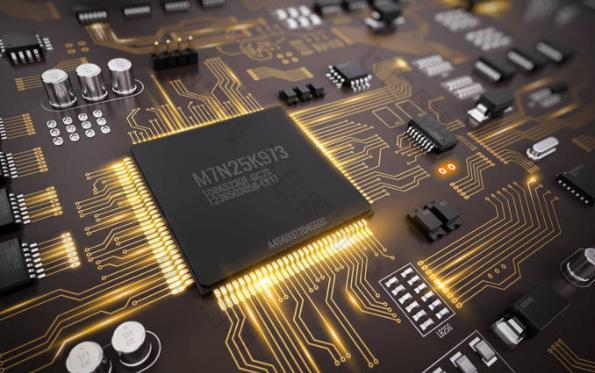

Type and selection of chip factory processing

This smt patch is processed in most areas of the electronic manufacturing industry in this factory It is no exaggeration to say that where there are industrial parks and smt patch factories, no matter the size This is the result of the high development of the electronic industry in the electronic manufacturing industry. Let's learn about the types and options of SMT patch processing!

SMT chipfactories are roughly divided into the following categories

One is a customized processing plant, which only produces for specific industries or specific products For example, there are only mobile phone motherboards, tablet computers, automotive electronics, FPC software boards, LED lights, and LED display screens All their machines, auxiliary equipment, personnel matching and testing tools are matched with this product Although only one product is produced, it is also called data processing externally If your products are not made by them, I suggest you look at other houses

The other is a large processing plant with large scale, many mechanical production lines and high production capacity. Specifically, it is divided into two types: high-end quality and low-end low-cost. These two production methods are completely understandable. If your products are simple and large in quantity, then choose low-end products. In that case, the price will be cheap. On the contrary, your circuit board has high added value, complex circuit board and high precision, so you need to look carefully to find out its quality type.

In order to meet the customer's requirements, achieve the intended use, or comply with the mandatory provisions of government laws and regulations, the smt patch factory of the processed product must generally specify its technical performance, safety performance, compatibility efficiency, as well as its impact on the environment and personal safety and health These regulations constitute product quality regulations Different products have different quality regulations, and the same product has different quality characteristics regulations, which are used for different purposes

Due to the long round-trip distance of movie titles, this format is limited in speed. At present, most OEM alternative materials use vacuum nozzles to take out materials at the same time (up to 10), and use a dual beam system to improve the speed. In other words, the pasting head on one beam takes out data, while the pasting head on the other beam almost pastes parts at twice the speed of the single beam system. However, in practical applications, it is difficult to achieve the conditions for simultaneous retrieval of data. In addition, different vacuum nozzles need to be replaced according to the type of parts, and the replacement of nozzles has a time delay.

The advantages of this model are simple system structure and high accuracy. It is applicable to parts of various sizes and shapes, even special-shaped parts. There are three types of feeder: belt, pipe and tray. It is suitable for medium and small batch production, and the combination of multiple machines can also be used for mass production.

The product quality inspection of processed products is usually based on its parameter characteristics Through physical, chemical and other scientific and technological means and methods, observation, experiments and measurements can be carried out to obtain objective evidence to confirm product quality Therefore, the smt patch factory for quality inspection of processed products needs appropriate inspection methods, including various measuring and testing instruments, instruments, testing equipment, etc Effective control to maintain accuracy and accuracy

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.