With the update and iteration of the times, the medical electronic equipment manufacturing industry is facing fierce competition at all levels, so higher requirements and standards are put forward for medical equipment manufacturers. For Kingford, who focuses on PCB manufacturing and PCB assembly in the medical field It is undoubtedly both a challenge and an opportunity. In order to meet the requirements of the current medical market and provide stable and efficient production solutions, Kingford has passed the ISO13485 medical quality system certification and has innovated the production technology level.

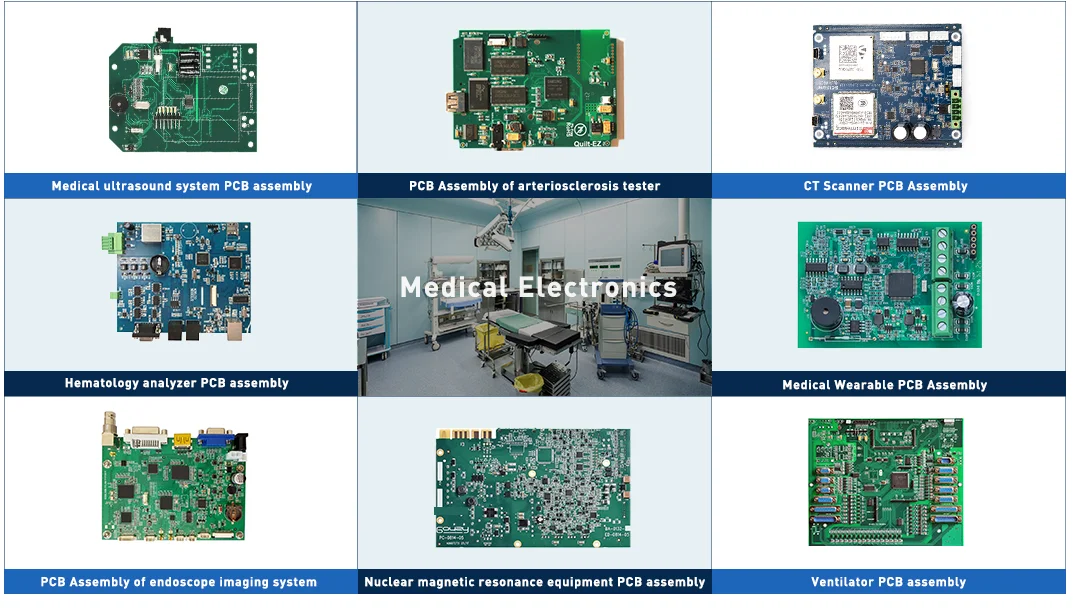

The application and development of medical PCBs continue to develop with medical devices. The most common ones in medical PCBs include:

Medical ultrasound systems, blood analyzers, endoscopic imaging systems, arteriosclerosis testers, MRI equipment, CT scanners, ventilators, etc., the core of these medical equipment is PCB. Medical PCBs tend to be specialized high-density interconnect PCBs that will stimulate the growth of high-density interconnect (HDI) PCBs in the market. PCB assembly applications in the medical and health sector include:

Medical ultrasound system PCB assembly:

medical devices developed according to the principle of ultrasound and used in the medical and health field to diagnose and treat diseases.

Hematology analyzer PCB assembly:

Hematology analyzer, also known as hematology analyzer, blood cell analyzer, blood cell counter, etc., is one of the most widely used instruments in hospital clinical testing.

PCB assembly of endoscope imaging system:

The endoscope generally has the characteristics of steerability and bending, which can penetrate into the cavity or conduct a more detailed all-round observation through the elbow.

PCB assembly of arteriosclerosis tester:

Arteriosclerosis detector is a device that realizes the early examination of arterial function and cardiovascular and cerebrovascular diseases. Regular inspection of arteriosclerosis degree is an important measure for cardiovascular disease prevention.

Nuclear magnetic resonance equipment PCB assembly:

It is an imaging technology that collects the signals generated by the magnetic resonance phenomenon and reconstructs the image, so it is also called nuclear magnetic resonance CT.

CT Scanner PCB Assembly:

CT scanners typically use PCB-based electronics.

Medical Wearable PCB Assembly:

Portable medical or health electronic devices that can be worn directly on the body.

Ventilator PCB assembly:

Ventilators are increasingly used in emergency and critical rescue, anesthesia, postoperative recovery, respiratory therapy and respiratory maintenance, and occupy an important position in medical equipment.

Kingford provides one-stop PCB manufacturing and assembly medical equipment solution services, and provides high-reliability PCB manufacturing and assembly services for the medical and health industry. Our goal is to provide our customers with high-quality medical PCBA processing services, while maximizing the To reduce costs for customers, if you are looking for a one-stop medical PCB manufacturing and assembly service provider, then kingford is your best choice.