What are the production materials of PCBA circuit board?

Printed circuit board materials

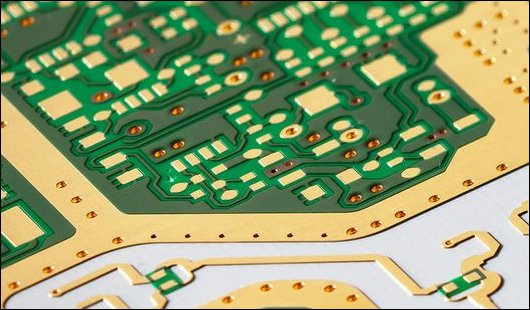

Printed circuit board (PCB) materials usually include substrate, laminate, copper foil, solder mask and nomenclature (silk screen). Different materials used in pcba processing and manufacturing have various advantages and disadvantages. PCB designers should select appropriate materials according to the application field, expected results, environmental factors and other limitations faced by PCB

The Importance of PCB Materials in PCBA Production

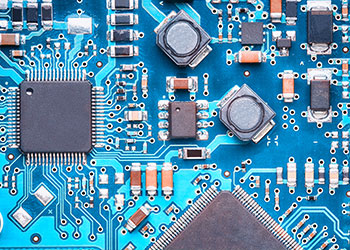

PCB manufacturing is a complex process. All materials and manufacturing steps need specific materials to realize corresponding functions. Whether these materials are left on the board or removed in the manufacturing process, they will affect the manufacturability, reliability and performance of the final product of PCB.

In addition, the choice of PCB materials will also affect manufacturing costs. Cost priority or performance priority is also an important factor in selecting materials. Therefore, when selecting PCB materials, we should understand the electrical requirements and project budget of a given equipment.

Some details about common PCB materials

Substrates and laminates

Substrate is the most selected material among PCB materials. According to different requirements, various standard substrates can be used to manufacture PCB. Typical substrates include FR-1 to FR-6, CEM-1 to CEM-6, GEM-10 to GEM-11, aluminum, metal substrates, PTFE (Teflon), polyimide, etc. Among them, FR-4 is the most commonly used material because of its wide use and low cost.

The substrate and laminate together define the necessary electrical, mechanical and thermal properties of the circuit board.

Copper foil

Copper foil is the conductive layer of PCB, which has special influence on the electrical performance of electronic products. Copper foil is generally divided into rolled copper foil and electrolytic copper foil. Calendered copper foil is suitable for high-performance PCB, and electrolytic copper foil is suitable for conventional PCB.

Solder mask

The color of solder mask is usually green for most people, but it can also be red, yellow, blue or other colors due to some special requirements. The welding resistance layer is an epoxy resin coating, which plays the role of protection and isolation layer.

Nomenclature (silk screen)

The silk screen is usually the white letter you see on the solder mask, which indicates the position and direction of the component. In addition to white, silk screen also has other colors to choose from.

Some factors that affect PCB designers' choice of PCB materials.

Thermal performance

Dielectric constant (Dk)

Glass transition temperature (Tg)

Coefficient of thermal expansion (CTE)

Nonflammable

Signal loss factor

Mechanical strength

RoHS/UL

Most customers want to manufacture PCB with excellent performance at an economical cost. The first step is to select the appropriate material for your PCB type. The unique characteristics of these materials are of great significance to determine the function, performance and life cycle of PCB. If you would like to know more about PCB material selection or how to select the best material for your PCB design, please contact us. We not only provide high-quality materials, but also provide complete solutions. You will get smaller, more intelligent, excellent performance and high reliability PCBs from Jingbang.