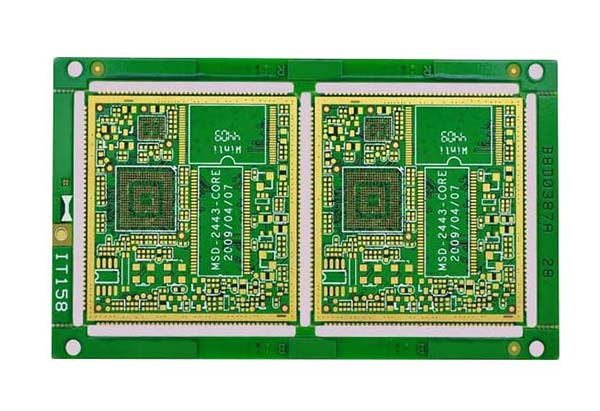

Wearable devices are used to accurately monitor the user's health status and provide medical staff with powerful information, which can effectively record the user's exercise and heart rate, etc. With the continuous development of the medical and health field, wearable device PCB manufacturing and Printed Circuit Board Assembly Become more and more complex, smart wearable medical technology requires efficient PCB electronic design, Kingford can provide medical wearable PCB one-stop service from PCB design, DFM service, PCB manufacturing, PCB assembly and so on.

We design flexible PCBs for medical wearable technology, the flexible PCBs used in this device make the device user-friendly, functional and aesthetically pleasing and meet the needs of users, the flexible PCBs we provide are made of lighter materials, flexible PCBs can make Devices are easier to form into various shapes, and when designing flexible PCBs, we also ensured the robustness of medical wearable PCBs.

We have witnessed the changing trends in the medical wearable PCB assembly industry, which makes us the most favored and valuable manufacturing partner, and we strictly follow the quality management system requirements when assembling wearable devices, insisting only on high quality PCB assembly products.

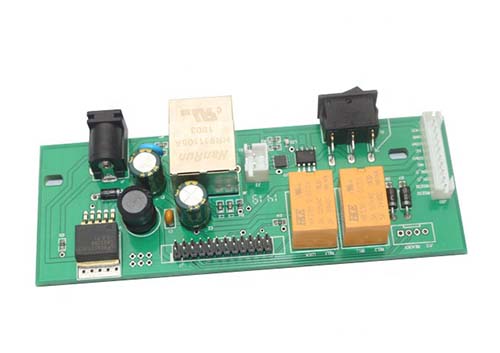

Medical wearable Printed Circuit Board Assembly performance parameters:

Copper Thickness: 1 oz

Substrate: FR4

Maximum board size: : 635 X1000 mm

Layers: 1-50 layers

Plate thickness: 1.6MM, 1.6mm-3.2mm

Copper Thickness: 1 oz

Surface treatment: HASL / ENIG

Solder mask color: green, yellow, red, black, blue, white

Screen printing color: white black grey