rapid development of the consumer electronics market has promoted the FPC industry to enter a period of rapid development. However, due to the continuous increase in production costs in Europe and the United States, the focus of FPC production has gradually shifted to Asia, forming the first wave of FPC industry transfer. This wave has made the FPC industry in Japan, South Korea, Taiwan and other countries and regions with a good manufacturing base and production experience grow rapidly. In recent years, Japan, South Korea and Taiwan are also facing the problem of rising production costs, and the FPC industry has begun a new industrial transfer. FPC manufacturers in developed countries have invested and set up factories in China, and China, as the main undertaking country of the FPC industry, has benefited from the new wave of industrial transfer.

The FPC industry in mainland China developed slightly later, and sporadic FPC process research and development began in the late 1980s, and the products were mainly used in military and high-end electronic production. In the early 1990s, the development of electronic products in mainland China was slow, and the development of FPC industry was slow; In the late 1990s, influenced by the acceleration of FPC technology progress and the continuous transfer of electronic products industry to mainland China, FPC demand was rapid and strong, and the industry began to break out.

2. Global industry development status

At the beginning of the 21st century, the FPC industry grew rapidly, and from 2003 to 2008, the average annual growth rate of global FPC output was about 6%. In 2009, affected by the macro environment, the output value fell by 9.33%, falling back to 6.8 billion US dollars.

With the recovery of the global economy in the past two years, the sales of smart electronic products have increased rapidly. FPC, as the most suitable printed circuit board for smart electronic products, has become one of the biggest beneficiaries of the development of the smart electronics industry, the industry has returned to the upward channel, and its market share has also been improved with the changes in the electronic products market environment and the changes in the world PCB market pattern.

FPC with its superior performance, the application field continues to expand, become the fastest growing PCB type, accounting for a rising proportion of the PCB market. In 2012, the world's total PCB output value was affected by the slowdown of the global economic recovery, which fell by 2.0% compared with 2011, but the FPC output value reached 10.788 billion US dollars, an increase of 17.2%, accounting for 19.86% of the total output value (the proportion increased by about 3.2% compared with 2011). Ranked first in the annual growth rate of output value of the five major PCB types. In 2013, the total output value of global PCB reached 56.1 billion US dollars, of which FPC still maintained a good growth momentum, with a growth rate of 8.7% ahead of the remaining categories of PCB, and the proportion further rose to 20.9%, becoming the most growing part of the PCB industry.

The research shows that the global FPC industry will continue to maintain a steady and rapid development momentum, and the output value will reach 14.24 billion US dollars by 2015; By 2017, the world's total PCB output value will reach 65.654 billion US dollars, of which FPC output value will reach 15.663 billion US dollars, a compound annual growth of 7.7%, ranking first in the five types of PCB, and the proportion of PCB output value further rose to 23.86%, becoming the fastest growing sub-industry in the PCB industry.