PCBA processing on the PCBA board tin bead size requirements, this requirement is determined by the customer, according to different products and customer requirements, the acceptable requirements for tin beads will be different, generally on the basis of the national standard, combined with customer requirements to determine the standard. Next PCBA processing manufacturer - electronics to introduce the PCBA processing tin beads acceptable standards.

Some industry standards explain tin beads. The categories range from no tin beads allowed in MIL-STD-2000 to less than five per square inch in IPC-A-610C.In the IPC-A-610C standard, the minimum insulation gap of 0.13 nm is specified, and the diameter of tin beads within this is considered qualified; Tin beads with a diameter greater than or equal to 0.13 mm are not qualified, and the manufacturer must take corrective measures to avoid this phenomenon. The latest IPCA-610D standard for lead-free welding does not clearly specify the phenomenon of tin beads. The requirement of less than five tin beads per square inch has been removed. However, the standards for automotive and military products do not allow any tin beads, so the PCB mustbe cleaned after welding, or the tin beads must be removed by hand.

The above is the introduction of the acceptable standard for PCBA processing tin beads. Next, we will introduce our PCBA processing capabilities and advantages.

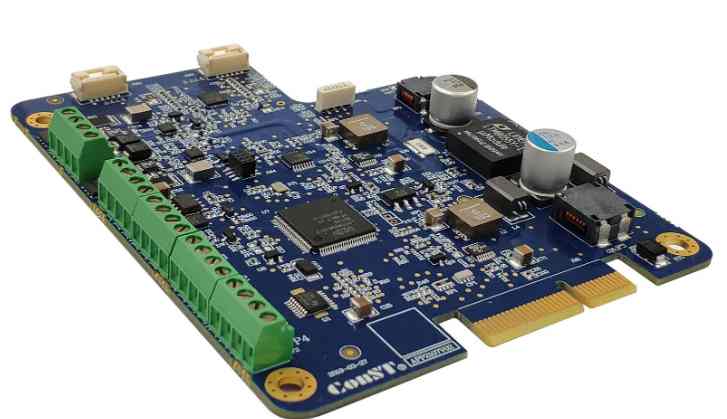

1. Maximum board: 310mm*410mm(SMT);

2. Maximum plate thickness: 3mm;

3. Minimum plate thickness: 0.5mm;

4. Minimum Chip parts: 0201 package or parts above 0.6mm*0.3mm;

5. Maximum mounting parts weight: 150g;

6. Maximum part height: 25mm;

7. Maximum part size: 150mm*150mm;

8. Minimum pin part spacing: 0.3mm;

9. Minimum ball parts (BGA) spacing: 0.3mm;

10. Minimum ball parts (BGA) ball diameter: 0.3mm;

11. Maximum parts mounting accuracy (100QFP) : 25um@IPC;

12. Patch capacity: 3-4 million points/day.

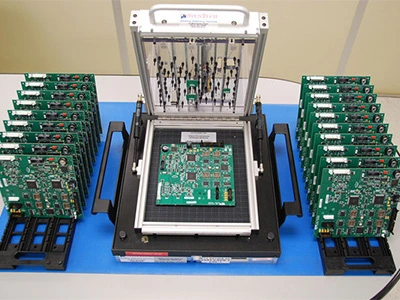

1.Highly professional: The company focuses on processing samples, small and medium-sized batches, and promises to deliver the materials within 3-5 working days after confirmation.

2. Professional equipment: The company's equipment is tailored for sample and small and medium-sized mass production of advanced equipment, can stick 0201, BGA spacing 0.3MM, QFN, CSP, CON and other components.

3. Professional technology: 100% of technical backbone more than 5 years of work experience, 85% of front-line operators more than 3 years of work experience.

4. The company implements the 5S and 6σ concept in daily operations to expect at least 7 checks on shipments. If the quantity reaches 100PCS, our company promises to pass AOI optical inspection.

5. The company promises that the welding pass rate is more than 99%, if the customer finds welding defects, the company promises to repair for free.