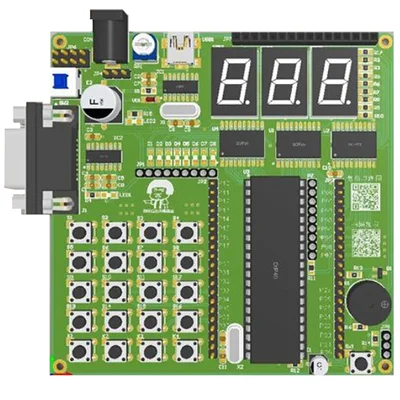

4 Layer Controller PCB/PCBA Design

Name: 4 Layer Controller PCB/PCBA Design

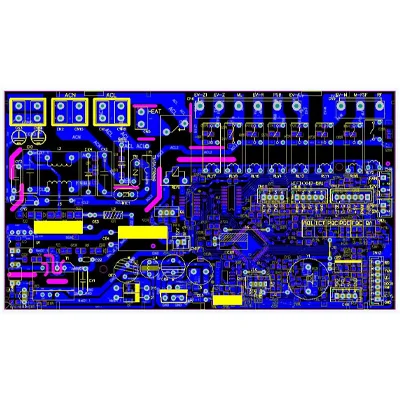

Sheet: IT180, F4BM, FR4, FR1-4, etc.

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Surface treatment: rosin spray tin electric gold, anti-oxidation, chemical gold, carbon oil

Service: Provide OEM service

A 4-layer PCB means that there are 4 layers to route electrical signals: top layer, inner layer 1, inner layer 2, and bottom layer. The top and bottom layers are the outer layers where we place our components and wiring. Inner 1 and Inner 2 are located in the core and are typically used as power planes or for signal routing. So, 4-layer PCB = 3 signal layers + GND layer or 4-layer PCB = 2 signal layers + VCC layer + GND layer.

Name: 4 Layer Controller PCB/PCBA Design

Sheet: IT180, F4BM, FR4, FR1-4, etc.

Designable layers: 1-32 layers

Minimum line width and line spacing: 3mil

Minimum laser aperture: 4mil

Minimum mechanical aperture: 8mil

Copper foil thickness: 18-175цm (standard: 18цm35цm70цm)

Peel strength: 1.25N/mm

Minimum punching hole diameter: single side: 0.9mm/35mil

Minimum hole diameter: 0.25mm/10mil

Aperture tolerance: ≤φ0.8mm±0.05mm

Hole tolerance: ±0.05mm

Hole wall copper thickness: double-sided/multi-layer: ≥2um/0.8mil

Hole resistance: double-sided/multi-layer: ≤300цΩ

Minimum line width: 0.127mm/5mil

Minimum pitch: 0.127mm/5mil

Surface treatment: rosin spray tin electric gold, anti-oxidation, chemical gold, carbon oil

Service: Provide OEM service