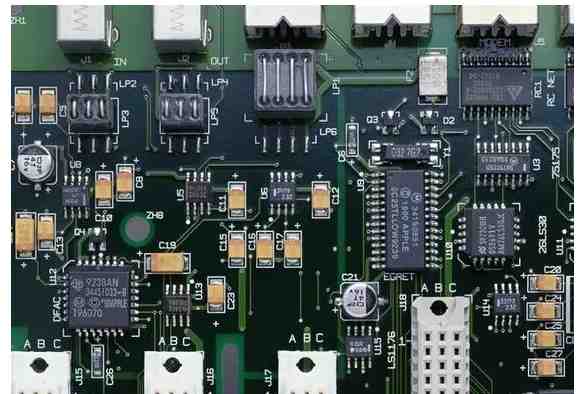

Poorly welded electronic components. In the face of this situation, we generally remove poorly welded electronic components without damaging the PCB board. Today, kinhford Electronics, the manufacturer of PCB Assembly, will introduce you to the detsolder method of PCB Assembly.

(1) Split-body welding method: For horizontally installed resistance capacitor components, the distance between the two welding points is relatively long, and the electric iron can be used for point heating and point-by-point pulling out. If the pin is bent, pry it up directly with the soldering tip and remove it. When dissoldering, stand the PCB upright, use an electric soldering iron to heat the pin solder of the component to be removed, hold the pin of the component with tweezers or needle-nose pliers, and gently pull out.

(2) centralized desoldering method: Because the pins of the resistance are welded separately, it is difficult to heat with the electric iron at the same time. A hot air welder can be used to quickly heat several solder joints, and the solder can be pulled out after melting.

(3) Welding method: Use soldering tools to absorb solder joints. Typically, you can remove the component. If multi-pin electronic components are encountered, they can be heated with the help of an electronic thermal fan.

If it is a lap-welded component or pin, you can apply flux to the solder joint, weld the solder joint with an electric soldering iron, and remove the pin or wire of the component. If it is a hook welding element or pin, first remove the solder at the solder spot with an electric iron, and then heat it with an electric iron to melt the residual solder under the hook. At the same time, use the spade to lift the pin along the hook line. Do not pry too hard to avoid melting solder into your eyes or clothing.

(4) Scissor welding method: If the pins and wires of the components on the removed solder joints have a margin, or it is determined that the components are damaged, the components or wires can be cut off first, and then cut off. Removes wire ends from pads.

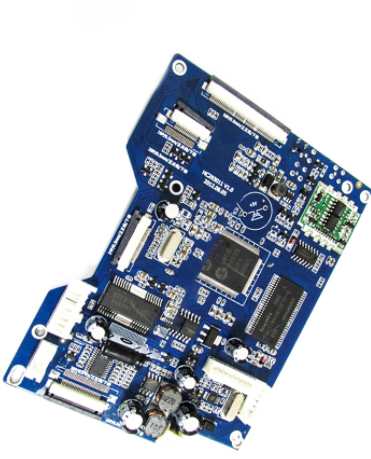

kinhford Electronics Co., Ltd. specializes in providing integrated PCB Assembly electronic manufacturing services, including upstream electronic component procurement to PCB production and processing, SMT patches, DIP plug-ins, PCBA testing, finished product assembly and other one-stop services

The company gives full play to its competitive advantages in scale procurement and quality control, and has signed long-term cooperation agreements with many electronic component manufacturers at home and abroad and around the world to ensure the quality and stable supply of raw materials, and transfer the benefits to customers.

Long-term maintenance of IC, resistors, capacitors, inductors, audiodes and other components procurement advantages, can greatly save customers' inventory costs, improve production turnover efficiency, save time. Currently for the United States, Britain, Japan, Russia, France, Canada, Australia, Romania, Switzerland and other countries and regions to provide PCBA processing services.

We provide PCBA processing services, starting from PCB circuit board production, our own PCB manufacturers (obtained the extremely strict automotive industry TS16949 certification), focusing on the quality of the circuit board and PCBA quality control system.

Due to decades of experience in purchasing electronic components, we maintain long-term cooperation with large brands to ensure the original packaging and procurement channels of components. In the packaging process of components, the selection of thousands and Locai solder paste to ensure the reliability of welding, with automatic printing press, Panasonic high-speed placement machine, upper and lower eight temperature zone reflow, AOI automatic optical detector, can effectively ensure the reliability and quality of electronic packaging process. In addition, perfect IPC, IPQC, OQA and other management processes, clear job responsibilities, strict implementation of IPC electronic assembly acceptance standards. For PCBA testing, we have professional engineers to perform 100% batch testing using a variety of test stands, including channels, noise, amplitude, signal, temperature, humidity, drop or to perform customer-specific test plans. All efforts are aimed at becoming a refined PCBA processing factory.