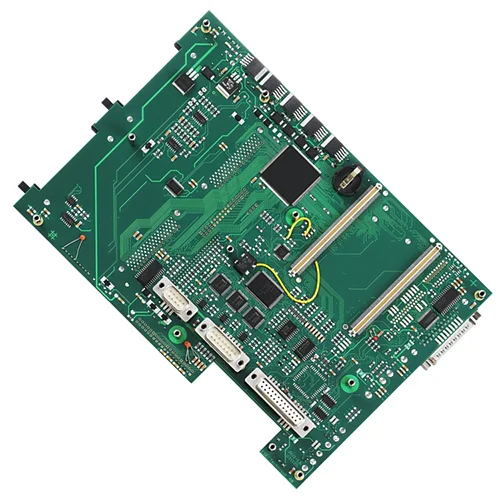

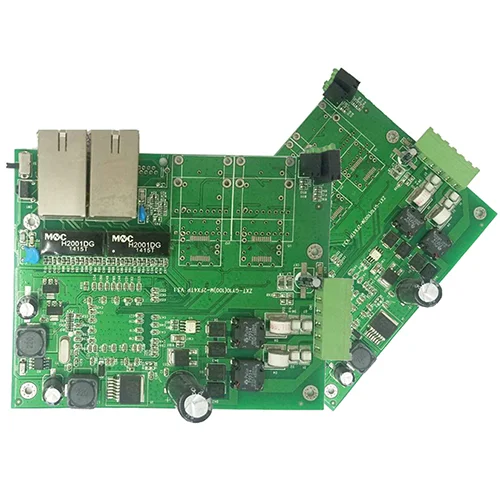

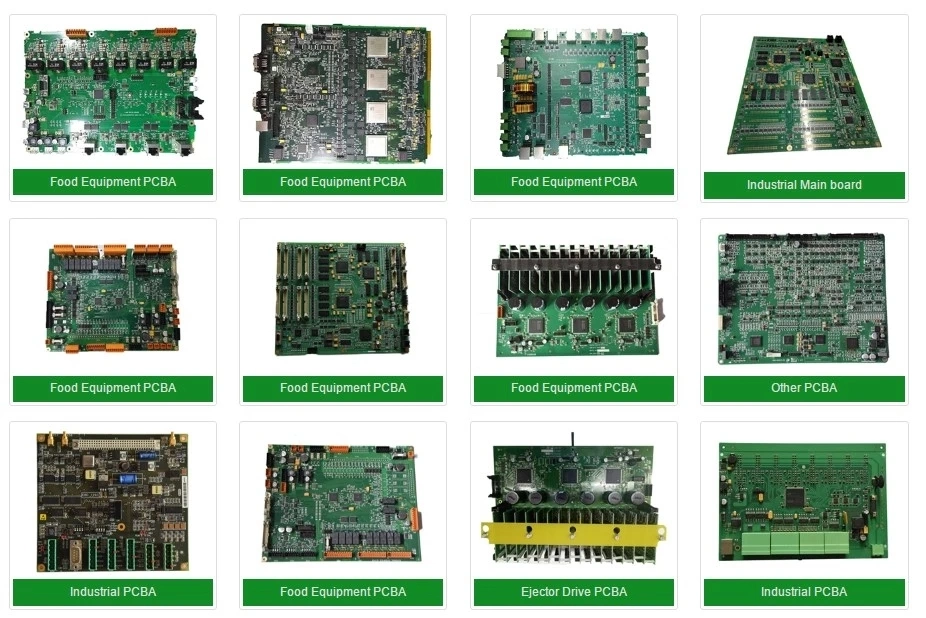

Small batch PCBA assembly supplier

Name: Small batch PCBA supplier

Substrate: FR-4/Polyimild/PTFE/Rogers

Copper Thickness: 1/3OZ- 6OZ

Plate thickness: 0.21-6.0mm

minute. Hole size: 0.20mm

minute. Line width: 4 million

minute. Line spacing: 0.075 mm

Surface treatment: spray tin/gold drill/OSP/lead-free spray tin

Board size: minimum 10*15mm, maximum 508*889mm

Product Type: OEM&ODM

PCB standard: IPC-A-610 D/IPC-III standard

Certificate: ISO9001/ CE//TUV/ ROHS

Warranty: 1 year

Service: One-stop turnkey service

Electronic testing: 100%

Logistics: Air/Sea

Small batch purchasing is an essential feature of time-based purchasing. An important difference between time-based procurement and the traditional procurement model is that time-based production needs to reduce production batches, so the purchased materials should also be purchased in small batches. Of course, small batch supply will increase the number of transportation and costs, especially in the case of long-distance suppliers, it will be more difficult to implement timely supply.

Batch procurement, that is, the centralized procurement of small-amount items, the applicable conditions are: single items below the bidding amount and in small quantities are purchased by individual units, but these items are items that are often needed by various government units at the same level; or single items The price is not high but the quantity is large. The specific procurement methods can be inquiry procurement, bidding procurement or negotiation procurement.

Minimal packaging problem

In the procurement of parts and components of electronic products, the parts are shipped out of the factory with a certain base as the minimum package. For small electronic components such as transistors, capacitors, resistors, and micro-processing chips, the minimum package base ranges from hundreds to many In the trial production of a product of tens of thousands of enterprises, the required quantity of various electronic components is only a few or even one, but they have to buy back components with a minimum packaging base, thus causing great waste and making the product R&D and trial production costs remain high. Except for electronic components, small batch purchases of small parts will face the problem of minimum packaging.

Minimum batch problem

In addition to the minimum packaging problem, small batch purchases sometimes also face the minimum batch problem. The so-called minimum batch refers to that due to the process or production equipment, the product cannot be produced with the smallest product unit, but must be produced with a certain base as the production unit, otherwise, the product cannot be produced. Therefore, the small batch procurement of products that need to be produced with a certain base as the minimum production unit due to process or equipment will face a minimum batch problem.

Minimum cost problem

For some products in the process of production and processing, there is no minimum batch requirement for processes and equipment, but in some processes, within a minimum quantity, the consumption of single-piece production and multi-piece production costs is the same. For example, some products are in the production process. One-time chemical potions are used in the production process, and the same amount of chemical potions is needed for single-piece production and hundreds of full-load production. Therefore, when calculating the unit cost of this process, single-piece production is hundreds of times that of mass production. In fact, this kind of problem will be encountered in the production of many products. The production cost of the product remains unchanged within a minimum base, but the cost of mass production is proportional to the multiple of the minimum base. Therefore, small batch procurement will also face a minimum cost problem.

Control Method

Seek an alternative

When the batch barrier of small batch procurement is difficult to break through, the procurement cost is high, and the purchased components are common components of similar products, enterprises can consider seeking procurement alternatives from similar manufacturers and purchasing a small amount of substitutes from similar manufacturers. In fact, it is very difficult for each raw material or component normally purchased by each production company to achieve the exact amount that is just used up. Therefore, in the raw material warehouse of a production company, various types of raw materials Or components often have a small amount of surplus. Therefore, for those small-volume purchases of parts or raw materials that may have substitutes in similar manufacturers, seeking procurement alternatives can sometimes greatly reduce procurement costs, because what you need may be It is the excess material that other similar manufacturers put in the warehouse and are rushing to process

Involve Technicians in Procurement

For the research and development and trial production of new products, if the production technicians are involved in the procurement, the batch size of the purchase can sometimes be reduced. For the trial production of new products, only technicians know the quantity of raw materials or original devices needed. If you let technicians communicate directly with suppliers, you can let suppliers know exactly the purpose and quantity of your purchases, and suppliers can share your purchases. A small number of components needed are arranged in other batch production, so that the required components can be purchased in batches smaller than the normal minimum batch, and the purpose of saving procurement costs can be achieved.

Form strategic alliances with suppliers

Small-volume procurement costs can also be reduced by forming strategic alliances with suppliers. If a manufacturer forms a strategic alliance with a supplier, the relationship between the two is no longer a simple procurement relationship, but a long-term strategic partnership of mutual benefit, and the two parties do not need to rush to withdraw in a transaction costs, but to achieve the balance of rights and obligations through long-term transactions. In the small batch procurement under this cooperative relationship, the supplier will not not produce or demand high prices because the batch is too small, but will find ways to save costs and fulfill their obligations for long-term cooperation.

Joint procurement

Joint procurement refers to a procurement method in which small and medium-sized production enterprises of the same type join together to purchase in order to gain a favorable position in the purchase price and expand the purchase batch. Due to the small scale of production, the passive position of small and medium-sized enterprises in procurement is obvious, but through cross-enterprise joint procurement, the procurement batch can be expanded and the procurement cost can be reduced. Where possible, small and medium-sized enterprises can consider organizing or joining a procurement alliance to unite in raw material procurement, which can increase the ability to prevent risks. A number of enterprises jointly purchase, combine small orders into large orders, enhance the collective negotiation power, obtain the advantages of procurement scale, and strive for the same "Jianghu status" as large enterprises; joint procurement directly faces the manufacturer, so that it can get rid of the agent The cost of changing hands, through direct transactions with manufacturers, reducing intermediate levels, greatly reducing circulation costs and ensuring product quality

Third party procurement

Third-party procurement is when a company outsources product or service procurement to a third-party company. Foreign experience shows that compared with the company's own procurement, third-party procurement can often provide more value and purchase experience, and can help companies focus more on core competitiveness. Third-party procurement mostly exists in the form of procurement alliances. Through small-volume procurement by third parties, small batches can be converted into large quantities. Coupled with the industry status and procurement experience of the procurement alliance, procurement costs can be greatly reduced.

Kingford supports Small batch PCBA supplier business, we are a professional PCBA one-stop assembly factory, welcome to place an order.

Name: Small batch PCBA supplier

Substrate: FR-4/Polyimild/PTFE/Rogers

Copper Thickness: 1/3OZ- 6OZ

Plate thickness: 0.21-6.0mm

minute. Hole size: 0.20mm

minute. Line width: 4 million

minute. Line spacing: 0.075 mm

Surface treatment: spray tin/gold drill/OSP/lead-free spray tin

Board size: minimum 10*15mm, maximum 508*889mm

Product Type: OEM&ODM

PCB standard: IPC-A-610 D/IPC-III standard

Certificate: ISO9001/ CE//TUV/ ROHS

Warranty: 1 year

Service: One-stop turnkey service

Electronic testing: 100%

Logistics: Air/Sea