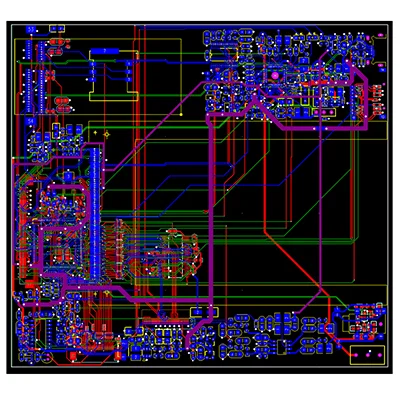

8-layer communication PCB/PCBA design

Name: 8-layer communication PCB/PCBA design

Sheet: IT180, F4BM, FR4, FR1-4, etc.

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Surface treatment: rosin spray tin electric gold, anti-oxidation, chemical gold, carbon oil

Service: Provide OEM service

Communications PCBs are also used in general telecommunications systems such as cell towers, satellites, high-speed routers and servers, and commercial telephony. Telecom PCBs are also frequently used to control LED displays and indicators.

The high-frequency hybrid splint includes a base plate, which is folded and positioned on the first inner wire layer, the first outer wire layer, and the top surface of the solder mask ink layer from top to bottom in order from bottom to top. The second layer of solder resist ink layer, the substrate includes a high-frequency area and an auxiliary area, the auxiliary area is finally fixed, and the inlay in the high-frequency area should be located at a fixed position. The utility model provides a high-frequency hybrid splint, which is divided into two parts: a high-frequency area and an auxiliary area. Provide mechanical support. The utility model discloses that the high-frequency area is independently arranged, and only the high-frequency area is made of high-frequency materials. Under the condition of satisfying high-frequency signals, the use of high-frequency board materials is minimized and the production cost is reduced.

Name: 8-layer communication PCB/PCBA design

Sheet: IT180, F4BM, FR4, FR1-4, etc.

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Surface treatment: rosin spray tin electric gold, anti-oxidation, chemical gold, carbon oil

Service: Provide OEM service