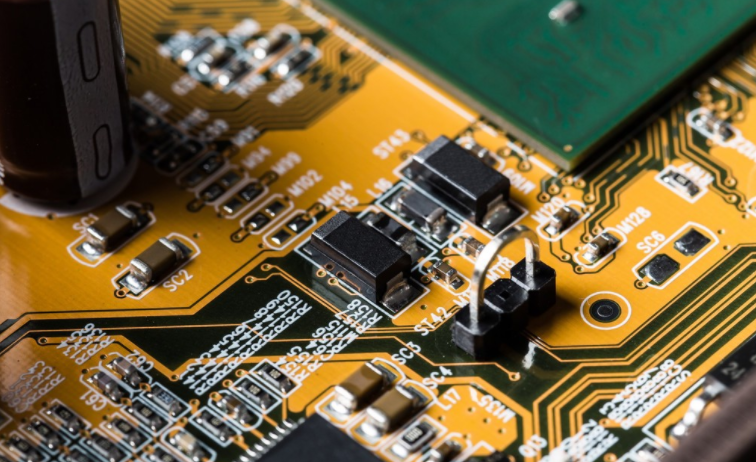

SMT Reflow Technology Welding Requirements

SMT welding is an important process in electronic board assembly If the master is not good, not only will there be many "temporary failures", but it will also directly affect the life of solder joints

Almost all thermometers are available, but there are still many users who do not carry out temperature measurement certification and adjust temperature settings for all products; Some users have used temperature measurement, but they have not mastered the key points of the welding process and are unable to optimize the process.

In this paper, we hope that we will encourage users to further study this subject by elaborating the principles and key points of reflow soldering, so as to better handle this technology Inside SMT reflow soldering, there are infrared technology, hot air, laser, incandescent lamp, and hot pressing Due to space and time, this article only explains the most commonly used hot air reflow technology In addition, the results of any process are comprehensive The assembly quality of PCBs is not entirely determined by the welding process

Even if it is a welding problem, such as a solder ball, it is a combination of design, data, equipment, and processes (including the variable process steps before solving) Therefore, technology integration, application and management are the fundamental ways to ensure good assembly quality With the number of processes that affect SMT (Note 1) and the variety of quality factors, it is necessary to fully explain the application of technology integration Therefore, in the limited space of this paper, only the key explanations of the welding process, and other related processes, manufacturability design, data quality, equipment capacity, etc. are given Assume in place

Basic requirements for SMT welding:

No matter what welding technology we use, we should ensure that the basic requirements for welding are met to ensure good welding effect. High quality welding shall meet the following five basic requirements.

1. Appropriate Calories

2. Good wettability;

3. Appropriate solder joint size and shape;

4. Control the direction of tin flow;

5. The welding surface does not move during welding.

Proper heat means that for all welding surface data, there must be enough heat energy to melt them and form an intermetallic interface (IMC). Sufficient heat is also one of the basic conditions for providing wetting. On the other hand, the heat must be controlled to a certain extent to ensure that the contact data (not only the welding end) will not be subject to thermal damage, and the formation of IMC layer will not be too thick (Note 2).

Wetting is not only a symbol of good solderability, but also an important condition for forming the final solder joint shape. Poor wettability usually indicates that the solder joint structure is not ideal, including incomplete IMC formation and poor solder joint filling. These problems will affect the life of solder joints.

In order to make the solder joint have enough life, it is necessary to ensure that the shape and size of the solder joint meet the requirements of the welding end structure. The mechanical strength of too small solder joints is insufficient to withstand the stress in use, or even the internal stress after welding. Once fatigue or creep cracks occur during use, the fracture speed will be faster. Poor solder joint shape will also lead to weight reduction and shorten the life of solder joints.

Controlled tin flow direction is also an important part of the welding process. The molten solder must flow in the required direction to ensure controlled solder joint formation. The use of "steal tin pad" and solder mask (green oil) during wave soldering and the phenomenon of tin absorption during reflow soldering are technical details related to the control of tin flow direction.

If the welding end moves during welding, depending on the movement and time, it will not only affect the shape and size of the welding spot, but also may cause false welding and internal holes. This will affect the quality and life of solder joints. In this case, the design and process of the whole product must pay attention to keeping the welding end static during the welding process.

In addition to the above general welding conditions, there is a special point in the SMT reflow soldering process, that is, the chemical components in the solder paste must volatilize in time after the printing process. This is especially strict on the first side of the double-sided welding process.

In design and operation, we must pay attention to the above technical requirements SMT reflow process Let's take a closer look at the SMT reflow process and its control methods and techniques

The above is the explanation given by the editor of pcb circuit board company.

If you want to know more about PCBA, you can go to our company's home page to learn about it.

In addition, our company also sells various circuit boards,

High frequency circuit board and SMT chip are waiting for your presence again.