Share and explain the advantages of Flex FPC PCBA

Modern electronic equipment requires lightweight and durable components. Heat, vibration and moving parts will damage traditional connections. Flexible printed circuit boards provide solutions to all these potential problems and more. Using flexible PCB is beneficial in many different applications, and can work normally in almost every project. Before outsourcing the next PCBA project, consider merging the advantages of flexible circuits.

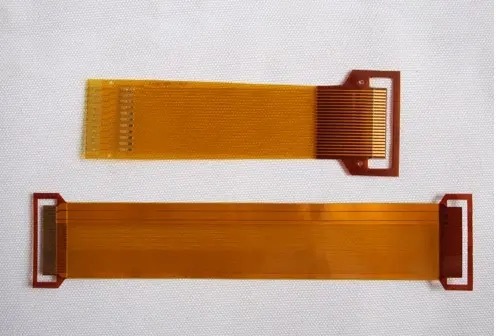

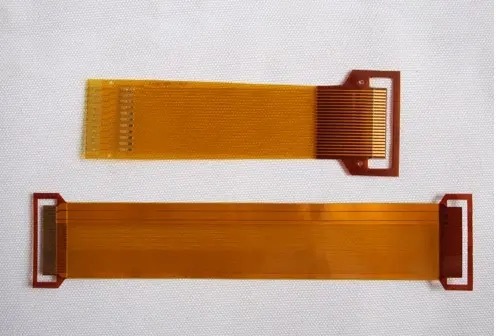

What is a Flex PCB?

Flexible PCB is a flexible circuit with very thin substrate and high level of physical flexibility. They can be molded into complex three-dimensional shapes and used in many different applications. Flexible circuits can be formed in a manner that cannot be realized by ribbon cables or rigid printed circuit boards. Flexible circuits are divided into three types, from the lowest inspection level to the highest inspection level, and five types, depending on the number of conductive layers, structure, and whether there are plated through holes.

Which applications are most suitable for FPCs?

Flexible circuit boards can be used in many different applications. The applications and uses of flexible PCB are too many to enumerate. If it is something you wear, carry or drive, it is likely to use flexible circuit technology. Although there are a variety of consumer industry applications, there has been considerable development, especially in several areas.

·Aerospace Applications

The flexibility, reliability and performance of flexible circuits make them very suitable for many equipment required by aerospace technology, including head up display, holographic waveguide helmet mounted display and silicon based liquid crystal (LCOS) display.

·Medical applications

Hearing aids, like many wearable medical devices, will benefit greatly from flexible circuit technology.

·Automotive Applications

There are many advantages in using flexible circuit technology in automobile parts. The anti vibration property of flexible circuit makes it very suitable for motor vehicles.

What are the advantages of Flex PCB?

Compared with traditional ribbon cable or flat cable, flexible PCB has many advantages. Technology is constantly striving to improve its functions, and the space we need to accommodate it is getting smaller and smaller. With the growth of this demand, flexible circuits will be particularly well able to meet the challenges.

Flexible circuits can form complex three-dimensional shapes with branches that branch to multiple connectors, but ribbon cables cannot.

Flexible circuits can be connected to rigid boards without the need for tall and bulky connectors for other cables.

Flexible circuits perform well in ultra-high vacuum environments, such as space.

Flexible circuits are lightweight, reducing the weight by up to 75% compared to other materials.

The use of flexible circuits can reduce assembly costs by reducing the number of components and interconnects. This also provides high quality efficiency for mass production.

The standardized structure of flexible circuit eliminates the potential error source of manual wiring harness.

The flexible circuit board can be made to be suitable for places where other solutions are not feasible.

The use of flexible circuits can provide more stringent bending capabilities.

Flexible circuits require less interconnects to improve reliability.

Flexible circuit technology performs well in vibration and shock environments.

Flexible circuits perform well in harsh environments.

Flexible circuits have excellent resistance to chemical, radiation and UV exposure.

When outsourcing PCBA, please consider cooperating with stores that are proficient in Flex PCB technology. There are many performance advantages, but the additional cost savings make flexible circuits worth considering. The improved reliability of flexible circuits means that your products have a longer service life and can ultimately reduce costs in the long run. Not sure if the flexible circuit is suitable for your next version? The PCB processing factory explained, shared and explained the advantages, potential problems and more problems of Flex FPC PCBA, and provided solutions.