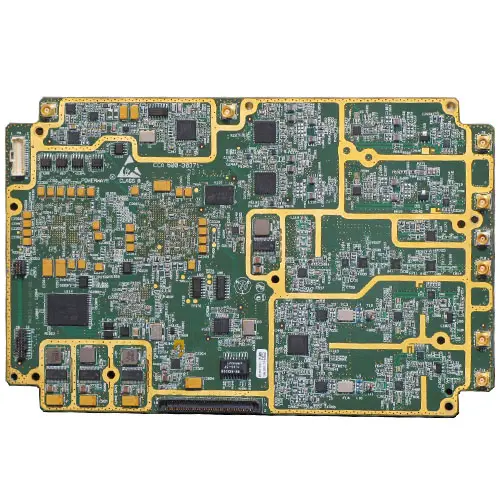

At present, the PCB circuit board products on the market are mainly divided into three types from the material category: ordinary substrate, metal substrate and ceramic substrate. Next, PCB board factory-electronics introduces the common metal substrate classification and its advantages

the classification of common metal substrates:

There are three main types of metal substrate: aluminum substrate, copper substrate and iron substrate. The aluminum substrate and copper substrate are mainly analyzed here.Aluminum substrate is currently the most used metal substrate substrate, with good thermal conductivity, electrical insulation properties and mechanical processing properties. Aluminum substrate is divided into flexible aluminum substrate, mixed aluminum substrate, multilayer aluminum substrate, through hole aluminum substrate and so on.

Copper substrate is one of the most expensive metal substrates, and its thermal conductivity is many times better than aluminum substrate and iron substrate. Copper substrate can be divided into gold-sunk copper substrate, silver-plated copper substrate, tin-sprayed copper substrate, copper oxide resistance substrate, etc.

the advantages of metal substrate:

1.thermal expansion metal substrate can effectively solve the problem of heat dissipation, so that the problem of thermal expansion and contraction of different substances on the components of the PCB circuit board can be alleviated, and the durability and reliability of electronic equipment can be improved.

2. At present, many double panels and multi-layer panels have high density, high power, and difficult heat dissipation; Metal-based printed boards can solve this heat dissipation problem.

3. Dimensional stability The size of the metal substrate is much more stable than that of the insulating material.

4, a wide range of applicationsAluminum substrate has a wide range of applications, such as audio equipment input, output amplifier, balance amplifier; Computer CPU board floppy disk drive, power supply device; Automotive electronic regulator, igniter, power controller; Lamp lighting LED lights, etc.

The copper substrate is mainly suitable for high-frequency circuits, including the heat dissipation of precision communication equipment in areas with large changes in high and low temperatures.

The number of layers of our metal substrate process capacity: 1-2L (metal substrate & metal core board), 1-2L (ceramic DBC board);

Plate thickness: 0.5-3.0mm

Size: max:400*500,

min:25*25mm;

Machining: X/Y/Z accuracy ±0.08mm, horn hole, screw hole;

Thermal conductivity of thermal conductivity materials: conventional thermal conductivity materials: 1-4W/m.k;

Ceramic thermal conductivity material: 24-170W/m.k;

Maximum wiring copper thickness: 5OZ;

Metal surface treatment: ordinary oxidation of aluminum, hard oxidation of aluminum, chemical passivation of aluminum, sandblasting, wire drawing, surface plating treatment;

Surface treatment process: hot air leveling, chemical gold sinking, tin sinking, silver sinking, electroplating soft/hard gold, etc.

PCBA processing service flow:

1. Project consultation/quotation: Customers provide complete PCBA information quotation;

2. Customer order: customer confirm the quotation, sign the contract, pay the advance payment;

3. Engineering evaluation: engineering evaluation of customer data, into the final production materials;

4. Purchase raw materials: Arrange PCB circuit board and component procurement according to production materials;

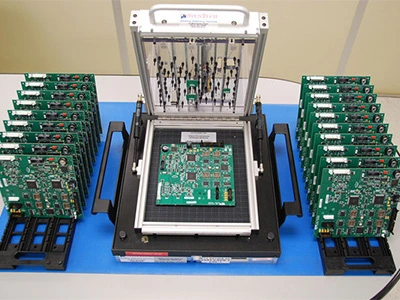

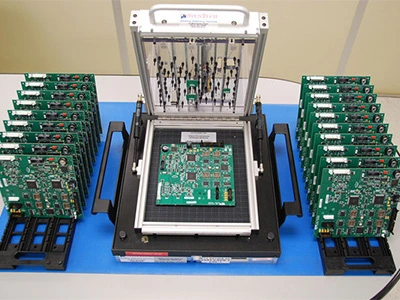

5. PCBA production: SMT, DIP welding process after the board is assembled;

6. PCBA test: Test products according to customer needs;

7. Packaging and after-sales: Customers pay the balance, PCBA packaging and shipment.