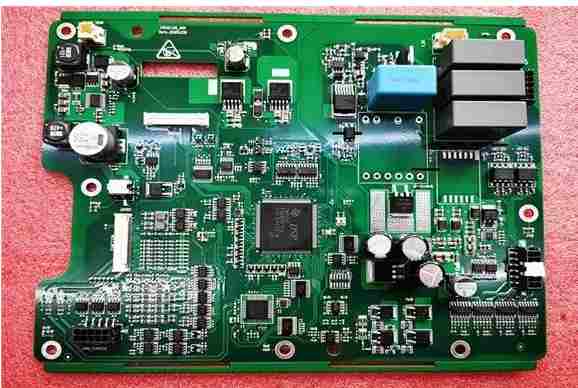

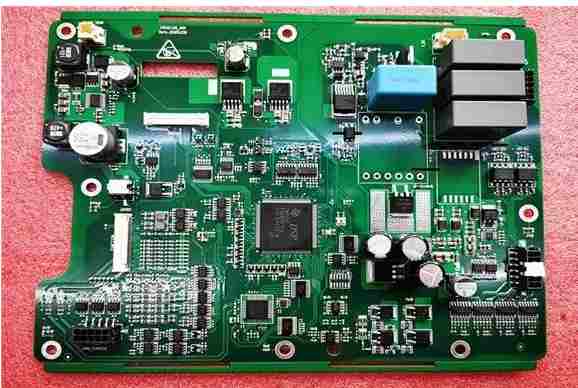

PCBA processing quotation time is the concern of many customers. In general, we say, how long does the PCBA quote and processing take? What are the PCBA manufacturing processes? PCBA is a general term for PCB welding materials and patch processing in China, including three main parts (PCB circuit board, SMT patch, component welding), then PCBA quotation must be determined by these three parts.

PCBA production process includes component procurement, PCB production, SMT patch processing, DIP plug-in processing and PCBA a series of processes, such as testing, involving complex processes. PCBA cost =PCB board cost + parts purchase cost +SMT patch /DIP Therefore, the time required to evaluate the welding cost of PCBA comprehensive evaluation of these three parts of the quotation is the processing quotation time.

PCBA In addition to the production time, the production cycle should also increase the material procurement time PCBA in the production time cycle, the material procurement and PCB production time is the longest.

Material purchase +PCB production cycle

Material procurement and PCB production are almost simultaneous. PCB production time is longer than material procurement time, but for some special materials or raw materials, the procurement cycle is relatively long, which will greatly increase the PCBA in the production cycle, and the delivery cycle of materials is relatively unstable. The following mainly describes the PCB production time.

1.Double panel is generally 4-5 days is enough, batch 12 days or so

2. 4.6 layer plate proofing 7-8 days, batch 25-30 days

3. Eight-layer plate proofing generally takes 8-10 days, batch 35-40 days

SMT+DIP cycle

The production time of SMT patches and DIP plug-ins is relatively short, but also depends on the difficulty of the process and the adequacy of factory orders. The normal lead time for proofing is about 1-3 days. Normal delivery time is about 5-7 days.

PCBA test

The proofing test is generally about 1-3 days, and the batch test is generally about 5-7 days. In practice, PCBA in the production process, in addition to different factors, will be affected by various factors, and the PCBA production cycle will fluctuate. Fourth, PCB board fee

PCB quotation required board materials and board instructions (such as Gerber documents). Coordinate file, etc.). If the information is complete, collating all the information, how much it costs for special processes, plus other miscellaneous expenses can basically report a complete set of prices in 2 hours. If there are a lot of offers to wait for, that's a different story.In addition, other costs involved in PCBA processing are mainly SMT patch processing and BOM parts procurement costs.

SMT patch processing fee

This module is mainly the accounting of processing costs, in general, PCBA factoriescalculate funds according to points. Some elements compute a point, and some pins compute a point. This is the biggest trick. A component has at least two pins. If a component calculates a point, the price of a single point may be higher than the price of a single pin. After all, there are very few points and no one is going into business at a loss, so don't look at a point. If it's expensive, don't evaluate it. In fact, this assessment can be done in less than an hour.

Component procurement costs

Parts include conventional resistance capacity and special parts. The conventional components currently on the market are transparent and the price is relatively easy to evaluate, but there are also some special BGA/ ics that will be more troublesome to add evaluation on the chip, because many special components will involve strict international embargoes and approval procedures. Due to price instability and other factors, the price of such components fluctuates greatly, so the quotation time is the longest, and the quotation cycle is generally 3-4 days. The above breakdown basically shows that PCBA quotes take several business days. Unless companies with their own reserves of materials can be evaluated in a very short period of time, other companies may just be PCB and SMT patches faster. There are also some situations, such as many orders, the quotation is very tight, it must be who came first, after all, the treatment of customers is equal.