Circuit board to be able to work normally, in addition to the hardware normal, still lack without software cooperation. Especially at present, more and more intelligent products, more and more requirements for the customization of the program, so that for PCBA processing, not only do hardware processing but also need to carry out chip burning. The following patch processing manufacturer to explain how to burn the PCBA processing chip and how to develop the relevant knowledge of PCBA products

1. How was the PCBA product developed

Good PCBA processing manufacturers also have a certain understanding of the research and development of PCBA products. These experiences can help PCBA processing plants better serve customers and enhance mutual trust. kingford is a PCBA manufacturer with research and development ability of small household appliances. Next, we will introduce the research and development process of PCBA products.

1. Market research/demand analysis/Project establishment Through market research, the product manager will produce a demand document, state the user's pain points or industry needs, analyze the solution, and describe the logical relationship clearly through text or graphics. After the requirements analysis phase, you can enter the project approval.

2. Prototype and interaction design /APP development According to the requirements document, the product manager will design the prototype diagram, including the structural layout of functions, the design of each paging plane and the design of business logic between pages, and finally output the prototype design diagram. UI designers will carry out interface-related color matching design, functional concrete processing, interaction design and adaptation of various models and systems on the prototype design drawing, and finally output the high-fidelity design drawing. APP engineer develops interface according to hi-fi design drawing; Server engineers will write API interface, server environment setup and database design; At a certain stage of development, APP engineers will connect with the server side, obtain data through the interface of the server side, and write functional logic code.

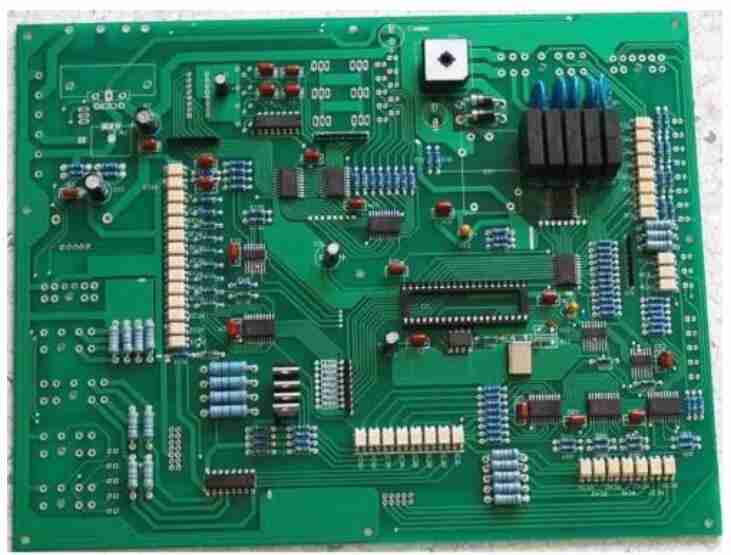

3. Hardware development After product approval, hardware engineers should start to select hardware platform according to the requirements, and evaluate from the aspects of functional requirements, performance requirements, technical support, cost evaluation and availability. The evaluation of hardware functions and performance requirements mainly refers to the selection of the main chip, which requires specific analysis and comparison of the main chip resources, storage capacity and speed, I/O port allocation, and interface resources. After the main chip is determined, other key components need to be determined according to the diversity function to achieve the optimal performance and cost of the overall scheme. After the main chip is determined, it basically determines the details of the software driver layer design. After the overall hardware scheme is determined, the development stage is entered: hardware schematic design, PCB board design and production, BOM list, PCB board patch.

2. How to burn the chip in PCBA processing

Chip burning is to write the program through the burning tool chip internal storage space, generally divided into offline burning and online burning, the next PCBA processing manufacturer kingford for you to introduce the two ways of burning. Offline burning through a variety of adapters compatible with different packages of chips, chip and adapter collocation to achieve the program burning. The adapter itself is a kind of precision fixture, different chips, different packages need to choose different adaptation base.

Now widely used chip packaging such as Emmc to BGA, QFN and other small, flat direction development, and the price of this kind of package adapter is not low. If there is an error in the production test, it is necessary to remove the chip from the adapter and burn it again in accordance with the prescribed process, which is time-consuming and costly. In the pcba processing and production, there will be some emergencies, such as the circuit board temperature resistance height is not enough, when disassembling the chip will cause chip deformation, which increases the risk of scrap. Online burning online burning is the use of the chip's standard communication bus, such as USb, SWD, JTAG, uart, etc., the interface is generally fixed, burning the need to connect the foot is less. As the interface communication rate is not high, the use of general wire can be completed burning, will not produce high consumption.

Because the online burning is through the wire connection to the program burning, if the production test found error, can immediately on the error of the PCBA backtracking, re burning, and do not need to remove the chip. It not only saves the production cost, but also increases the burning efficiency. More importantly, the production line is also developing towards automation, more and more manufacturers add ICT, FCT and other functional testing machines to the production line, the use of automatic fixture with online burning production mode can save manual operation in the burning stage, paste the board directly after burning, and then send the PCBA to the test machine test, the whole production process is fully automated. Can greatly improve the production efficiency. Therefore, in PCBA processing, online burning has significant advantages, and has become one of the important indicators to measure the process accuracy, production efficiency, cost, quality control, scale, capital and other aspects of PCBA manufacturers in the industry.