Did you know that almost every gadget or electronic device you use in your daily life has a basic component in common? Almost any electronic device, including your PC, laptop, smartphone, game console, microwave oven, TV, dishwasher, etc., will not work properly without PCB assembly. So, what is PCB assembly?

What does a PCB component mean? PCB assembly refers to the process of welding and assembling electronic components on preforms and fabricating printed circuit boards (PCBS). Usually using professional production machinery, mass production, T printed circuit board assembly process is commonly known as PCBA.

The difference between PCB and PCBA

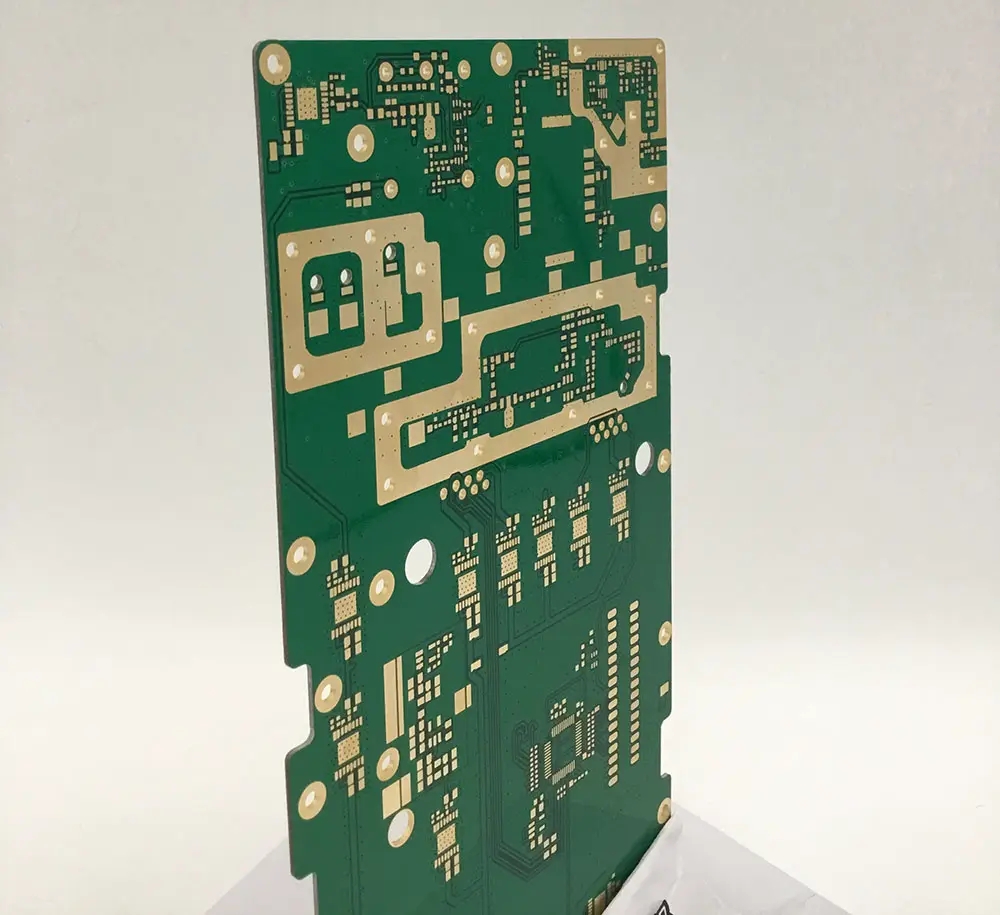

PCB refers to an empty circuit board. In this state, the board contains no electronic components and looks like green slate with dividing lines and spaces. Therefore, the PCB itself cannot be used for work unless and until the entire assembly is complete.

On the other hand, PCBA is also known as the process of welding and assembling electronic components on circuit boards and finished/assembled circuit boards. The finished PCBA is actually used for electronic devices rather than PCBS.

What is a circuit board component

The board components participate in various steps. This is a nonlinear process, indicating that factors need to be considered, and the process can change and adjust according to these factors. The expected results and usage of PCBA are one of the main considerations in determining the component and general circuit board assembly process.

The following are some of the parts and components needed to be carried out for the PCB assembly:

1, basic printed circuit board or substrate

2. Electronic components to be installed on the circuit board. It depends on the use of the board and the complexity of the device. For example, PCBA for radio is relatively simpler than PCBA for computers. In fact, some computers can have as many as 12 different circuit layers on the PCB.

3, solder material, solder wire, solder paste, prefabricated rod and other welding materials. Prefabricated rods depend on the type of welding to be performed.

4, flux, other welding equipment such as welding table, wave welding machine, inspection, testing equipment and SMT equipment. The use of equipment depends on expected results, cost and time resources. For example, reflow soldering processes used in electronics are mainly gas phase and infrared. Choose one of these processes based on the above factors. When all the necessary components are in place, the assembly process can begin. But before we get into the assembly process (which is of a different type), let's learn more about the board itself.

There are three main types of printed circuit boards

Circuit boards are usually made of epoxy resins or other composite materials. It is used to physically support components and electrically connect them to form real-time circuits. In the simplest sense, a PCB will consist of a thin layer of insulation and a layer of copper foil, jointly laminated onto the underlying substrate (usually made of epoxy, fiberglass, or similar composite materials). The number of layers on the PCB depends on the purpose and application. The lines or circuit traces on the PCB are created with the help of chemical etching. These lines help the current flow and connect the various components together. There are different types of circuit boards or PCBS. Depending on the type of application, the manufacturer will select the PCB.

Here are some of the most widely used PCB types:

PCB comes in a variety of layers, including single and double sided. However, due to its limited application range, amateurs use single sides, and double sides are usually no longer used for large-scale manufacturing. Multilayer PCBS are more common because they push the envelope behind the double-sided PCB. There can be multiple layers of substrate in this PCB. The insulating material acts as a barrier between the medium and these plates. Multilayer PCBS are designed to save more space than double-sided PCBS. Typically, multilayer boards have 4,6,8, and 10 layer options, but can be customized to have more layers. These PCBS can be used in computers, medical machines, smartphones and servers.

Rigid PCB

PCB not only has different levels of layers and sides, but also has rigidity. Usually, when we talk about PCBS, we mean rigid PCBS. These types of circuit boards use strong, non-flexible substrate materials such as fiberglass, epoxy, etc. As a result, the plate does not bend easily and provides mechanical support for the components and device as a whole. The motherboard of a computer is a common example of a rigid PCB.

Flexible PCB

Flexible PCB is directly opposed to rigid PCB. As the name suggests, these boards are made of flexible substrate materials, such as plastic. The substrate material provides enough flexibility for the plate to adapt to a variety of shapes and sizes. However, the flexibility is maintained in a way that does not damage the circuit on the board. Flexible PCBS are generally more expensive to design and manufacture than rigid PCBS. However, there are many advantages, such as the need to replace heavy-duty wiring in advanced equipment to increase space and reduce weight output. Like rigid PCBS, flexible PCBS may also be single-sided, double-sided, and multi-layered.

Metal core PCB

Metalcore PCBS or others called MCPCBS are PCBS that are specifically designed for determinative purposes. For example, the LED industry is developing rapidly, but they cannot effectively solve the problem of heat dissipation. Using MCPCB, you can solve this problem. Metal core PCBS are made of sheet metal, copper foil and thermal insulation. All in all, PCBS have magnetic conductivity, excellent heat dissipation, high rigidity and high processing power. In this case, the base materials are usually aluminum and copper. However, copper is known to outperform aluminium and is also more expensive.