SMT machine is a very important equipment in SMT processing. The quality of SMT machine not only determines the quality of SMT processing, but also determines the efficiency of SMT processing. So, how to choose high-quality SMT patch processing machine? The following to share with you the selection skills. The following SMT processing manufacturers to explain how to choose SMT processing machine and SMT processing how to correctly select the relevant knowledge.

1. How to correctly select SMT patch processing

How to choose SMT patch processing manufacturers For consumers, naturally want to be able to choose better patch processing manufacturers, but how to choose, first of all, should be through the way of comparison. Today's enterprises have already generated many, and at the sight of all kinds of enterprises, many people will feel that some can not choose, when you choose, first of all should look at the time of the establishment of the other side, should also look at the size of the company, if the company's area is relatively large, and has already been established for 5~10 years, it also shows that it is relatively reliable, Of course, the key is to combine their own city.

If you are in a big city, it is relatively more convenient to choose processing manufacturers in your own city, and if you are in a small county, it is best to choose the nearest cooperation, so in the process of cooperation in peacetime can also bring a lot of convenience. Many people will think that since we do this kind of small processing project, there should be no high requirements. In fact, smt patch processing manufacturers should also meet the corresponding conditions if they want to operate effectively. First of all, there must be a guarantee on the power supply, the power of the power supply must obviously exceed the power consumption, to be able to normal use, otherwise there will be frequent problems. In addition, electronic components are more likely to fail, so in the process of normal operation must ensure that there is clean air can not be dust, otherwise it will naturally have an impact.

Of course, in the process of choosing operation, it is not only these simple provisions, the temperature in the workshop is best to keep at 17~28 degrees, so in the cold winter, it should be long time to open the air conditioning, which can ensure normal operation, and after entering the hot summer, it should also play air conditioning, These are all critical in operation. Thus, it can be seen that SMT patch processing manufacturers do need to meet the corresponding conditions in the operation process. Of course, for enterprises, it is natural to choose a more reliable processing manufacturer, so as to make the daily operation more convenient. These are also a major key point at present.

2. How to select SMT patch processing machine

First, accuracy

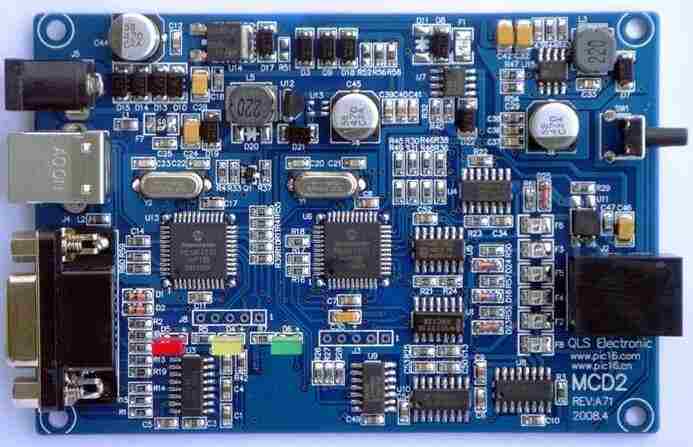

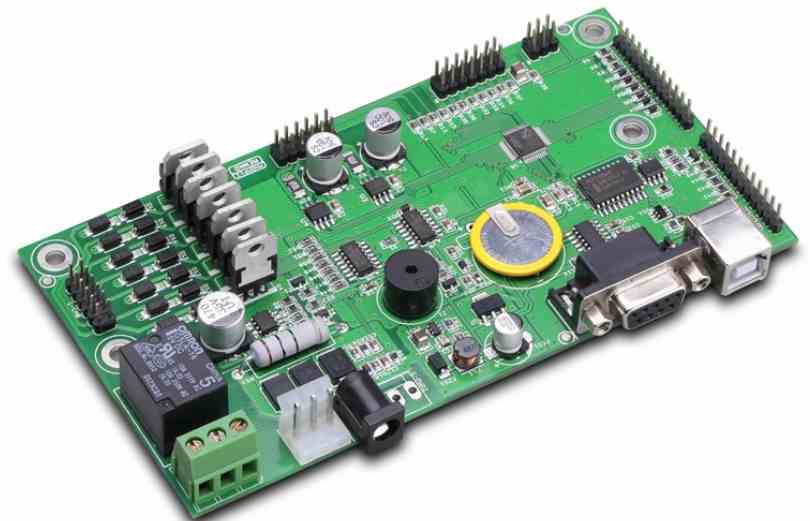

According to understand, the current quality SMT patch processing is based on the lamp bead production of electronic products welding pad, the precision requirements of these components are relatively high, and the need for a full set of visual identification system, so that you handle the various mounting Angle, avoid the appearance of incomplete installation. Therefore, when choosing SMT patch processing machine, it is necessary to choose one with visual image correction function, which can not only greatly guarantee the mounting accuracy, but also identify the multi-angle components, so as to ensure the accuracy of production.

Ii. Stability

High quality SMT patch processing machines must have good stability, so as to ensure the production of high efficiency and high quality. The stability of the patch machine not only depends on the hardware configuration of the machine, but also depends on the software function and the cooperation between the software and hardware. At present, there are a lot of SMT SMT SMT machines in the market, but there are very few truly high-quality SMT SMT processing machines, especially those who master the core technology. In this regard, Xiaobian remind do not choose SMT SMT machine without core technology. On the one hand, such a machine is prone to loopholes, and it is not easy to supplement, on the other hand, such a machine equipment hardware is very poor, in 24 hours of high-speed operation is easy to burn out, wear serious and fracture. Most importantly, if the SMT SMT machine purchased is not of high quality, it is easy to affect the production efficiency and lose customers, which is not conducive to the development of the enterprise.

Three, durability

The price of high-quality SMT patch processing machines is not low, mainly because this aspect of equipment belongs to high precision equipment, coupled with the development of SMT industry, the demand for this aspect is large, so the price of machines and equipment is not low. But for some small SMT patch manufacturers, hundreds of thousands of machines they can not afford, can only choose tens of thousands of dollars of SMT patch machine, although the performance is general, but the price is low. However, such SMT SMT machine use time is very short, basically one or two years will be replaced. Some even from the beginning of use often appear problems, let a person is very annoying. High quality SMT processing machine is different, both in precision and the hardware and software is very advanced, and 224 hours of operation are not easily fail, durable strong persistence.

Four, easy maintenance

High-quality SMT SMT processing machine because of the use of professional standardized means of production, even if the fault, maintenance is very easy. And ordinary or even ordinary quality SMT machine, once failure, it is difficult to repair. In general, the choice of high quality SMT patch processingmachines than ordinary quality machines more cost-effective. And electronic enterprise customers will also understand this information when consulting partners. Having high-quality machines can increase a lot of competitive advantages for their own enterprises.