How to improve the direct pass rate of PCBA processing and manufacturing?

Due to the complexity of PCBA manufacturing process and various processes, the pass through rate in the process of PCBA production is not very high. Sometimes, due to some factors, batch repair may occur, increasing the manufacturing cost of PCBA production. How can we improve the pass through rate of PCBA production?

To improve the pass rate of PCBA production, we can start from the following aspects.

1. Perform DFM analysis

As the engineers of electronic product design are not very familiar with the process flow of PCBA production, PCB design may not conform to the manufacturing process. Therefore, after confirming the cooperation with customers, PCBA processing plants will generally analyze the structure of PCB, put forward suggestions for improvement, optimize the layout of circuits and components, and make it more suitable for the requirements of manufacturing process, which makes it possible to improve the pass through rate of PCBA production.

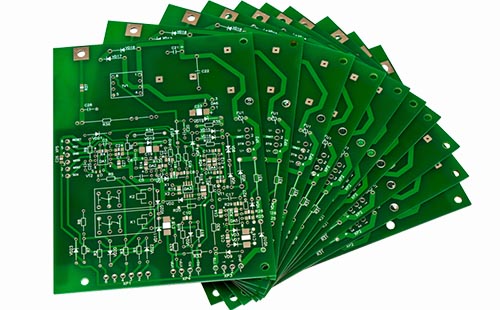

2. Select excellent PCB boards

The pass rate of PCBA production is closely related to the quality of PCB. The first choice is to select a high-quality PCB manufacturer. A+grade can be selected for the board. The surface treatment adopts the gilding process, which can produce a high-quality PCB board, which helps to improve the tin coating effect and PCB heat resistance during PCBA production, and reduce the defective rate caused by PCB quality.

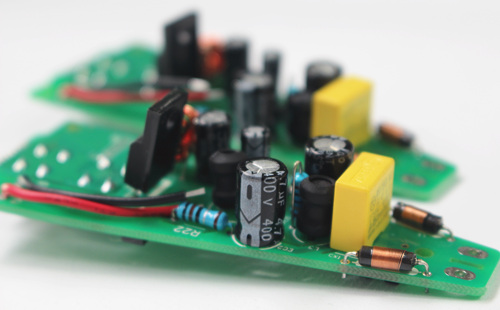

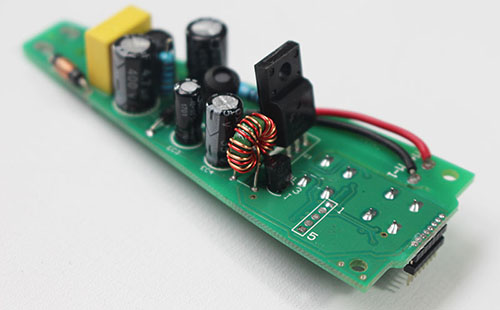

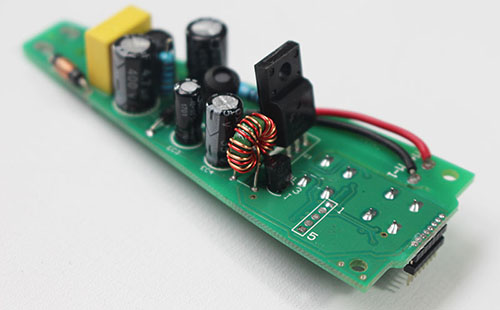

3. Optimize SMT process

Before production, some important components should be baked to remove water from the body. Famous solder pastes are selected. Many welding defects are caused by the quality of solder pastes. The steel mesh is well made, so that the solder paste can be better missed on the bonding pad. To improve the quality of solder paste printing, many welding problems are caused by solder paste printing. Only strict control of the quality of solder paste printing can effectively improve the pass through rate of PCBA production. Finally, reasonable furnace temperature curve should be set to improve the yield of PCBA welding.

4. Improve employee stability

As we all know, the staff mobility of electronic processing plants is very high and the stability is poor. Therefore, there will be a group of new employees in many electronic processing, which is an important reason for the poor pass rate of PCBA production. PCBA processing plant can publicize good corporate culture to employees, establish a good working atmosphere, improve the vitality of employees, and open a good channel for employees to rise, so as to maintain the stability of employees.

The pass through rate of PCBA production is basically less than 100%, but the pass through rate of PCBA production also reflects the overall strength of a PCBA processing plant. In order to improve the pass through rate of PCBA production, it is also necessary to constantly optimize the process flow, maintain the stability of employees, and improve the overall technical level of employees.