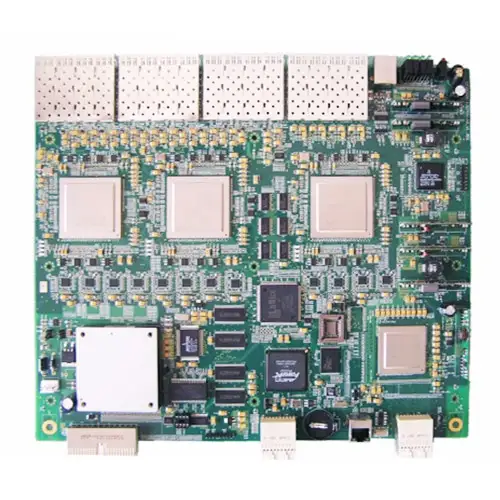

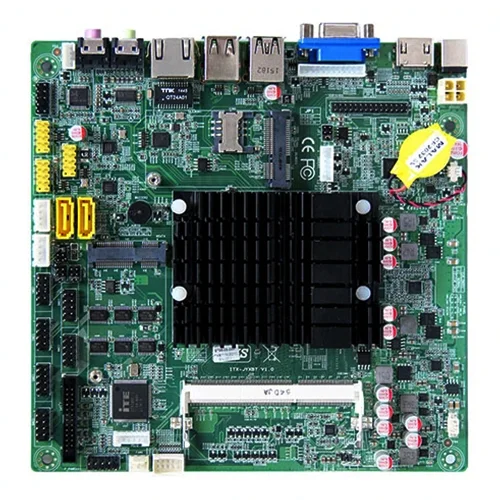

Precision Medical Equipment Circuit Board PCBA RoHS PCB Board Assembly

Name:Precision Medical Equipment Circuit Board PCBA RoHS PCB Board Assembly

Metal Coating:Silver,Copper,Gold,Tin

Mode of Production:SMT

Layers:Multilayer

Base Material:Fr4 Tg130,150,Tg170 /Aluminum

Certification:RoHS, ISO

Customized:Customized

Condition:New

Solder Mask Color:Black.Red.Yellow.White.Blue.Green

Testing Service:Aoi+100% Electrical Test

SMT Efficiency:BGA.Qfp.Sop.Qfn.Plcc.Chip

PCBA Service:One Stop Turnkey PCBA Service

Copper Thickness:1 Oz, 0.5-6oz

Supplier Type:OEM/EMS

Min. Hole Size:0.2mm

Min. Line Spacing:0.075m

Min. Line Width:0.127mm

Layer Available:1-24 Layers PCB Board

Transport Package:Anti-Static Packing

Specification:can make Blind Vias+Controlled Impedance+BGA

Origin:China

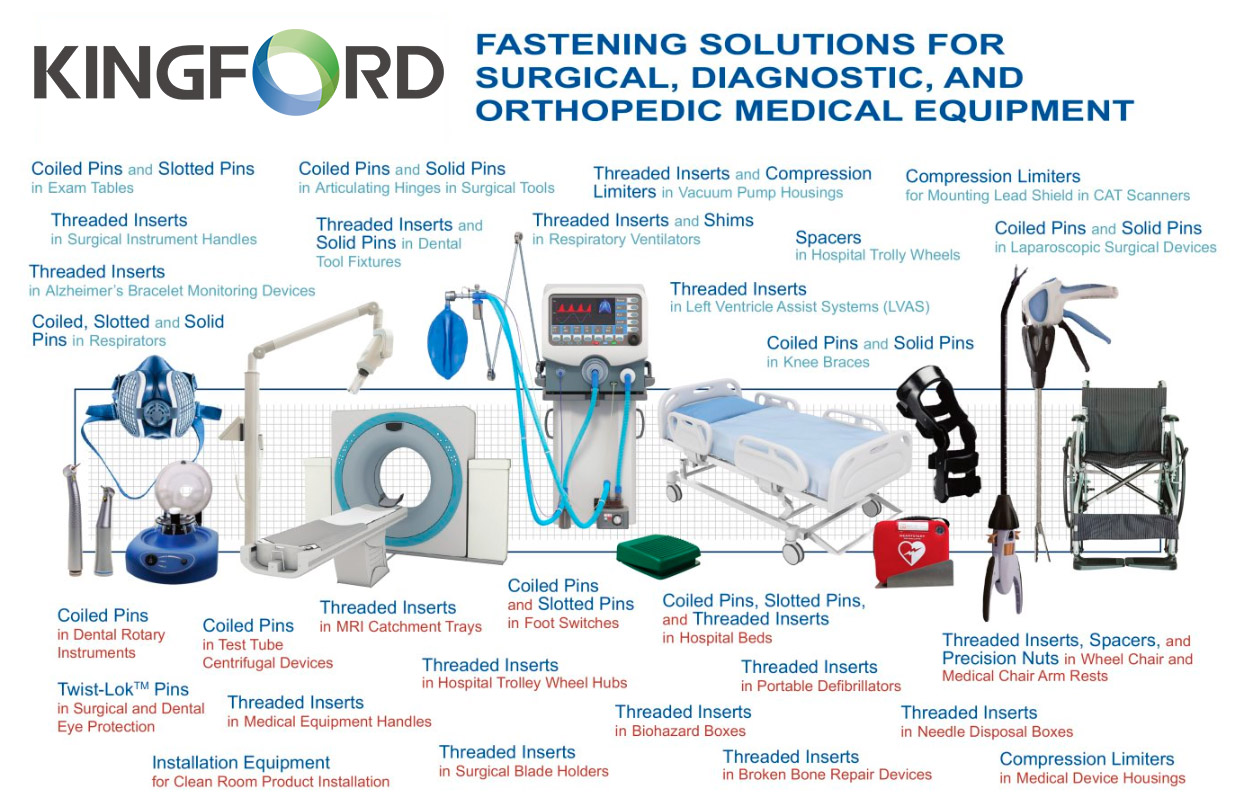

With the current Covid-19 pandemic occurring, weaknesses in the nation’s supply of medical equipment have been revealed. News outlets have reported on breakdowns with overseas shipments of vital medical equipment due to shelter-in-place policies, as well as geo-political delays that seem unlikely to resolve quickly. Quality also seems to be an issue, since China has implemented more export inspections: All these factors will motivate the U.S. medical equipment industry to relocate some of its manufacturing back to the United States. This will lead to opportunities fabricating and coating the parts needed to make respirators/ventilators, N95 masks, other PPE supplies, hospital beds, etc. An uptick in this part of the manufacturing and finishing market is already underway.

All these factors will motivate the U.S. medical equipment industry to relocate some of its manufacturing back to the United States. This will lead to opportunities fabricating and coating the parts needed to make respirators/ventilators, N95 masks, other PPE supplies, hospital beds, etc. An uptick in this part of the manufacturing and finishing market is already underway.

One of the preferred coatings for steel or aluminum medical equipment is powder coating. This is due to its superior hardness/durability and chemical resistance. The chemical resistance of polyester powder makes it one of the most easily sanitized painted surfaces. Polyester powder coating is resistant to all the CDC-recommended sanitization chemicals, such as distilled water, bleach, hydrogen peroxide, ammonia, alcohol, phenolics, steam, and UV light, per the BIMFA clean guide:

Some hospitals and laboratories are specifying anti-microbial coatings. These coatings contain a small amount of silver that is safe for human contact but inhibits the growth of microbes. This requires a specialty powder that is applied just like any other polyester powder. It also has been used for children’s playground equipment and food processing equipment. Powder manufacturers such as PPG have product lines for these applications:

There are immediate and future opportunities for fabricators and coating shops. Large medical equipment manufacturers will be setting up new operations in the U.S. They are going to need fabricated carts, frames, furniture, electronics housings, and durable parts that meet the needs of healthcare facilities in the United States. Other industries might migrate to more durable finishes as well, due to the sanitization-friendly nature of powder coatings.

We provide Precision Medical Equipment Circuit Board PCBA RoHS PCB Board Assembly services. Kingford is your one stop turnkey PCB assembly factory. Looking forward to your inquiry.

Name:Precision Medical Equipment Circuit Board PCBA RoHS PCB Board Assembly

Metal Coating:Silver,Copper,Gold,Tin

Mode of Production:SMT

Layers:Multilayer

Base Material:Fr4 Tg130,150,Tg170 /Aluminum

Certification:RoHS, ISO

Customized:Customized

Condition:New

Solder Mask Color:Black.Red.Yellow.White.Blue.Green

Testing Service:Aoi+100% Electrical Test

SMT Efficiency:BGA.Qfp.Sop.Qfn.Plcc.Chip

PCBA Service:One Stop Turnkey PCBA Service

Copper Thickness:1 Oz, 0.5-6oz

Supplier Type:OEM/EMS

Min. Hole Size:0.2mm

Min. Line Spacing:0.075m

Min. Line Width:0.127mm

Layer Available:1-24 Layers PCB Board

Transport Package:Anti-Static Packing

Specification:can make Blind Vias+Controlled Impedance+BGA

Origin:China