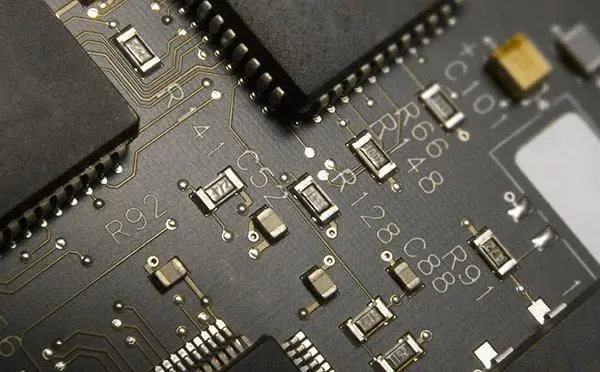

Soldering resistance will be used in the production of circuit boards. Today, I will show you the process of forming pcb solder resistance. The solder resistance pattern processing of pcb board factory is carried out after the etching of the circuit pattern on the surface of the printed board is completed. The process methods for forming resistance welding patterns are divided into two categories:

The solder mask pattern processing of pcb board factory is carried out after the circuit pattern etching on the surface of pcb board is completed. The process methods for forming resistance welding patterns are divided into two categories:

(1) Solder resistance pattern screen plate is made by direct printing with ink. Solder resistance ink is used to directly print the completed line pattern on the board, and the transfer of solder resistance pattern is completed after curing. According to the performance of solder resist ink, the pattern curing can be UV curing or thermal curing. Direct printing is generally used for simple single-sided and double-sided printed boards.

(2) Wet film photoimaging liquid photosensitive solder mask ink (wet film) is coated on the finished circuit pattern on the board; Then, the pattern is transferred by exposing the photographic plate, and the solder mask pattern is obtained on the plate surface. The wet film photoimaging method is generally used for multilayer boards and HDI boards, and has better coverage and graphic accuracy than the direct printing method.

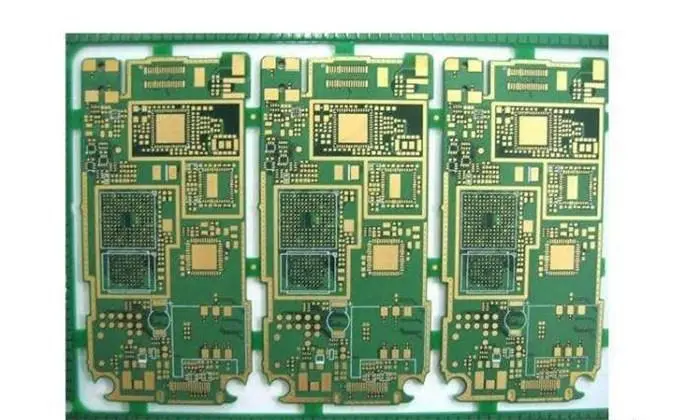

Resistance welding is a very important process in the circuit board factory. Our pcb circuit boards can be used in communication, medical equipment, and consumer electronics. They have been strictly tested and carefully inspected in the production process, and are all in line with the IPC standard for circuit boards.

In a circuit board factory, resistance welding is also a very important process. A strict quality management system is necessary

Graphic transfer technology in pcb board factory

The product complies with IPC - Ⅱ or IPC - Ⅲ standards

Use SPC control chart to control quality process

Implement PDCA cycle process to continuously improve product performance

A perfect quality assurance inspection system has been established, and professional quality assurance personnel have been assigned throughout the process