The car safety system includes two aspects. The first is the active safety system and the second is the passive safety system. The active safety system is to prevent accidents from happening, while the passive safety system refers to the protection of the car from collision with the members of the car or pedestrians in the event of an accident. protection of. Security systems prevent vehicle theft by providing automatic locking or remote locking and alerting when potential theft is detected, often using flexible multi-layer and HDI PCBs.

Automotive PCBs must pass a series of rigorous tests such as thermal cycling, thermal shock, and temperature and humidity before being mounted on a vehicle. Therefore, choosing the substrate material best suited for a specific application is critical. For example, heavy copper PCBs use thicker copper layers to better withstand critical conditions such as high temperature, frequency and current variations. Common boards are between 25µm and 50µm thick, while thick copper PCBs are between 150µm and 200µm thick, and these PCBs are used in security and signaling systems.

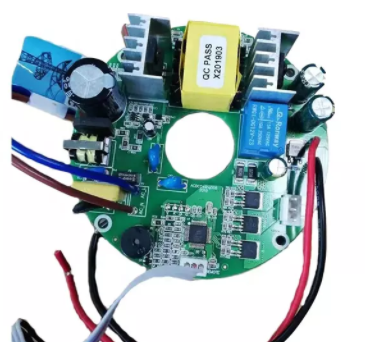

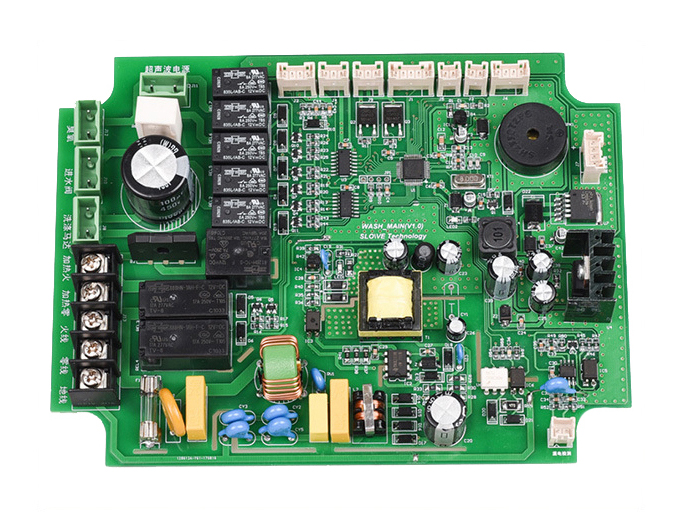

For the automotive safety system, Kingford can provide one-stop PCBA services from automotive safety system PCB design, DFM services, PCB manufacturing, PCB assembly, component procurement, etc. Currently, it has passed the IATF16949, ISO9001 and other system certifications, and has been continuously for more than 20 years. Focus on prototype and low-volume PCB production assembly.

Automotive safety system PCB assembly performance parameters:

Substrate: FR4

Copper Thickness: 0.5-4OZ / 1 Oz / 2Oz or customized

Plate thickness: 1.6mm

Hole size: 0.3mm

Line width: 0.15mm

Line spacing: 0.15mm

Surface treatment: tin spray, immersion gold, flash gold, silver plating, OSP

Board Size: 2,4,6,8,10,12,14,15,16,18,20...

Certificate: ISO9001

Testing Service: 100% AOI Testing

Material: FR4/Aluminum/Ceramic CEM1