Building 6, Zone 3, Yuekang Road,Bao'an District, Shenzhen, China

+86-13923401642Mon.-Sat.08:00-20:00

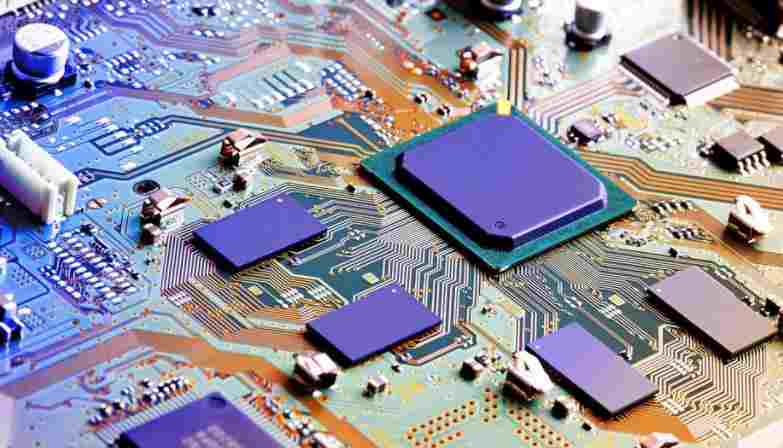

BGA storage, SMT patch or through-hole insertion technology

Precautions for BGA storage Surface mount process

With the development of electronic technology, electronic components are developing towards miniaturization and high-density integration BGA modules have been more and more widely used in SMT assembly technology. With the emergence of u-BGA and CSP, SMT assembly becomes more and more difficult and the process requirements become higher and higher Due to the difficulty of BGA maintenance, achieving good BGA welding is the theme of all SMT engineers The following mainly introduces the precautions for the storage and use of BGA

Precautions for BGA storage:

BGA components are highly temperature sensitive components. The BGA must be stored under constant temperature and dry conditions. Operators shall strictly follow the operation procedures to prevent the components from being affected before assembly. In general, the ideal storage environment for BGA is 200C-250C, and the humidity is lower than 10% RH (nitrogen protection is better).

In most cases, we will notice the moisture-proof treatment of BGA before unpacking the components. At the same time, we should also pay attention not to expose the time of component packaging during installation and welding to prevent affecting the components, reducing the welding quality or changing the electrical efficiency of the components.

The characteristics of SMT technology can be compared with traditional through hole insertion technology (THT). From the perspective of assembly process technology, the fundamental difference between SMT and THT is that the difference between "pasting" and "inserting" is also reflected in various aspects of substrate, component, component shape, solder joint shape and assembly process method.

THT uses leaded parts. The circuit connecting wire and mounting hole are designed on the printed board. Insert the component leads into the pre drilled holes on the PCB, then temporarily fix them, and use wave soldering on the other side of the substrate. Welding technology is used for welding to form reliable welding points and establish long-term mechanical and electrical connection. The main components and solder joints of the components are distributed on both sides of the substrate. With this method, because the components have leads, when the circuit density reaches a certain level, the problem of reducing the volume cannot be solved. At the same time, it is difficult to eliminate the faults caused by the proximity of wires and the interference caused by the length of wires.

The so-called SMT surface mounting technology refers to the chip structural components or miniaturized components suitable for surface mounting that are placed on the surface of the printed circuit board according to the requirements of the circuit and assembled together by reflow soldering or wave soldering and other welding processes. It constitutes a chip processing and assembly technology for electronic components with certain functions.

Differences between SMT and THT component installation and welding methods: on the traditional THT PCB, the component and solver joints are located on both sides of the board; While on the SMT circuit board, solder joints and components are on the same board Therefore, on the SMT PCB, through holes are only used to connect wires on both sides of the PCB. The number of holes is much smaller and the diameter of holes is much smaller With this kind of pipe, the assembly density of the circuit board can be greatly improved

Precautions for BGA storage Surface mount process

With the development of electronic technology, electronic components are developing towards miniaturization and high-density integration BGA modules have been more and more widely used in SMT assembly technology. With the emergence of u-BGA and CSP, SMT assembly becomes more and more difficult and the process requirements become higher and higher Due to the difficulty of BGA maintenance, achieving good BGA welding is the theme of all SMT engineers The following mainly introduces the precautions for the storage and use of BGA

Precautions for BGA storage:

BGA components are highly temperature sensitive components. The BGA must be stored under constant temperature and dry conditions. Operators shall strictly follow the operation procedures to prevent the components from being affected before assembly. In general, the ideal storage environment for BGA is 200C-250C, and the humidity is lower than 10% RH (nitrogen protection is better).

In most cases, we will notice the moisture-proof treatment of BGA before unpacking the components. At the same time, we should also pay attention not to expose the time of component packaging during installation and welding to prevent affecting the components, reducing the welding quality or changing the electrical efficiency of the components.

The characteristics of SMT technology can be compared with traditional through hole insertion technology (THT). From the perspective of assembly process technology, the fundamental difference between SMT and THT is that the difference between "pasting" and "inserting" is also reflected in various aspects of substrate, component, component shape, solder joint shape and assembly process method.

THT uses leaded parts. The circuit connecting wire and mounting hole are designed on the printed board. Insert the component leads into the pre drilled holes on the PCB, then temporarily fix them, and use wave soldering on the other side of the substrate. Welding technology is used for welding to form reliable welding points and establish long-term mechanical and electrical connection. The main components and solder joints of the components are distributed on both sides of the substrate. With this method, because the components have leads, when the circuit density reaches a certain level, the problem of reducing the volume cannot be solved. At the same time, it is difficult to eliminate the faults caused by the proximity of wires and the interference caused by the length of wires.

The so-called SMT surface mounting technology refers to the chip structural components or miniaturized components suitable for surface mounting that are placed on the surface of the printed circuit board according to the requirements of the circuit and assembled together by reflow soldering or wave soldering and other welding processes. It constitutes a chip processing and assembly technology for electronic components with certain functions.

Differences between SMT and THT component installation and welding methods: on the traditional THT PCB, the component and solver joints are located on both sides of the board; While on the SMT circuit board, solder joints and components are on the same board Therefore, on the SMT PCB, through holes are only used to connect wires on both sides of the PCB. The number of holes is much smaller and the diameter of holes is much smaller With this kind of pipe, the assembly density of the circuit board can be greatly improved

Just upload Gerber files, BOM files and design files, and the KINGFORD team will provide a complete quotation within 24h.